Luggage high-speed automatic packing device

A baggage and high-speed technology, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve problems such as low processing efficiency and baggage flow congestion, and achieve the effect of high efficiency, satisfying use requirements, and flexible and ingenious structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

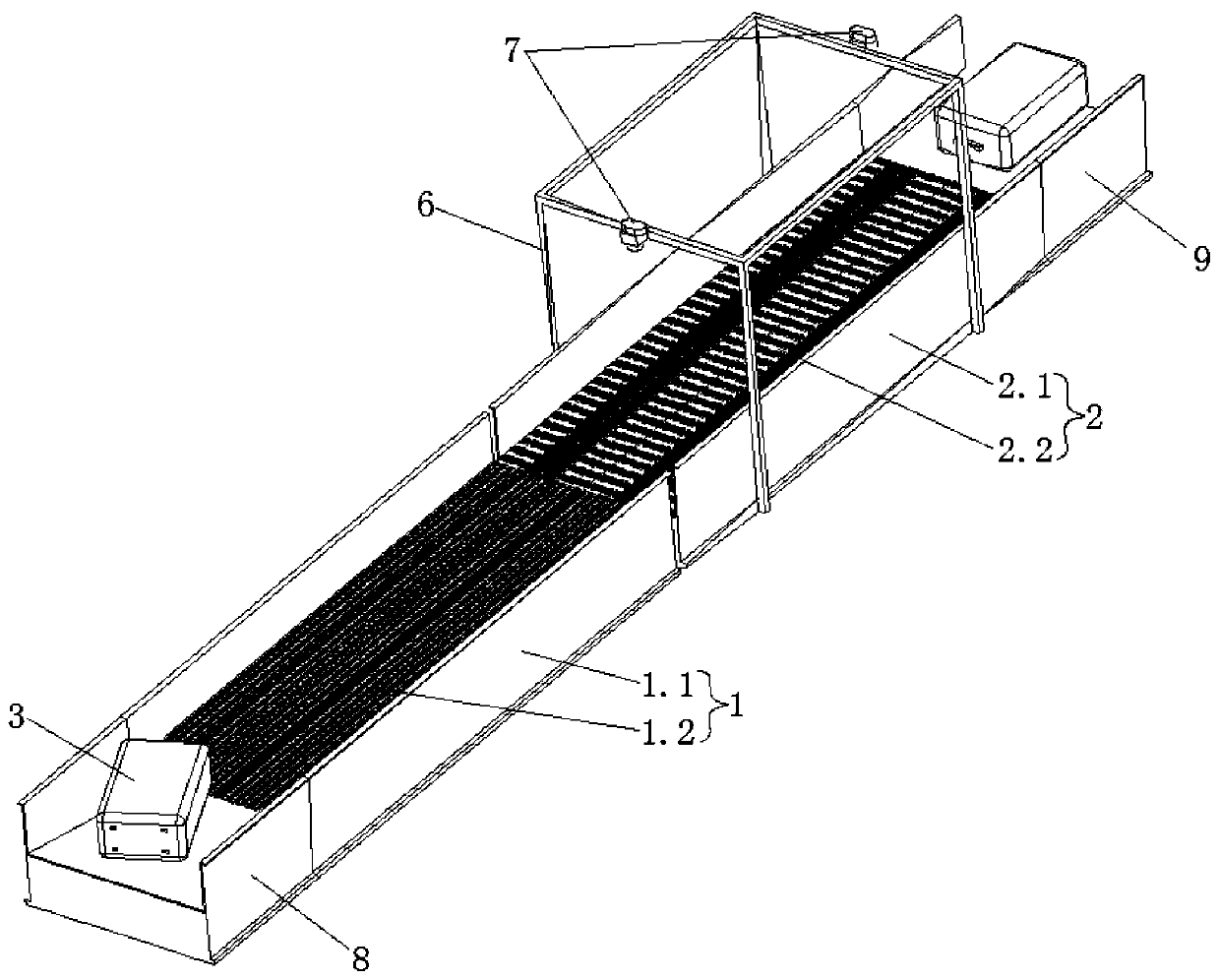

[0033] Such as Figures 1 to 3 As shown, this embodiment provides a high-speed automatic packing device for luggage, including a first adjusting conveyor 1 and a second adjusting conveyor 2 spliced together, the first adjusting conveyor 1 includes a first host 1.1, the first host 1.1 is provided with a roller conveying track 1.2, which is used to adjust the luggage 3 to the middle position of the conveying line, and the second adjustment conveyor 2 includes a second main engine 2.1, and the second main engine 2.1 is provided with two and conveying The differential conveying crawler belt 2.2 that is assembled together parallel to the line direction, and the differential conveying crawler belt 2.2 is used to straighten the luggage 3.

[0034] In this embodiment, during the process of moving forward with the luggage through the roller conveying track in the first adjustment conveyor, the luggage is first adjusted to the middle position of the conveying line, and then when the l...

Embodiment 2

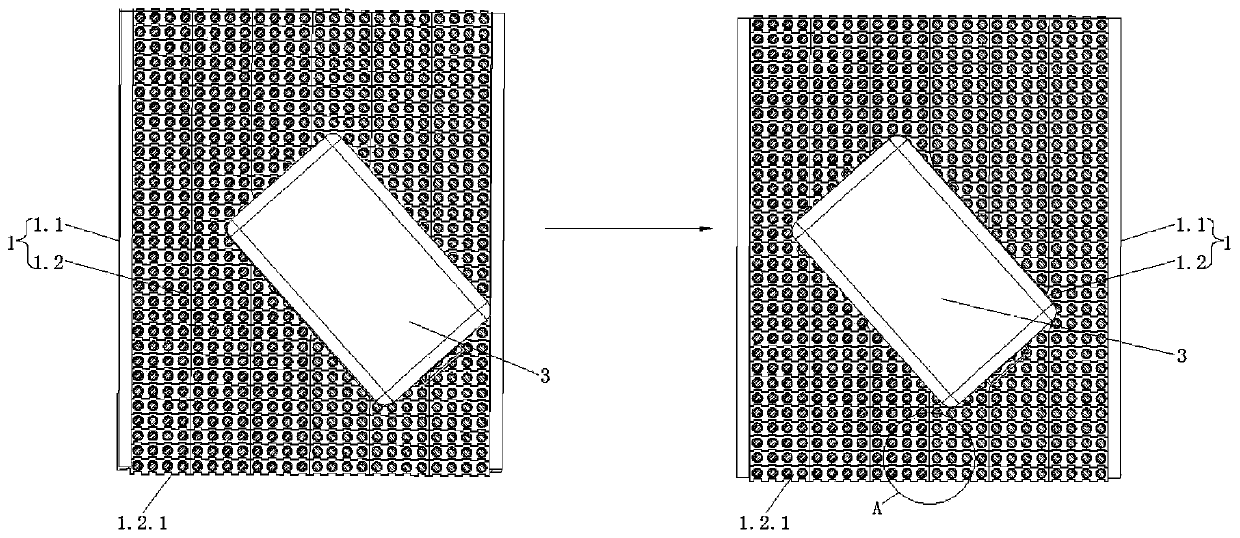

[0036] Such as Figures 1 to 7 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the roller conveying track 1.2 includes several modular conveyor belts 1.2.1 spliced together, and the modular conveyor belt 1.2.1 includes unit The belt 1.2.1.1 and the unit belt 1.2.1.1 are provided with a number of installation holes, and the rollers 1.2.1.2 for contacting with the luggage 3 are movably connected in the installation holes through the rotating shaft, and the rollers 1.2.1.2 have an included angle with the direction of the conveying line , the rollers 1.2.1.2 on both sides are symmetrically arranged with the central line of the conveying line as the symmetrical line, and the line connecting the conveying direction of the rollers 1.2.1.2 on both sides is in an inverted "V" shape.

[0037] The first main machine 1.1 is provided with a bearing plate 4 or a guide roller 5 in contact with the bottom of the roller 1.2.1.2.

[0038] In this em...

Embodiment 3

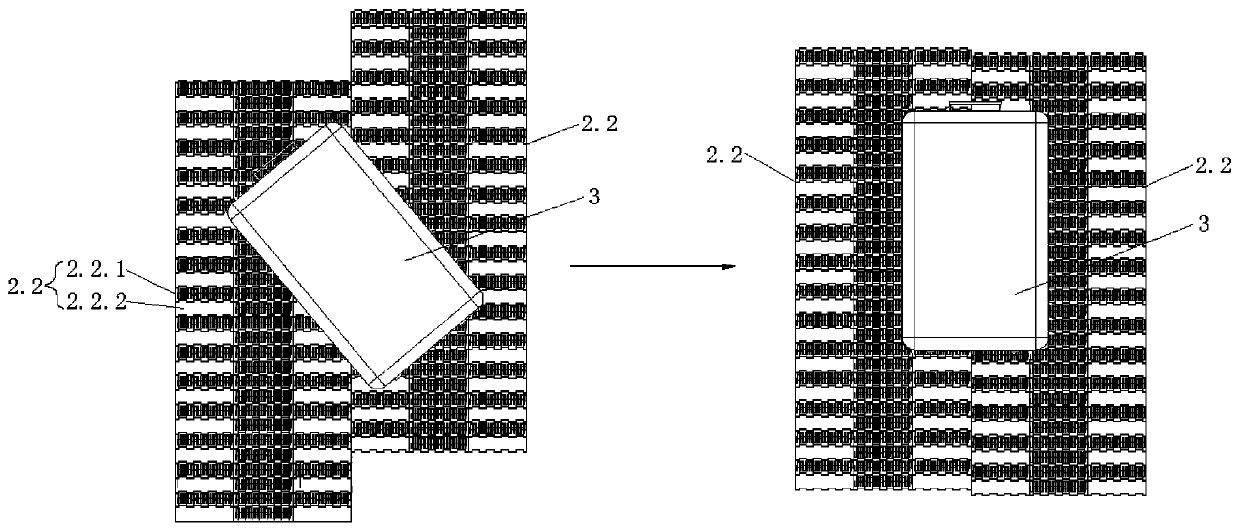

[0040] Such as image 3 and 8 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the differential conveying crawler belt 2.2 includes several friction module belts 2.2.1 and transmission module belts 2.2.2 spliced together, and the friction module belt 2.2.1 There are several anti-skid grooves 2.2.1.1 on the upper surface.

[0041] In this embodiment, the differential conveying track can be composed of several friction module belts and transmission module belts, which is easy to process. At the same time, the anti-skid groove on the friction module belt can increase the friction between the belt and the luggage, and can quickly align the luggage. , so as to accurately carry out the whole package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com