Linear capacitor welding machine

A technology of capacitors and welding machines, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as low efficiency, complicated welding process, and poor product consistency, and achieve the effect of ensuring high precision and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in conjunction with the following examples.

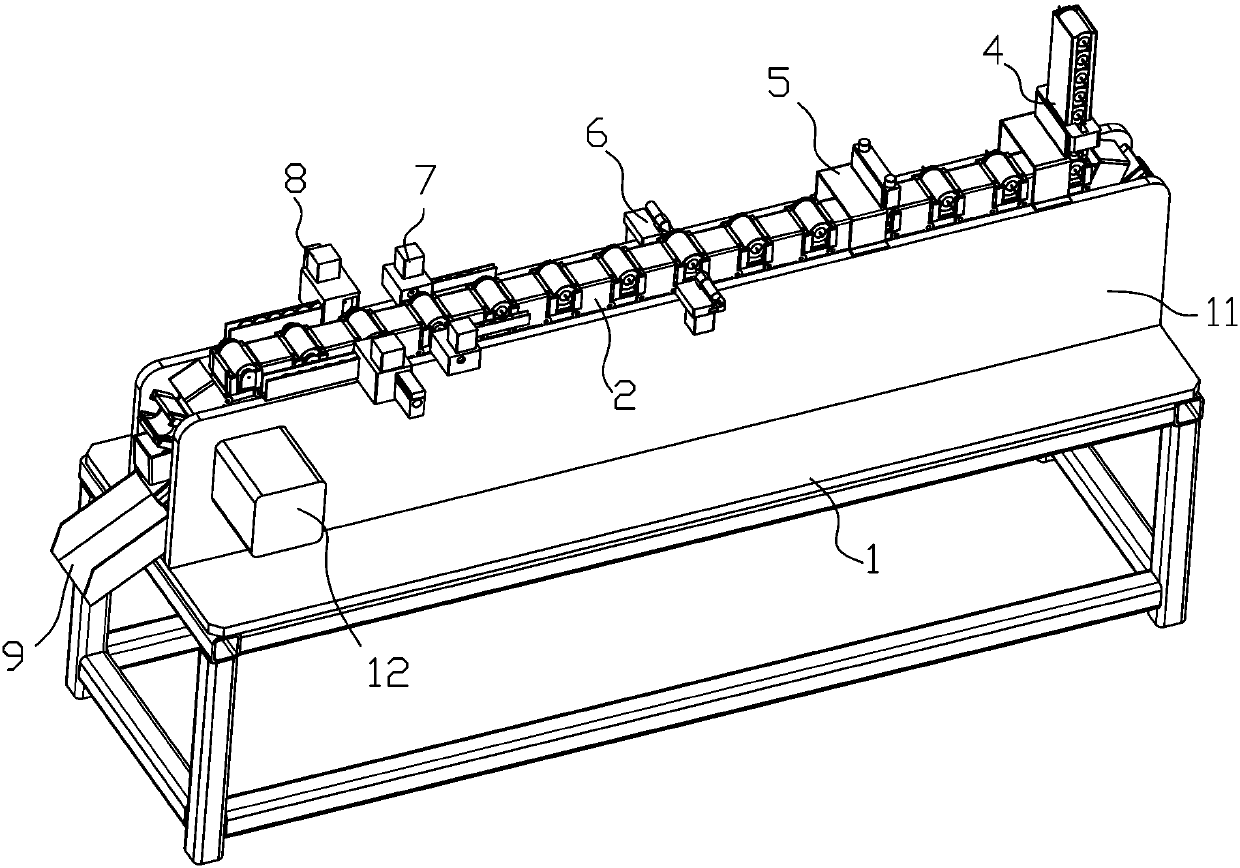

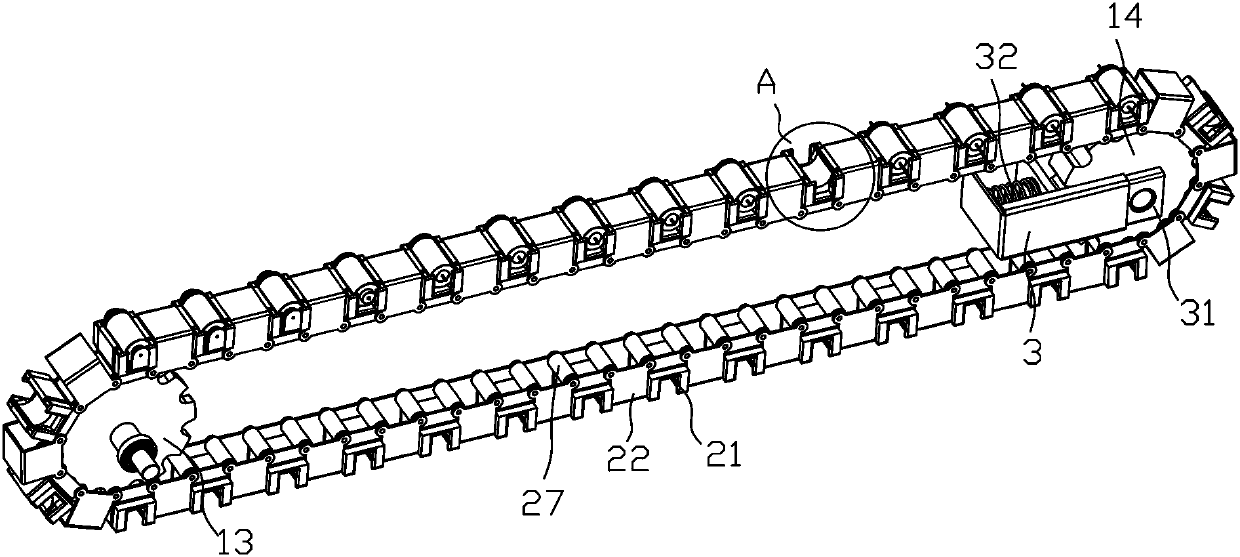

[0030] Depend on Figure 1 to Figure 11 It can be seen that a linear capacitor welding machine described in this embodiment includes a frame 1, a vertical plate 11 disposed on the frame 1, a driving element 12 disposed on the vertical plate 11, and is connected to the output end of the driving element 12. The driving sprocket 13, the driven sprocket 14 linked with the driving sprocket 13, the chain 2 set between the driving sprocket 13 and the driven sprocket 14 and the vertical plate 11 for making the chain 2 tight tensioning mechanism;

[0031] The vertical plate 11 is sequentially provided with a capacitor feeding mechanism 4, a laser tangent mechanism 5, a ball welding mechanism 6, an insulating pad sleeve mechanism 7, an electrode sheet feeding and welding mechanism 8, and a discharge mechanism in the moving direction of the chain 2;

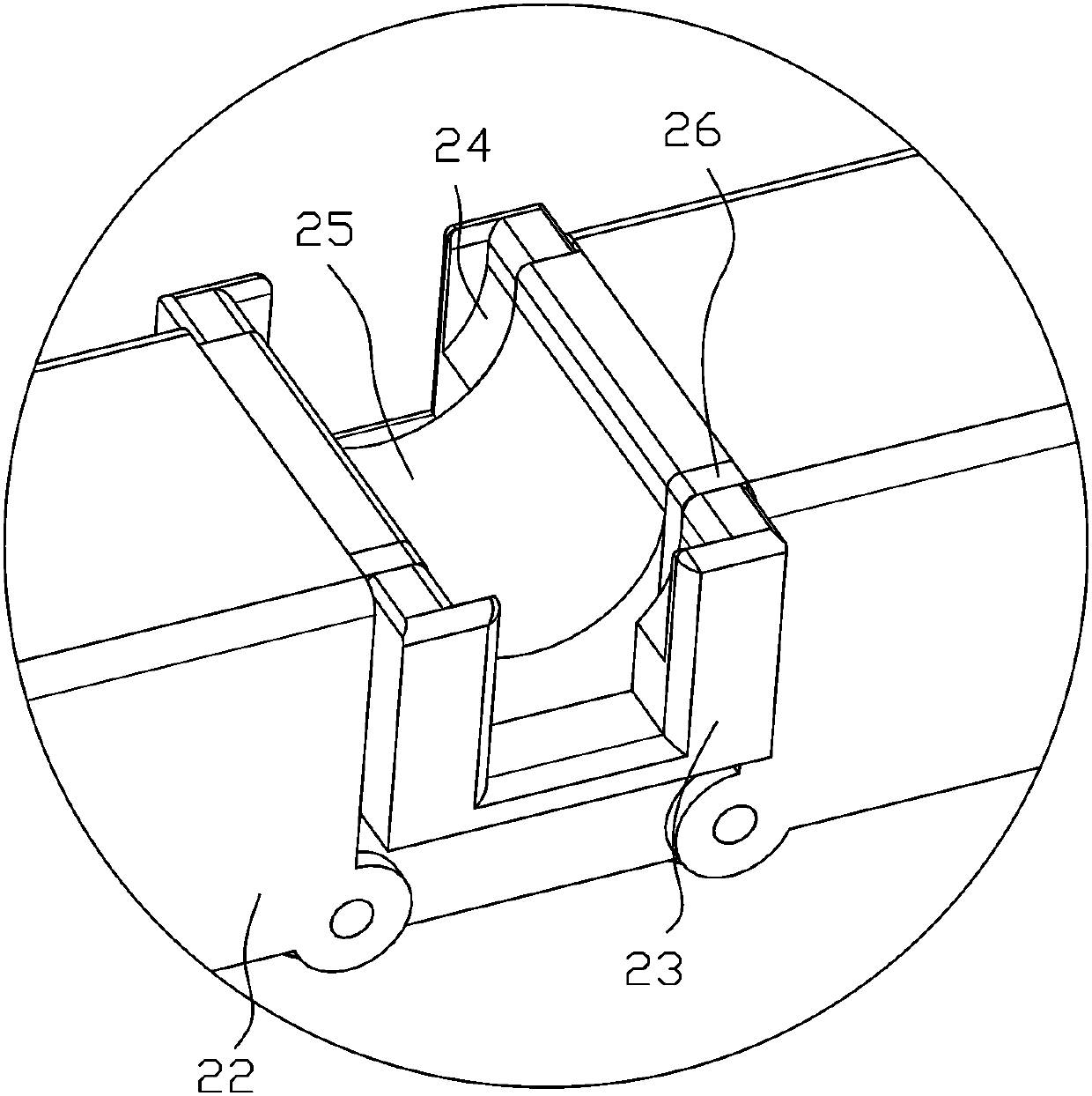

[0032] The chain 2 includes a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com