Self-produced fuel gas combustion linkage type pyrolysis and gasification device

A technology of pyrolysis gasification and gas combustion, which is applied in the direction of gasification device feeding tool, gasification process, and production of combustible gas, which can solve the problems of high energy consumption, poor control of combustion reaction, and influence on the precipitation of combustible gas. , to achieve the effect of ensuring the precipitation effect and reducing the difficulty of cooling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

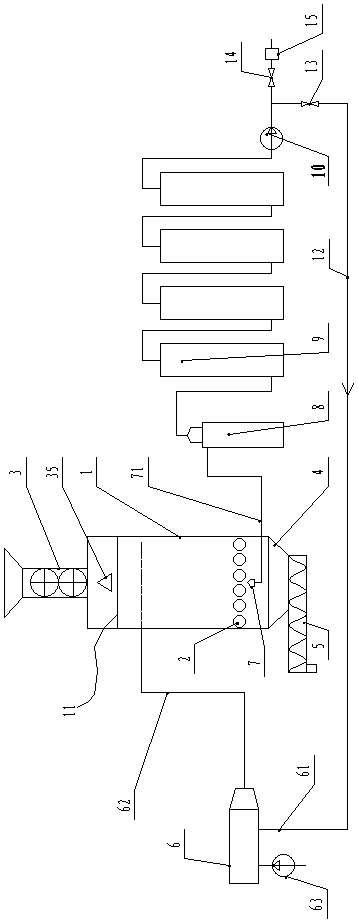

[0047] Such as figure 1 As shown, an oxygen-free medium-temperature downdraft pyrolysis device of the present invention includes a pyrolysis furnace 1, a fire grate 2 is arranged in the pyrolysis furnace 1, and a feed inlet is provided at the pyrolysis furnace 1 above the fire grate 2 , the feed inlet is equipped with a closed feeder 3, the pyrolysis furnace 1 under the grate 2 forms a slag bin 4, the slag bin is provided with a discharge port downward, and a closed feeder is provided at the discharge port. Discharger 5.

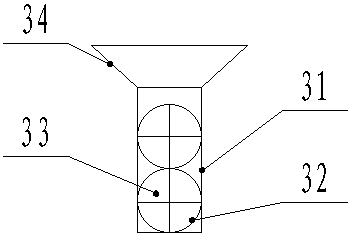

[0048] Such as figure 2 As shown, in the present embodiment, the closed feeder 3 includes a feed cylinder 31 connected to the feed port, the cross section of the feed cylinder 31 is a rectangular structure, and two horizontal cylinders are arranged tangentially up and down in the feed cylinder 31. Arranged feed roller 32, the feed roller 32 is matched and sealed with the feed cylinder 31, the feed roller 31 is arranged with an axially extending trough 33 ...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, the present embodiment adopts an updraft structure, the flue gas delivery pipe 62 is located below the grate 2 , and the end of the flue gas delivery pipe 62 points upward to the fire grate 2 and is connected to a medium temperature heater 64 .

[0067] In this embodiment, the medium-temperature heater 64 is a cone structure connected to the end of the flue gas conveying pipe, and the tip of the cone also points upward to the grate, and the side wall of the cone is provided with an exhaust port, so that the pyrolysis furnace 1 The uniform supply of oxygen-free medium-temperature flue gas in the pyrolysis furnace ensures the uniformity of the medium-temperature temperature field formed in the pyrolysis furnace 1.

[0068] The combustible gas collector 7 is provided with a combustible gas collecting port adjacent to the top of the pyrolysis furnace above the fire grate. In this embodimen...

Embodiment 3

[0070] The difference between this embodiment and Embodiment 1 is that: Image 6 As shown, this embodiment adopts a side suction structure, the flue gas delivery pipe 62 is located below the grate 2 , and the end of the flue gas delivery pipe 62 points upward to the fire grate 2 and is connected to a medium temperature heater 64 .

[0071] In this embodiment, the medium-temperature heater 64 is a cone structure connected to the end of the flue gas conveying pipe, and the tip of the cone also points upward to the grate, and the side wall of the cone is provided with an exhaust port, so that the pyrolysis furnace 1 The uniform supply of oxygen-free medium-temperature flue gas in the pyrolysis furnace ensures the uniformity of the medium-temperature temperature field formed in the pyrolysis furnace 1.

[0072] The combustible gas collector 7 is provided with a combustible gas collecting mechanism at the side wall above the fire grate. The combustible gas collection mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com