Hollowed-out wall construction process

A construction technology and stone wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of uneven walls, low construction efficiency, and weak reinforcement of steel bars, and achieve high construction quality, reduce construction difficulty, and improve construction. The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

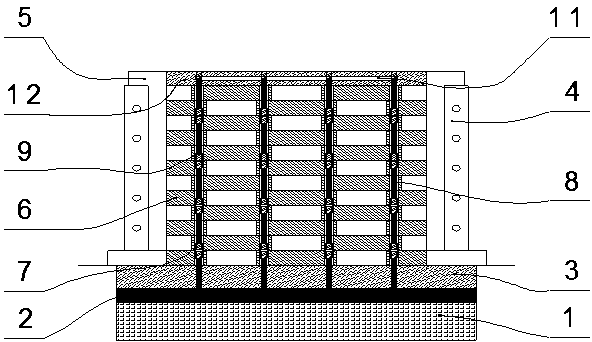

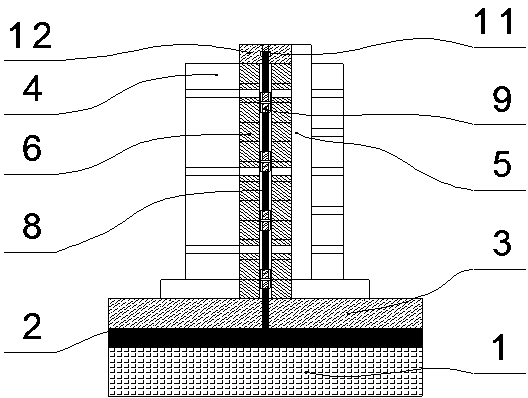

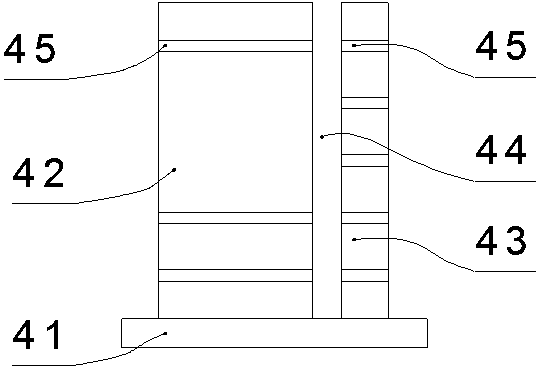

[0033] like Figure 1-7 Shown, a kind of hollow wall construction technology, it comprises the following steps:

[0034] Step 1): Preparations before construction, including surveying the terrain, selecting the location of the wall, purchasing porous stone bricks 6 and steel bars 11, preparing single-threaded steel bars 22, double-threaded steel bars 8, concrete and cement mortar, welding horizontal steel plates 10 and prefabricated Buried iron 2, installation support frame 4;

[0035] Step 2): Use a road roller or an excavator to dig out a long pit with a length not less than the length of the hollowed-out wall, a width of 0.5m, and a depth of 0.8m, and use a ramming machine to tamp the foundation, and then lay a 250mm thick stone layer 1, of which The lower floor is paved with boulders, the volume of the boulders is 0.06-0.28m^3, the upper floor is paved with crushed stones, the particle size of the crushed stones is 0.5-0.8cm, and the gaps are paved with concrete;

[0036...

Embodiment 2

[0053] like Figure 1-7 Shown, a kind of hollow wall construction technology, it comprises the following steps:

[0054] Step 1): Preparations before construction, including surveying the terrain, selecting the location of the wall, purchasing porous stone bricks 6 and steel bars 11, preparing single-threaded steel bars 22, double-threaded steel bars 8, concrete and cement mortar, welding horizontal steel plates 10 and prefabricated Buried iron 2, installation support frame 4;

[0055] Step 2): Use a road roller or an excavator to dig out a long pit with a length not less than the length of the hollow wall, a width of 1m, and a depth of 1m, and use a ramming machine to tamp the foundation, and then lay a 300mm thick stone layer 1, of which the lower layer is used Boulders are laid, the volume of the big stones is 0.06-0.28m ^ 3, the upper layer is paved with crushed stones, the particle size of the crushed stones is 0.5-0.8cm, and the gap is paved with concrete;

[0056] Ste...

Embodiment 3

[0073] like Figure 1-7 Shown, a kind of hollow wall construction technology, it comprises the following steps:

[0074] Step 1): Preparations before construction, including surveying the terrain, selecting the location of the wall, purchasing porous stone bricks 6 and steel bars 11, preparing single-threaded steel bars 22, double-threaded steel bars 8, concrete and cement mortar, welding horizontal steel plates 10 and prefabricated Buried iron 2, installation support frame 4;

[0075] Step 2): Use a road roller or excavator to dig out a long pit with a length not less than the length of the hollowed-out wall, a width of 0.7m, and a depth of 0.9m, and use a ramming machine to compact the foundation, and then lay a 280mm thick stone layer 1, of which The lower floor is paved with boulders, the volume of the boulders is 0.06-0.28m^3, the upper floor is paved with crushed stones, the particle size of the crushed stones is 0.5-0.8cm, and the gaps are paved with concrete;

[0076...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com