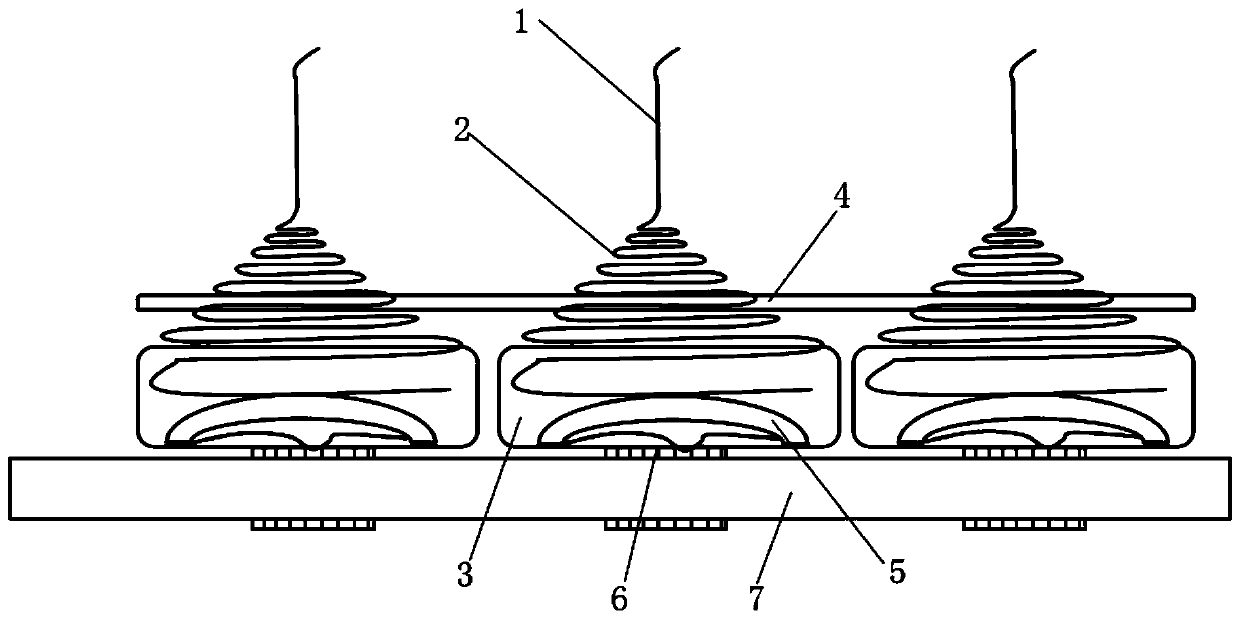

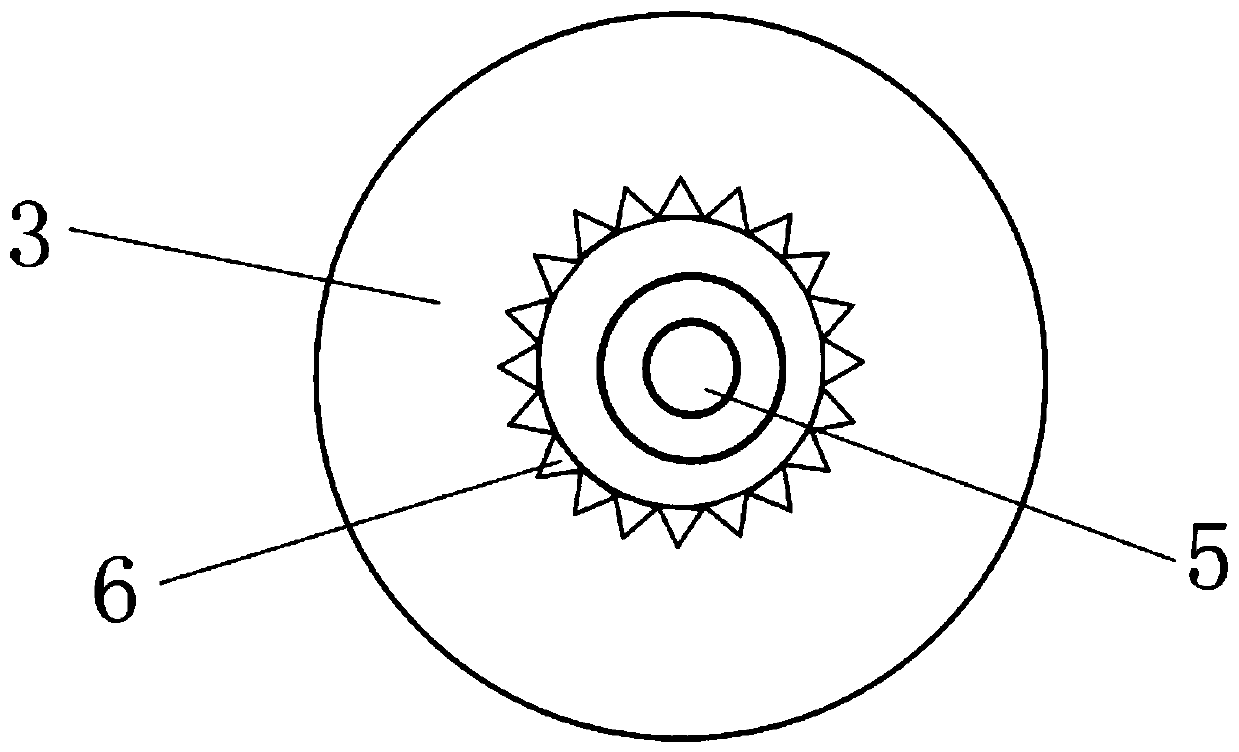

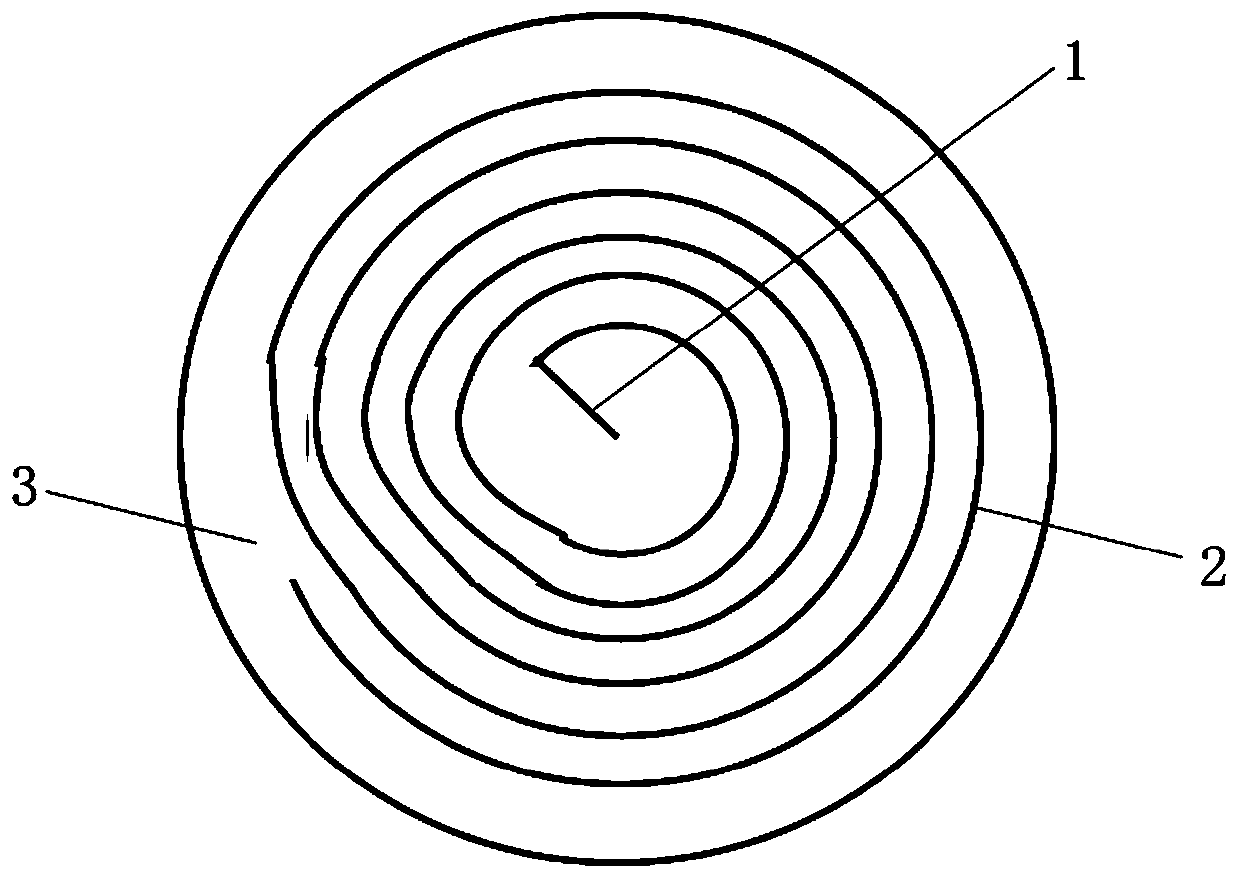

Spiral adjustable thermoelastic carding device, carding cover plate and carding machine

An adjustable and thermoelastic technology, applied in deburring devices, fiber processing, textiles and papermaking, etc., can solve problems such as poor fiber straightening parallelism, large fiber damage, and poor carding quality, and achieve improved straightening parallelism , reduce damage, improve the effect of carding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use the domestic cotton fiber raw material sample, respectively by the existing common carding machine (Jiacheng Electromechanical DSCa-01 digital sample carding machine) and the carding machine using the present invention on the market, adopt the same mechanical parameters to card, and use the same equipment and parameters for spinning, the obtained carding and yarn quality results are shown in Table 1:

[0032] Table 1 Carding results of domestic cotton fiber

[0033]

[0034] In this embodiment, the heating temperature controlled by the electrothermal ceramic sheet 5 to the comb needle 1 is 120° C., and the height of the helical spring 2 protruding from the base cloth 4 is 1 mm.

Embodiment 2

[0036] Use the domestic polyester-cotton 50 / 50 blended fiber raw material sample, through the existing common carding machine (Jiacheng Electromechanical DSCa-01 digital sample carding machine) and the carding machine of the present invention respectively on the market, adopt the same mechanical parameters to card , and spinning with the same equipment and parameters, the obtained carding and yarn quality results are shown in Table 2:

[0037] Table 2 Carding results of domestic polyester-cotton 50 / 50 blended fibers

[0038]

[0039] In this embodiment, the heating temperature of the electrothermal ceramic sheet 5 to the comb needle 1 is 150° C., and the height of the helical spring 2 protruding from the base cloth 4 is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com