Device and method for recovering metal from fine-grained broken product of waste circuit board

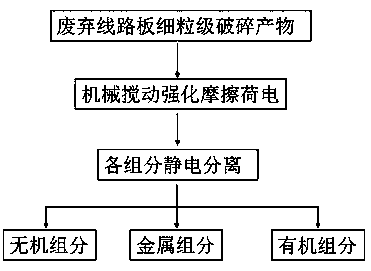

A waste circuit board, fine-grained technology, applied in chemical instruments and methods, grain processing, solid separation, etc., can solve the problems of low sorting efficiency, environmental problems, easy to produce water pollution, etc. Simple, waste-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention will be further described.

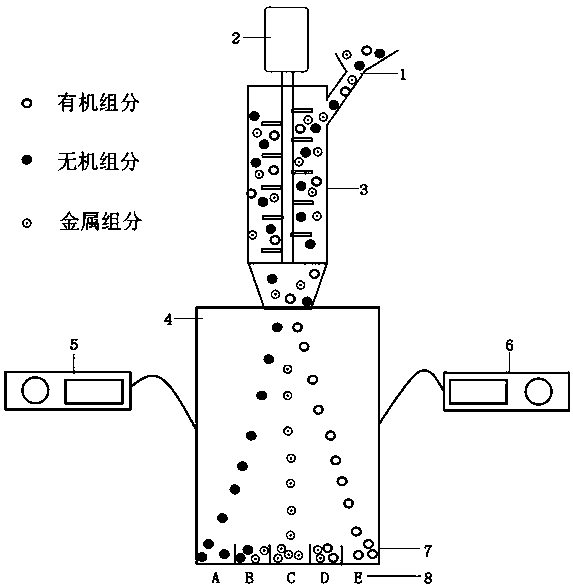

[0026] like figure 2 As shown, a device for recovering metals from the fine-grained crushed products of waste circuit boards, including a feeding device 1, an electric device 2, a friction charging device 3 and an electrostatic separation device 4, on the friction charging device 3 A feeding device 1 is provided, a stirring rod is connected to the bottom of the electric device 2, and the stirring rod extends into it from above the friction charging device 3, and the electric device 2 drives the stirring rod to rotate in the friction charging device 3, and the electric device 2 The rotating speed of the device 2 is adjustable, and the intensity of the frictional charging can be controlled by adjusting the rotating speed. The stirring rod arranged vertically has horizontal stirring teeth to strengthen the intensity of the frictional charging. The bottom of the frictional charging devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com