Special sponge for odorless food packaging

A food packaging and sponge technology, applied in the field of sponges, can solve the problems of harming health and easy residual odor, and achieve the effects of low chemical residues, convenient preparation, and elimination of chemical residues such as formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

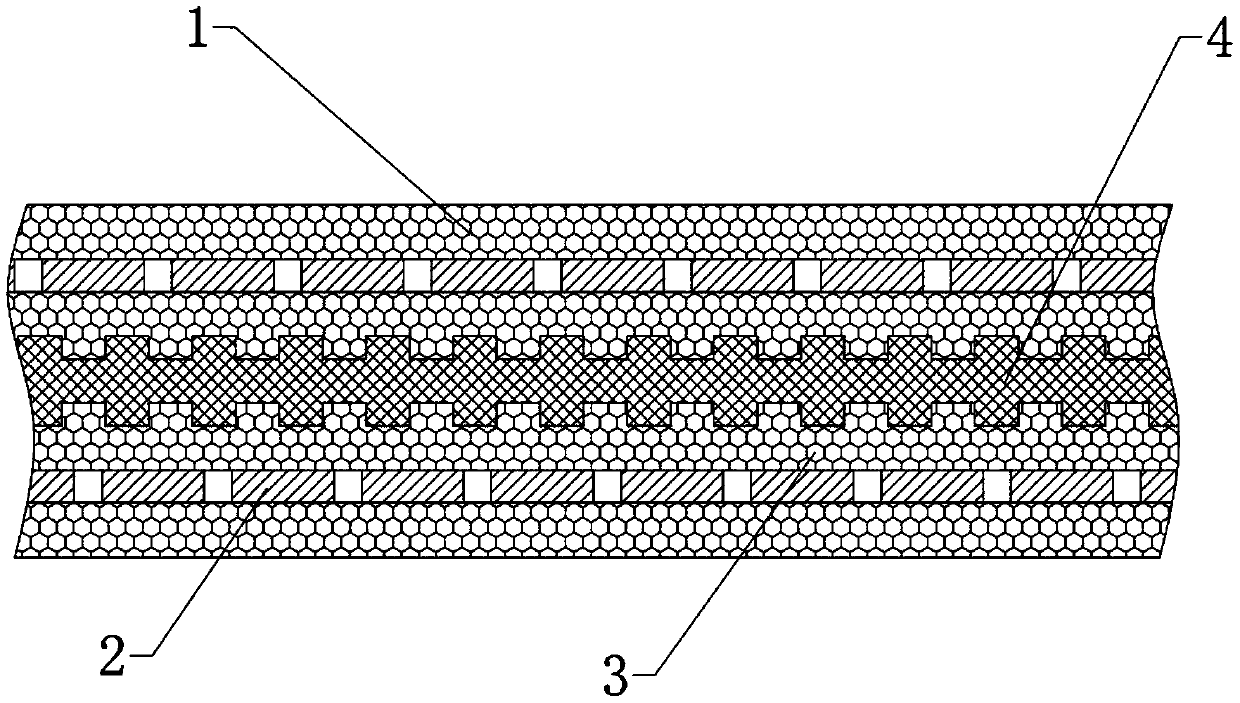

Image

Examples

Embodiment

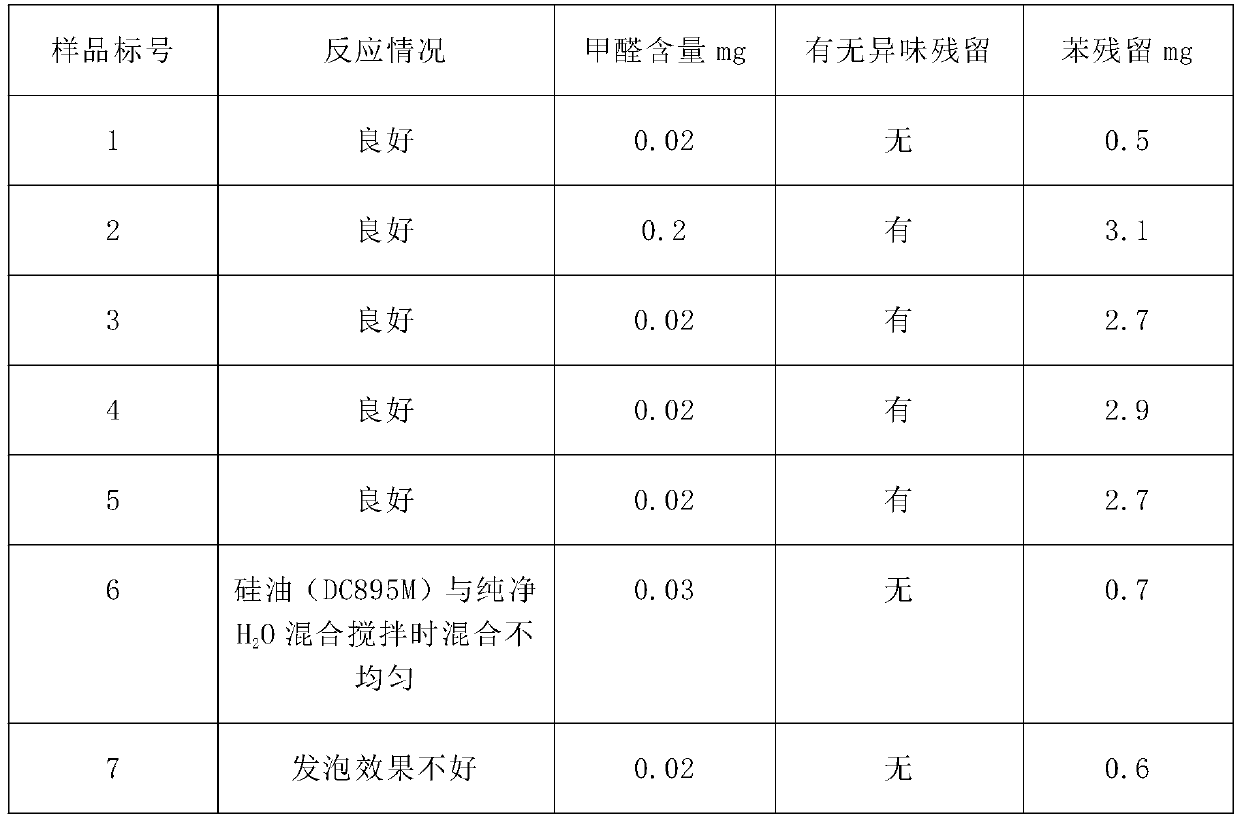

[0026] Embodiment: According to the different raw materials used and the different proportions, 7 groups of comparative components were weighed respectively:

[0027] Comparison group 1: 100 parts of high-purity polyether polyol, 40 parts of TDI, 38 parts of methane, pure H 2 O8.5 parts, silicone oil (DC895M) 14 parts, amine (CS20) 2.8 parts, tin (T11) 1.6 parts;

[0028] Comparative group 2: 100 parts of ordinary polyether polyol, 40 parts of TDI, 38 parts of methane, H 2 O8.5 parts, silicone oil (M580) 14 parts, amine (A33) 2.8 parts, tin (T9) 1.6 parts;

[0029] Comparative group 3: 100 parts of high-purity polyether polyol, 40 parts of TDI, 38 parts of methane, pure H 2 O8.5 parts, silicone oil (DC895M) 14 parts, amine (A33) 2.8 parts, tin (T11) 1.6 parts;

[0030] Comparative group 4: 100 parts of high-purity polyether polyol, 40 parts of TDI, 38 parts of methane, H 2 O8.5 parts, silicone oil (DC895M) 14 parts, amine (CS20) 2.8 parts, tin (T11) 1.6 parts;

[0031] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com