Side suction type anaerobic medium-temperature pyrolysis furnace

A pyrolysis furnace and side-suction technology, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of affecting the precipitation of combustible gases, poor control of combustion reactions, and high energy consumption, etc., to reduce the cooling process Difficulty, avoiding the risk of explosion, and ensuring the effect of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

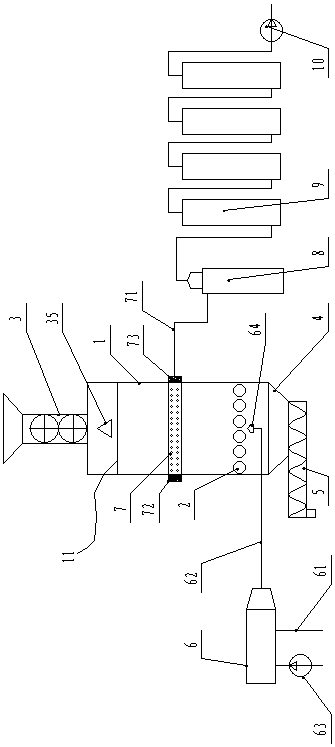

[0042] Such as figure 1 As shown, an oxygen-free mid-temperature lower suction pyrolysis device of the present invention includes a pyrolysis furnace 1, a grate 2 is provided in the pyrolysis furnace 1, and a feed port is provided at the pyrolysis furnace 1 above the grate 2 , The feed inlet is equipped with a closed feeder 3, the pyrolysis furnace 1 below the grate 2 is formed with a slag bin 4, the slag bin is provided with a discharge port downward, and the discharge port is equipped with a closed type Discharger 5.

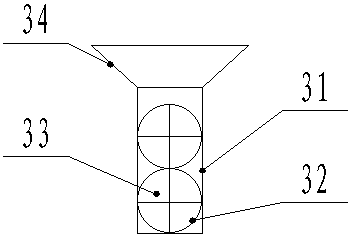

[0043] Such as figure 2 As shown, in this embodiment, the closed feeder 3 includes a feeding barrel 31 connected with a feeding port. The cross section of the feeding barrel 31 is a rectangular structure, and the upper and lower sides of the feeding barrel 31 are provided with two horizontal The feed roller 32 is arranged, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com