Heavy-load type stacking unit of mold transfer trolley

A transfer vehicle and heavy-duty technology, applied in the direction of lifting devices, etc., can solve the problems of self-heavy, large self-weight and volume of transfer vehicles, large volume and weight of stacking units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

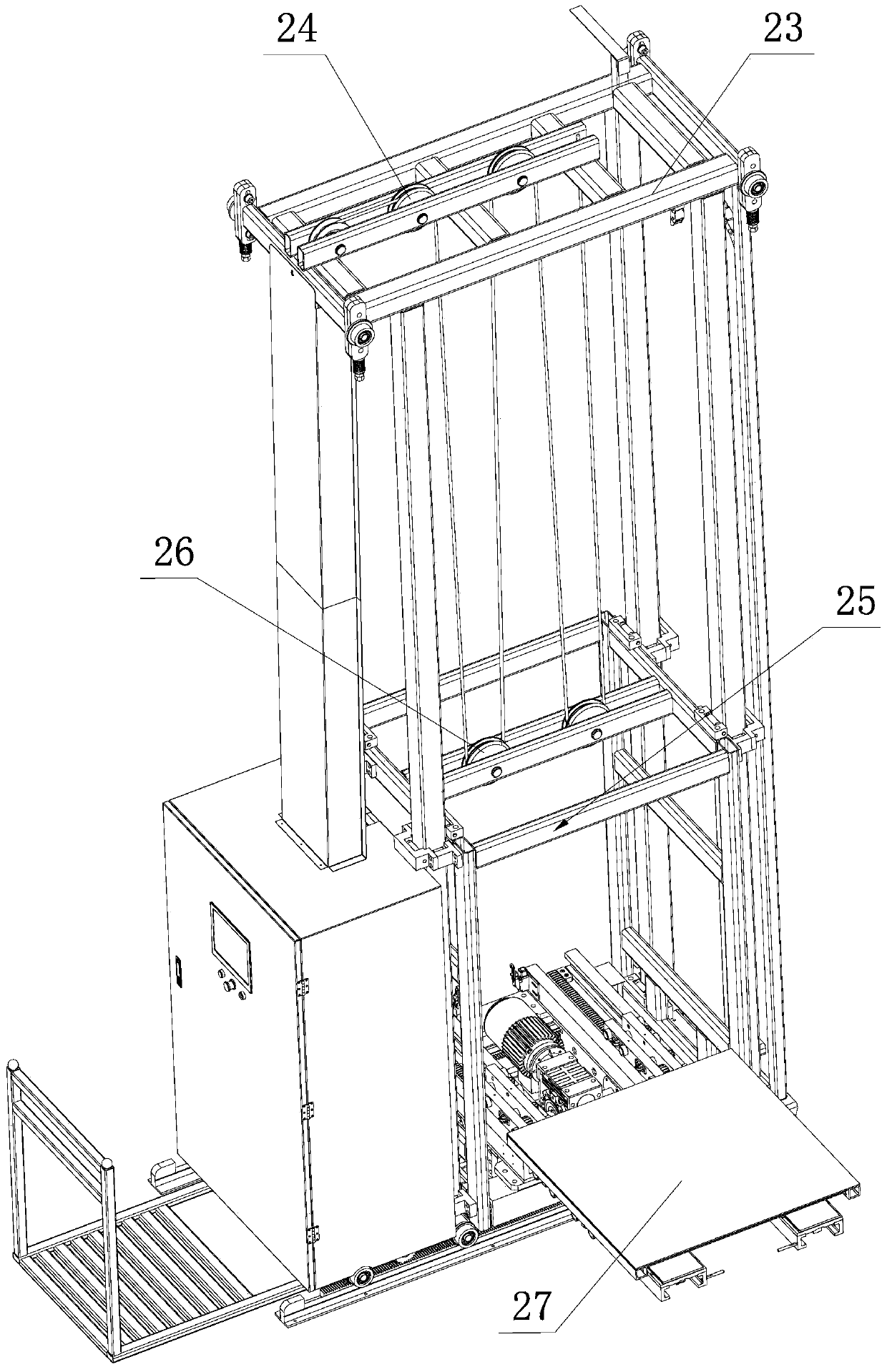

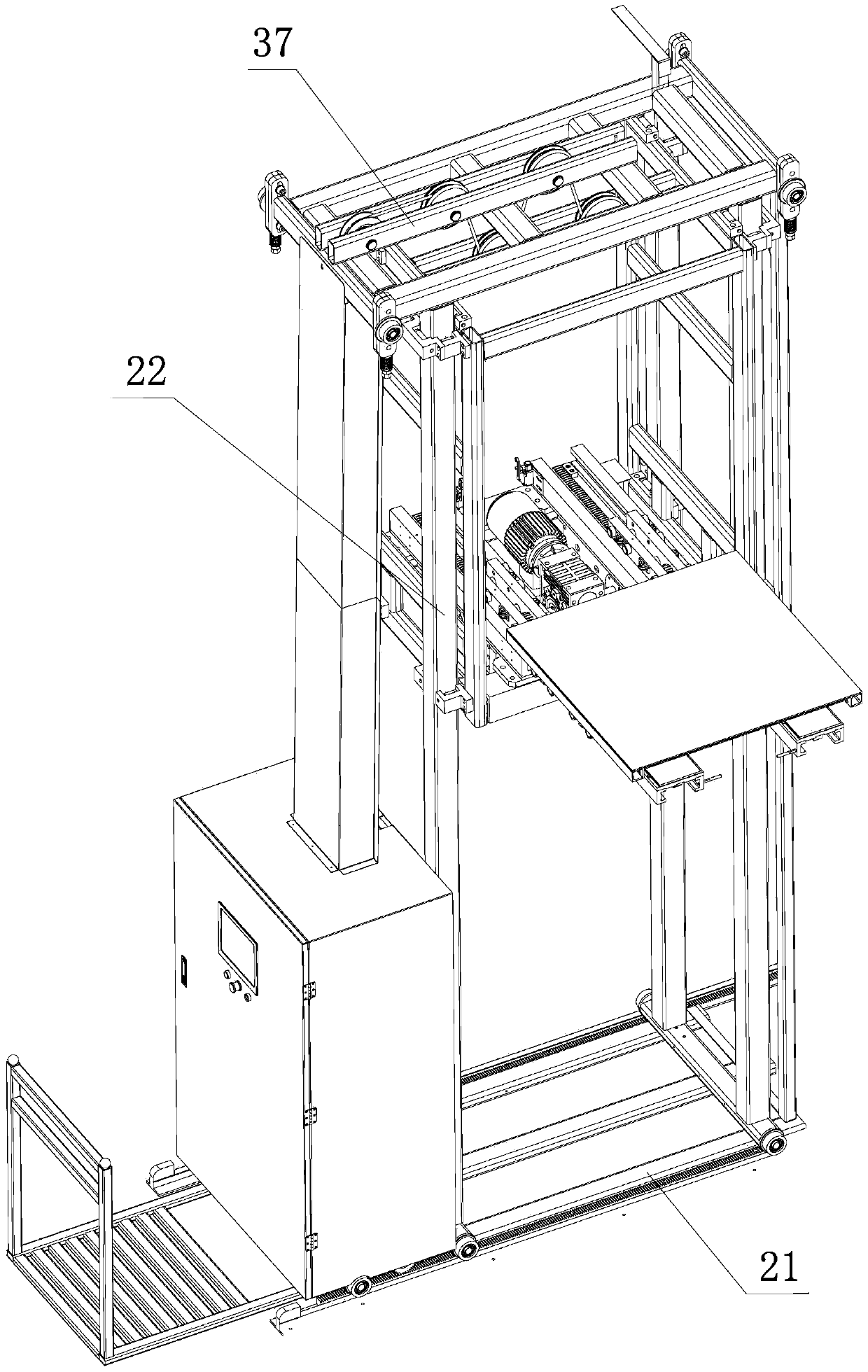

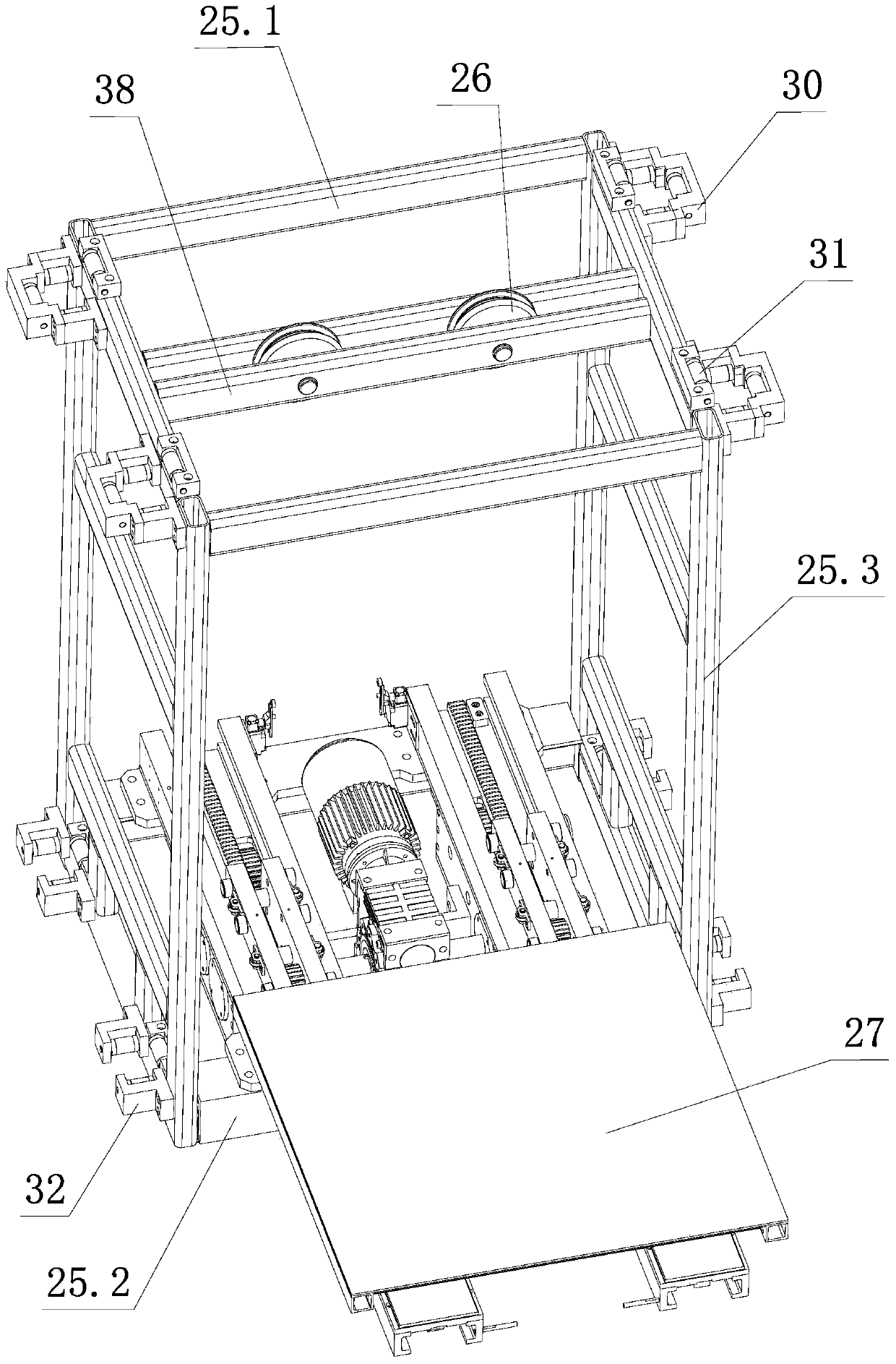

[0037] Such as Figure 1 to Figure 11 As shown, the heavy-duty stacking unit of the mold transfer vehicle of the present invention includes at least two guide columns 22 installed on the frame 21 of the transfer vehicle, and there are four guide columns 22 in this embodiment. Top frames 23 are fixed to the tops of the four guide posts 22 , specifically the top ends of the four guide posts 22 are fixed to the four corners of the top frame 23 . An upper beam 37 is provided on the top frame 23, and a plurality of fixed pulleys 24 are rotatably installed on the upper beam 37. A car 25 is slidably fitted on the four guide posts 22 . Specifically, the car 25 is composed of an upper rectangular frame 25.1, a lower rectangular frame 25.2 and four columns 25.3 connecting the two rectangular frames. The four columns 25.3 are separated from the four cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com