An integrated device for collecting and pressing metal chips for machining

A metal scrap and machining technology, applied in metal processing equipment, metal processing mechanical parts, presses, etc., can solve the problems of low machining accuracy of machine tools, waste of water, difficult flushing, etc., to facilitate transportation and storage. , Conducive to pressing treatment and recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

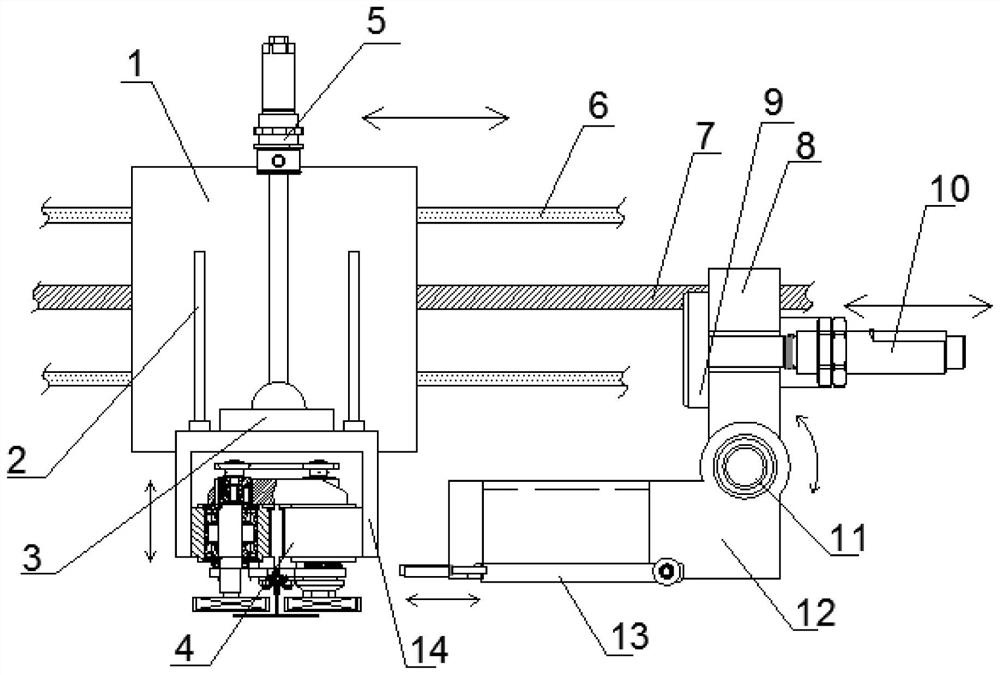

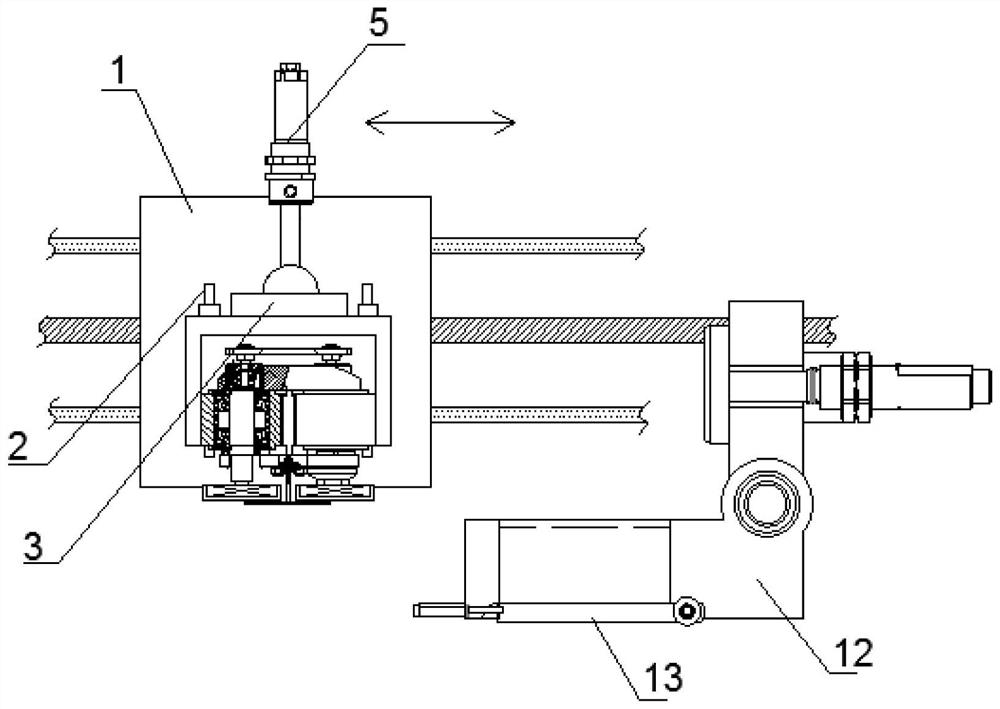

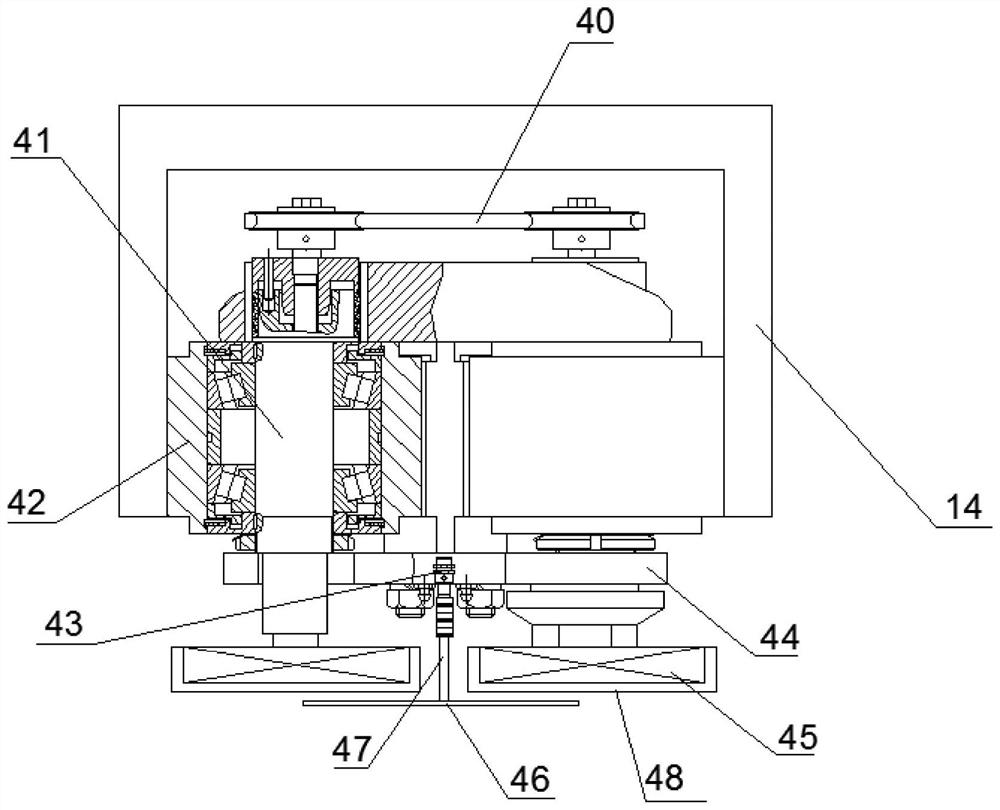

[0026] see Figure 1~4 , in an embodiment of the present invention, an integrated device for collecting and briquetting metal chips for machining, including a chip collecting mechanism 4, a two-dimensional moving mechanism and a chip briquetting mechanism, wherein the chip collecting mechanism 4 is connected to the output end of the two-dimensional moving mechanism, so that the debris collecting mechanism 4 can move along the horizontal direction and the vertical direction; The debris briquetting mechanism; the debris collection mechanism 4 can move to the first position and the second position under the drive of the two-dimensional moving mechanism; wherein, the debris collection mechanism 4 is in the first position Next, the debris collection mechanism can absorb and collect metal debris, and the debris collection mechanism is in the first position, and the lower section of the debris collection mechanism is lower than the debris pressing mechanism The lower end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com