Colorimetric detection method for nitrate in explosive

A detection method and technology for explosives, applied in the field of colorimetric detection of nitrate, can solve the problems of high cost and poor portability, and achieve the effects of low cost, sensitive response and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of test reagents:

[0020] a. At room temperature, use an analytical balance to weigh out 0.015 p-aminobenzene sulfonamide, 0.005 g of N-1-naphthalene ethylenediamine hydrochloride, and 0.01 hydrazine sulfate into the flask, add 20 mL of water and stir until complete Dissolve, add 20μL of phosphoric acid, continue to stir for 10 minutes, airtight the flask, and obtain the detection reagent after 20 minutes of nitrogen flow, and package the detection reagent in the reagent bottle;

[0021] Prepare test paper;

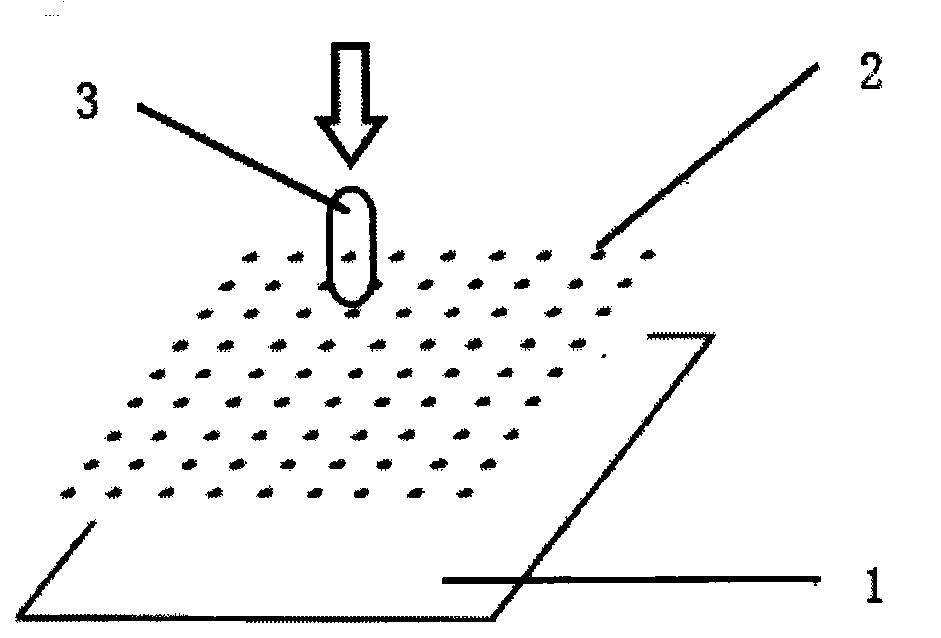

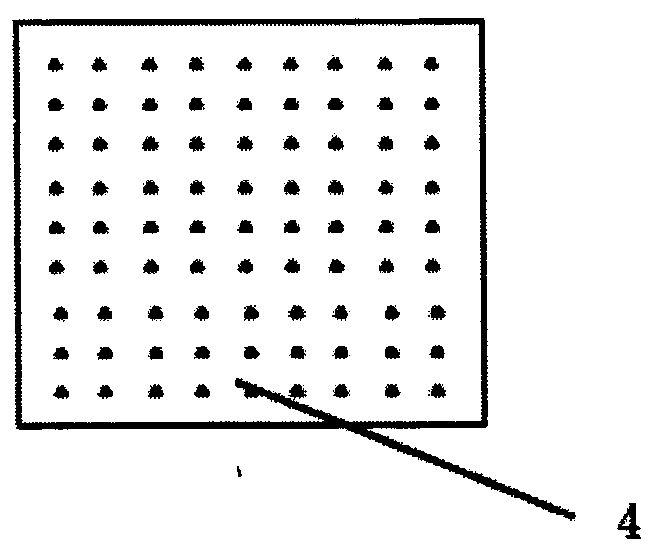

[0022] b. Apply 0.1g zinc powder 2 evenly on the filter paper 1, then drop the pressure sensitive adhesive 3, dry, and cut to obtain the test paper 4, and then put the test paper 4 into the test bag;

[0023] c. Use a cotton swab to extract the test sample from sodium nitrate (chemical reagent), wipe the sodium nitrate test sample onto the test paper 4, and drop the test reagent obtained in step a onto the test paper 4 containing the sodium nitrate test sample...

Embodiment 2

[0025] Preparation of test reagents:

[0026] a. At room temperature, use an analytical balance to weigh out 0.015 p-aminobenzene sulfonamide, 0.01 g N-1-naphthalene ethylene diamine hydrochloride, and 0.01 g hydrazine sulfate into the flask, add 20 mL of water and stir until Dissolve completely, then add 20μL phosphoric acid, continue to stir for 10 minutes, seal the flask, and obtain the detection reagent after 20 minutes of nitrogen gas. The detection reagent is packaged in the reagent bottle;

[0027] Prepare test paper;

[0028] b. Apply 0.1g zinc powder 2 evenly on the filter paper 1, then drop the pressure sensitive adhesive 3, dry, and cut to obtain the test paper 4, and then put the test paper 4 into the test bag;

[0029] c. Use a cotton swab to extract a test sample from potassium nitrate (chemical reagent), wipe the potassium nitrate test sample onto the test paper 4, and drop the test reagent obtained in step a onto the test paper 4 containing the potassium nitrate test s...

Embodiment 3

[0031] Preparation of test reagents:

[0032] a. At room temperature, use an analytical balance to weigh out 0.018 g of p-aminobenzene sulfonamide, 0.0058 g of N-1-naphthalene ethylenediamine hydrochloride, and 0.01 g of hydrazine sulfate into the flask, and add 20 mL of water to fully stir. When it is completely dissolved, add 20μL of phosphoric acid, continue to stir for 10 minutes, airtight the flask, and obtain the detection reagent after 20 minutes of nitrogen gas, and package the detection reagent in the reagent bottle;

[0033] Prepare test paper;

[0034] b. Apply 0.1g zinc powder 2 evenly on the filter paper 1, then drop the pressure sensitive adhesive 3, dry, and cut to obtain the test paper 4, and then put the test paper 4 into the test bag;

[0035] c. Use a cotton swab to extract a test sample from ammonium nitrate (chemical reagent), wipe the ammonium nitrate test sample onto the test paper 4, and drop the test reagent obtained in step a onto the test paper 4 containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com