All-terrain crawler belt and belt pulley combination mechanism

A combined mechanism, all-terrain technology, used in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of easy slippage, the inability of the tracked running mechanism to adapt to various road structures, and the difficulty of walking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

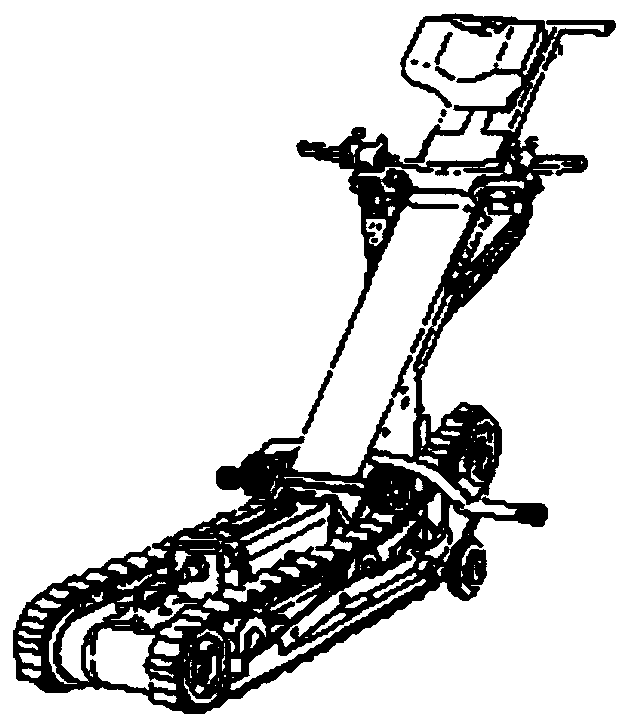

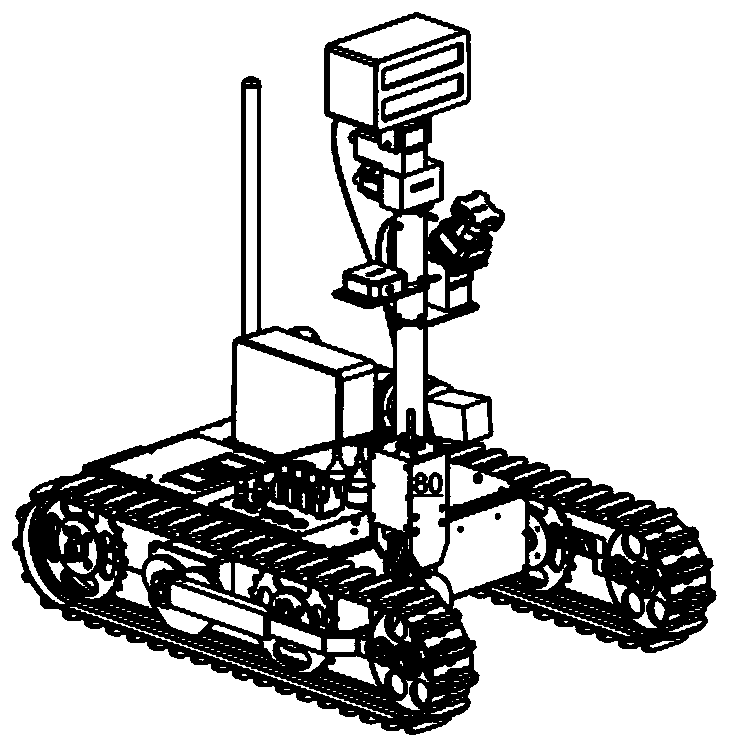

[0052] The specific structure and working principle of the all-terrain track and pulley combined mechanism provided by the present invention will be described below in conjunction with the accompanying drawings.

[0053] see Figure 2a As shown, the all-terrain track and pulley combination mechanism provided in this embodiment mainly includes the following structures:

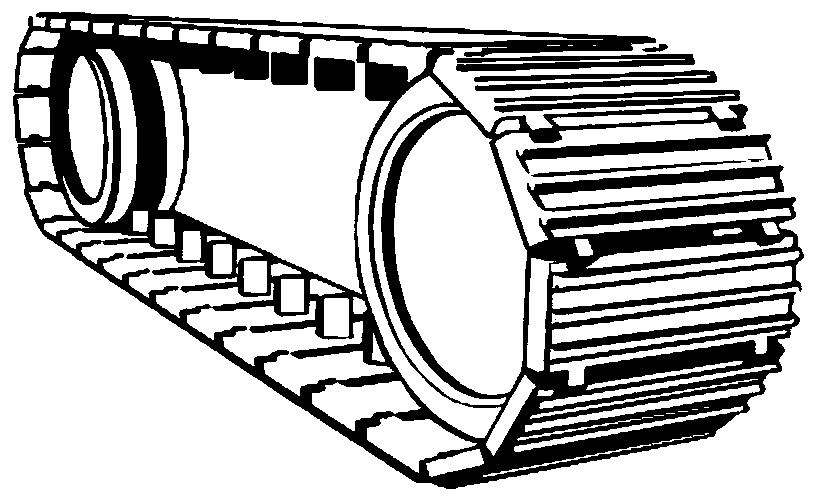

[0054] Track 1 (the material of the track can be rubber, mixed rubber or nylon, etc.), two pulleys 2 (the material of the pulley can be hard material such as metal or plastic), and the track 1 will be tightly fitted on the two pulleys 2 Above (in actual use, the number of pulleys can be selected according to actual needs). When the mechanism of the present invention is applied to a specific walking mechanism, the power of the walking mechanism will be transmitted to the track 1 through one of the pulleys 2, so that the mechanism can be used on ordinary ground, gravel roads, stairs, and mountain roads. walk. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com