Forming method of carbon nanotube film/composite material and lightning protection structure

A technology of carbon nanotube film and composite materials, which is applied in the field of lightning protection of aircraft composite materials, can solve problems such as complex procedures, poor fusion of composite materials, and heavy weight of conductive functional layers for lightning protection, and achieve simplified processes, good interface fusion, and Guaranteed lightning protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

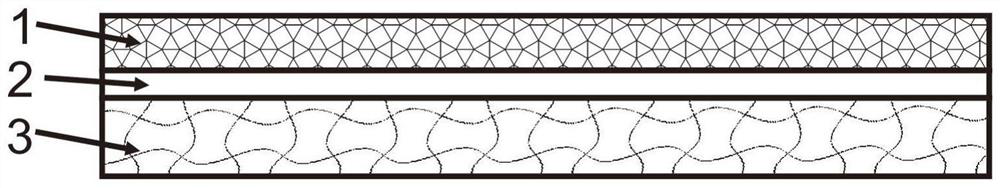

[0058] This embodiment proposes a carbon nanotube film / composite material lightning protection structure, such as figure 1 and figure 2 As shown, the lightning protection structure includes:

[0059] Carbon nanotube films used as conductive layers;

[0060] Composite materials, including fibers and resins filled with fibers;

[0061] An adhesive film for electrical insulation between the composite material and the carbon nanotube film;

[0062] The carbon nanotube film, adhesive film and composite material are arranged in sequence.

[0063] The fiber is a dry fiber, and the material is not limited, and may be carbon fiber or glass fiber.

[0064] The carbon nanotube film is a continuous high-conductivity ultra-light carbon nanotube film.

[0065] The thickness of the carbon nanotube film is not less than 15 μm, and the thickness is adjustable.

[0066] The surface density of the carbon nanotube film is not more than 10g / m 2 .

[0067] The carbon nanotube thin film is ...

Embodiment 2

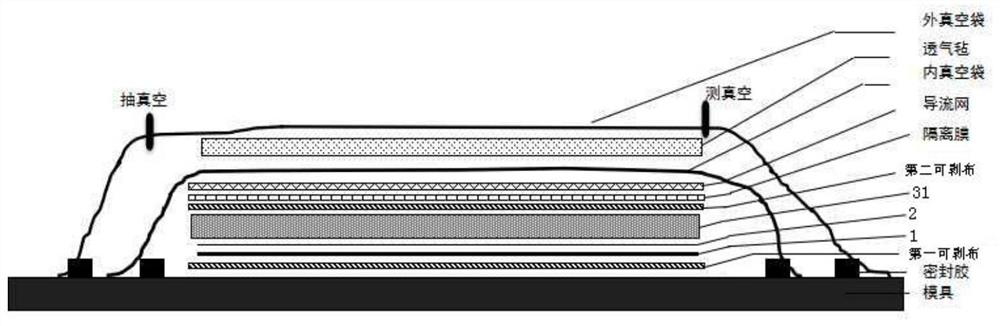

[0073] This embodiment provides a forming method for preparing the carbon nanotube film / composite material lightning protection structure in Example 1. The forming method is based on a highly conductive ultra-light carbon nanotube film for multi-scale nanocomposite lightning protection The structural design of the layer; the molding method adopts the low-cost liquid molding one-step method to obtain the ultra-light carbon nanotube film / composite material lightning protection structure as a whole; solves the problem of the fusion of the existing composite material lightning protection conductive functional layer with a large weight and the body composite material In order to solve the problems of poor performance and complicated process, the multi-scale ultra-light carbon nanotube composite lightning protection structure can be integrally formed in one step.

[0074] The multi-scale means that the lightning protection structure has a structure of nanometer / micrometer / millimeter / ...

Embodiment 3

[0089] This embodiment provides a molding method for preparing the carbon nanotube film / composite material lightning protection structure in Example 1. When the composite material is a prepreg, the carbon nanotube film / composite material is prepared by using an autoclave. The lightning protection structure of the material; specifically: the carbon nanotube film, the adhesive film and the prepreg are placed in sequence, and placed in an autoclave for curing to obtain the carbon nanotube film / composite material lightning protection structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com