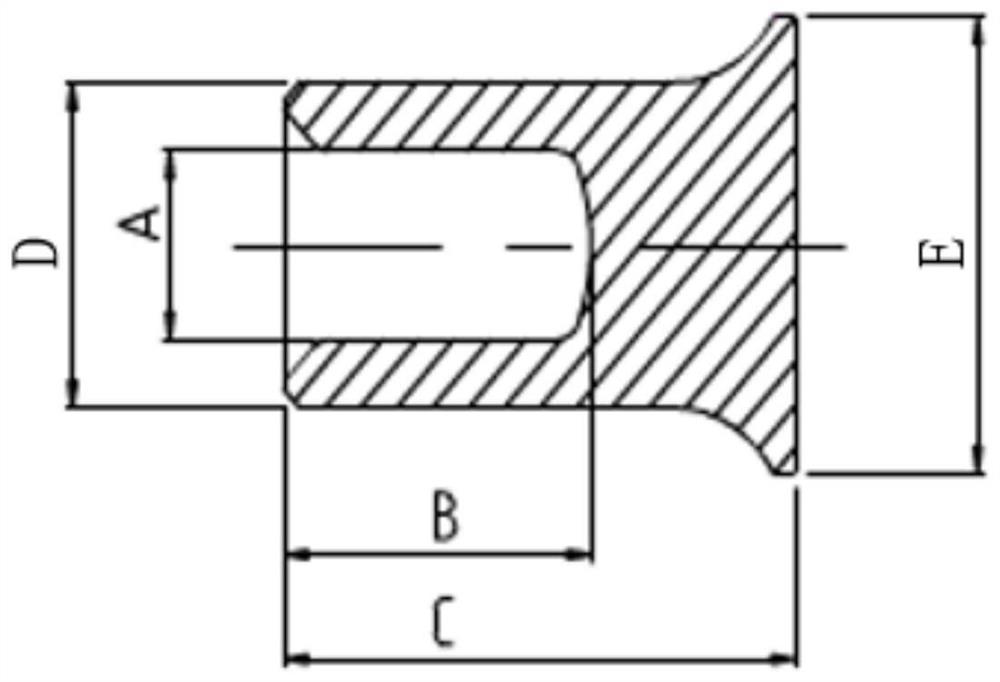

A kind of anti-fatigue rivet and its manufacturing method

A fatigue-resistant, rivet technology, applied in rivets and other directions, can solve the problems of low safety factor of rivet connection, achieve the effect of improving hearing comfort, reducing vibration noise, and reducing fatigue loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

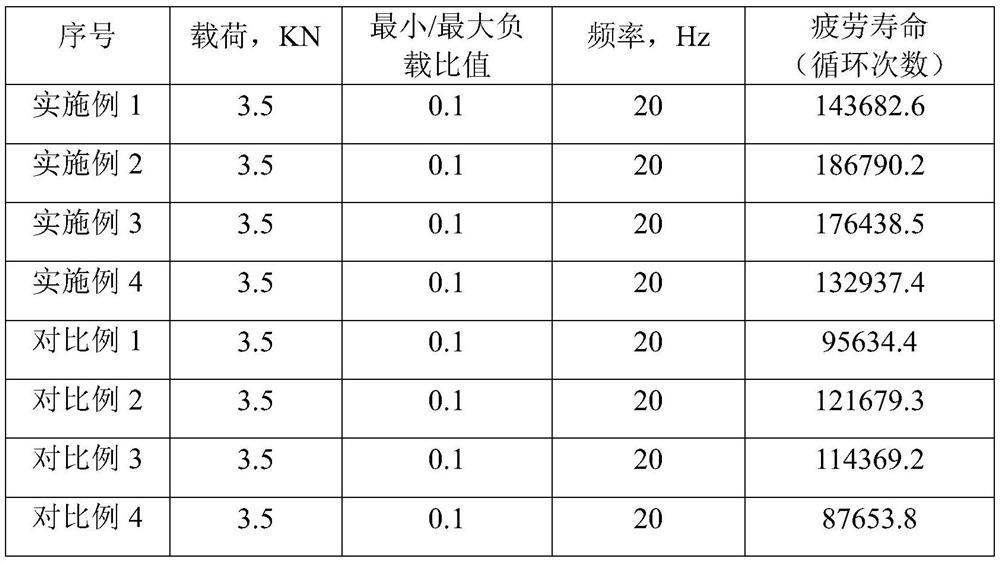

Examples

Embodiment 1

[0041] S1a: Prepare graphene dispersion: add 10 g of graphene powder into 1 L of absolute ethanol, and obtain a graphene dispersion with a concentration of 1.0% by ultrasonic dispersion;

[0042]S1b: Preparation of composite powder: 1990g of copper metal powder was added to the graphene dispersion, then mixed and ball-milled for 8 hours under the protection of argon, the ball milling speed was 800rpm / min, and then vacuum-dried to obtain a composite powder, graphene accounted for the 0.5% by weight of the total weight of the composite powder, the purity of the copper powder is ≥99.9% by weight, the mesh number is 500 mesh, and the particle size is 25 μm; the obtained composite powder is prepared by an ion sintering method to obtain a copper-graphene prefabricated ingot;

[0043] S2: Preparation of alloy ingots: Weigh raw materials by weight percentage, relative to 100 parts by weight of vibration-damping alloy, weigh 50 parts by weight of iron, 30 parts by weight of aluminum, 13...

Embodiment 2

[0046] S1a: preparation of graphene dispersion: add 10 g of graphene powder into 1.5 L of absolute ethanol, and obtain a graphene dispersion with a concentration of 0.67% by ultrasonic dispersion;

[0047] S1b: Preparation of composite powder: 2490g of aluminum metal powder was added to the graphene dispersion, then mixed and ball-milled for 8 hours under the protection of argon, the ball milling speed was 800rpm / min, and then vacuum-dried to obtain a composite powder, graphene accounted for the 0.4% by weight of the total weight of the composite powder, the purity of the aluminum powder is ≥99.9% by weight, the mesh number is 600 mesh, and the particle size is 21 μm; the obtained composite powder is prepared by an ion sintering method to obtain an aluminum-graphene prefabricated ingot;

[0048] S2: Preparation of alloy ingot: Weigh raw materials by weight percentage, relative to 100 parts by weight of vibration-damping alloy, weigh 45 parts by weight of iron, 30 parts by weigh...

Embodiment 3

[0051] S1a: Prepare graphene dispersion: add 12g of graphene powder into 4.0L of absolute ethanol, and obtain a graphene dispersion with a concentration of 0.3% by ultrasonic dispersion;

[0052] S1b: Preparation of composite powder: 2488g of aluminum metal powder was added to the graphene dispersion, then mixed and ball-milled for 8 hours under the protection of argon, the ball milling speed was 800rpm / min, and then vacuum-dried to obtain a composite powder, graphene accounted for the 0.48% by weight of the total weight of the composite powder, the purity of the aluminum powder is ≥99.9% by weight, the mesh number is 500 mesh, and the particle size is 25 μm; the obtained composite powder is prepared by an ion sintering method to obtain an aluminum-graphene prefabricated ingot;

[0053] S2: Preparation of alloy ingot: Weigh raw materials by weight percentage, relative to 100 parts by weight of vibration-damping alloy, weigh 42 parts by weight of iron, 33 parts by weight of alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com