Chemical safety glove removing machine

A technology for removing gloves, which is applied in the field of safety glove removal devices for assisting personnel, chemical safety glove removal machines, and removal devices. Good removal effect, high adsorption force, and convenient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

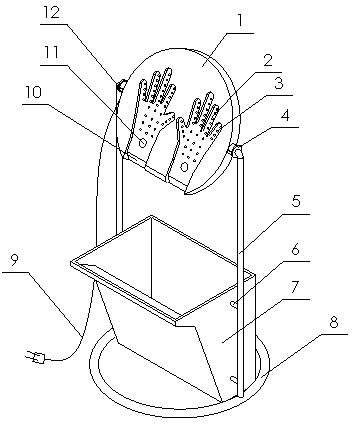

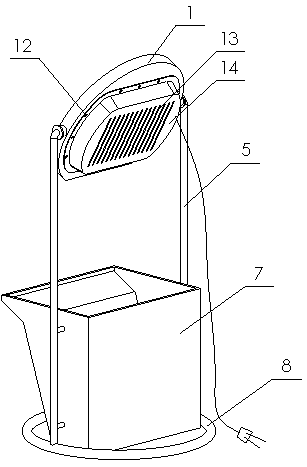

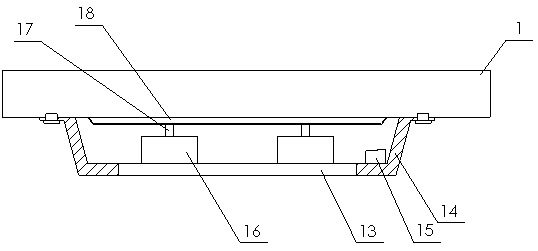

[0014] A chemical safety glove remover of the present invention is realized in the following way: a chemical safety glove remover of the present invention is composed of a main body device and a removal device, and the main body device is composed of a limit ring (4), a support rod (5), The connecting rod (6), the storage box (7) and the fixed base (8), one end of the two support rods (5) are symmetrically placed on the fixed base (8), and the other ends of the two support rods (5) First extend upwards and then bend relative to each other. The limit ring (4) is set on the support rod (5) and is close to the other end of the support rod (5). The storage box (7) is placed on the two support rods (5) between the two support rods (5) through a connecting rod (6), one side of the storage box (7) is a slope, and the cross-sectional area of the storage box (7) gradually increases from bottom to top , the bottom of the fixed base (8) is equipped with an adsorption magnet, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com