Airflow type dust prevention device and dust prevention method used for tipping paper printing production line

A technology of dust-proof device and tipping paper, which is applied in the direction of cleaning method, combination device and separation method using gas flow, can solve the problems of limited electrostatic dust removal effect, poor overall effect of electrostatic dust removal, and high cost of production line, and achieves cleaning and The drying process is convenient, the on-site dust-proof treatment can be realized, and the effect of avoiding large shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

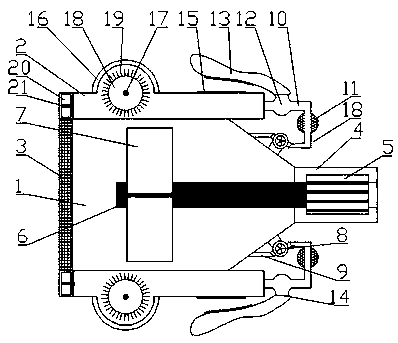

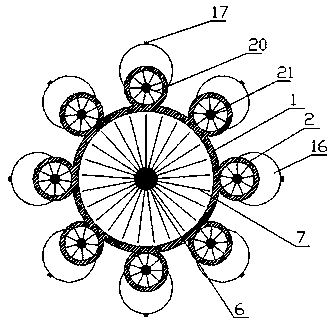

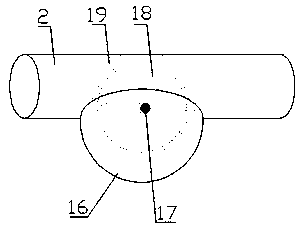

[0031] Reference Figure 1-3 , The air-flow type dustproof device for the tipping paper printing production line, including a suction cylinder 1 and a blowing cylinder 2 annularly distributed around the suction cylinder 1, characterized in that the suction cylinder 1 and the blowing cylinder 2 are arranged in parallel, and the suction cylinder body 1 and the blowing cylinder body 2 are integrally formed, the front end outlet of the suction cylinder body 1 and the front end outlet of the blowing cylinder body 2 are arranged flush; the front end outlet of the suction cylinder body 1 is provided with a filter Net 3, the tail of the suction cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com