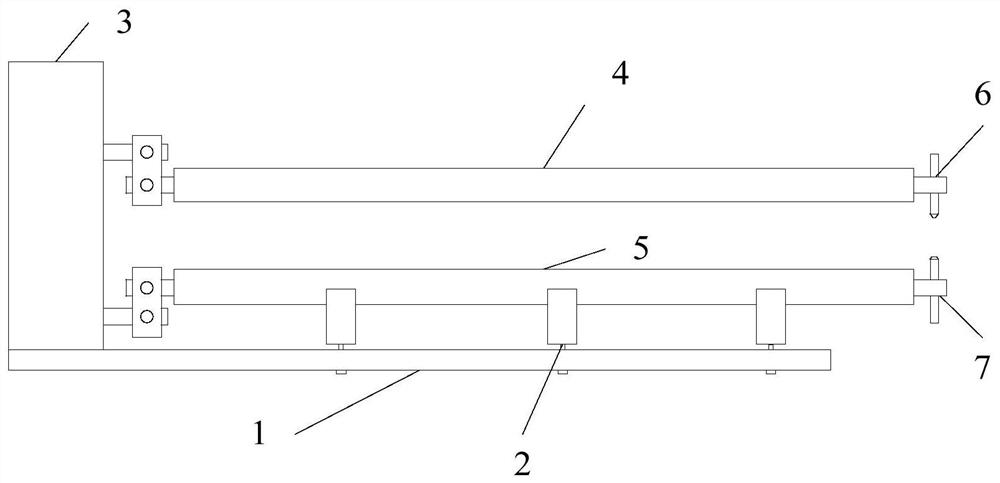

Resistance welding cantilever electrode tool and welding method for ultra-thin copper layer of large thin-walled structure

A thin-wall structure, ultra-thin copper layer technology, applied in resistance electrode bases, resistance welding equipment, manufacturing tools, etc., can solve the problems that electrodes cannot be welded at fixed points, electrode end faces are not parallel, and cantilever stiffness deformation, etc., to reduce relative displacement. Quantity, ensure welding quality, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] This embodiment provides the resistance welding method applying the resistance welding cantilever electrode tool of the present invention, comprising the following steps:

[0044] In the first step, the distance between the upper electrode and the lower electrode is controlled to be 15cm by a resistance spot welding machine.

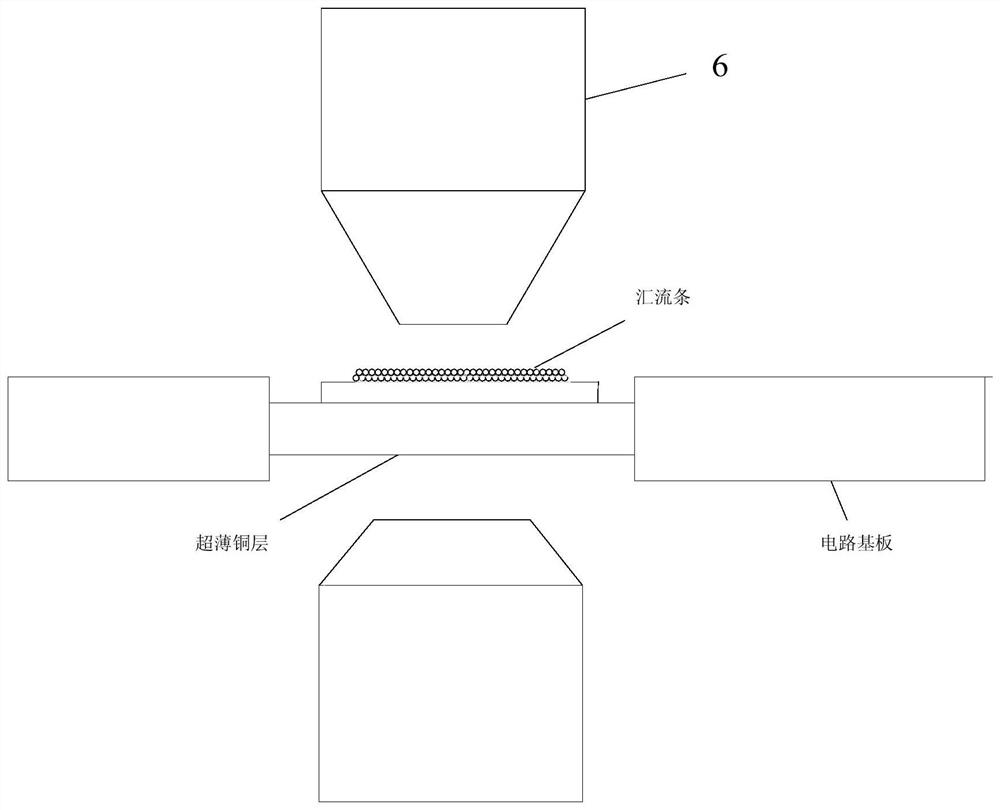

[0045] In the second step, control the upper cantilever and the lower cantilever to go deep into the depth of the large thin-walled structural part by 50cm through the resistance spot welding machine, so as to ensure that the lower electrode is located on the lower surface of the ultra-thin copper layer of the large thin-walled structure, and the upper electrode is located on the confluence of the large thin-walled structure. top surface of the strip.

[0046] The third step is to raise the welding machine or move the parts to be welded so that the lower electrode is aligned with the welding part. When the ultra-thin copper layer is observed to bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com