Modification method capable of improving permeation flux of polyamide composite membranes

A technology of permeation flux and polyamide, which is applied in the field of modification to improve the permeation flux of polyamide composite membranes, can solve the problems of pollution, reduce the interception performance, and the water quality of the produced water does not meet the requirements, and achieves accelerated mass transfer and application scope. Wide, improve the effect of membrane separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

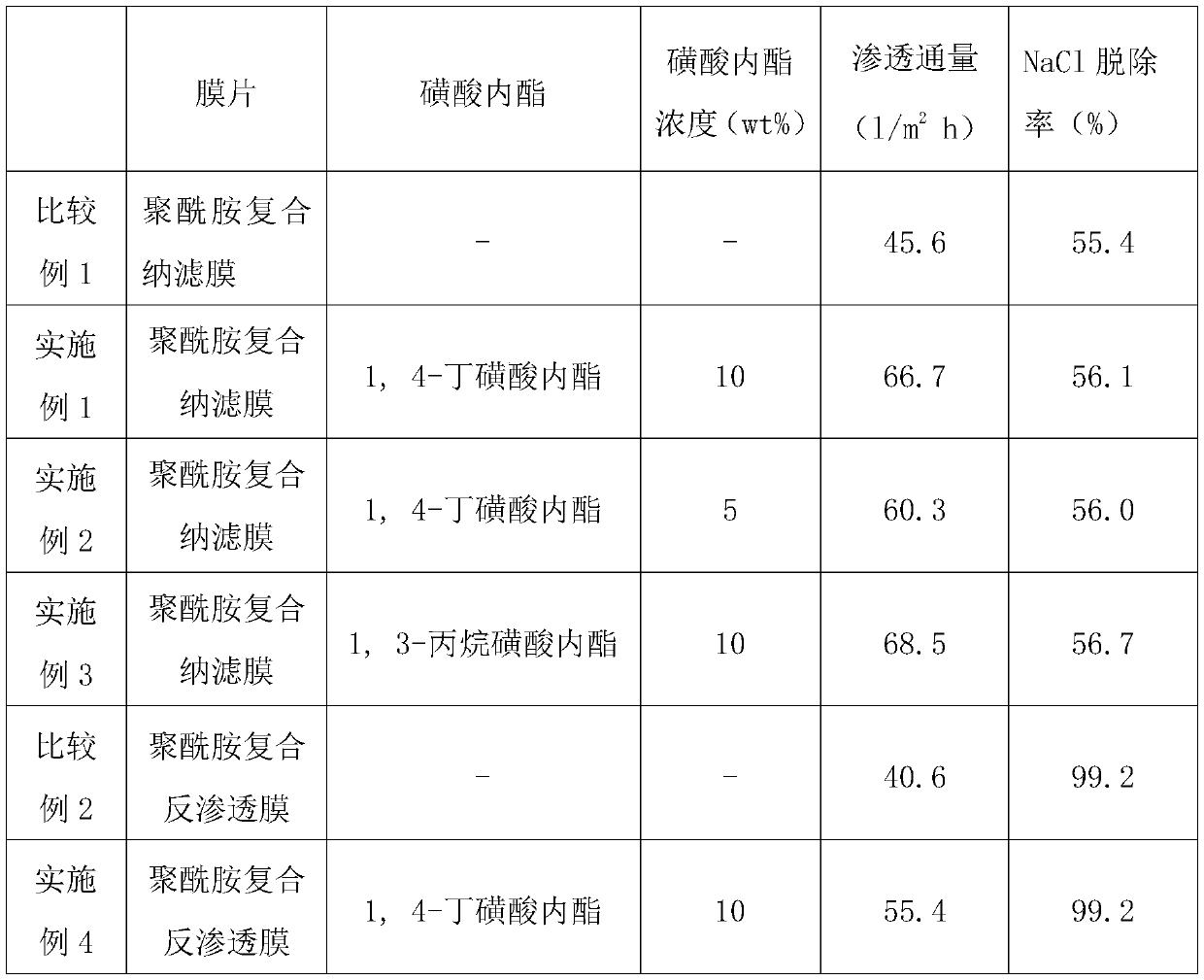

[0020] The commercialized polyamide composite nanofiltration membrane is washed with pure water, and the aqueous solution (pH=4.0 ) for 4 hours, take it out and wash it with pure water; then soak it in an ethanol / water (mass ratio 1:1) solution with a mass concentration of 1,4-butane sultone of 10%, after 15 hours Take it out and wash it with pure water, set aside.

[0021] The salt rejection rate and water flux of the nanofiltration membrane were tested under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0-8.0. The results are shown in Table 1.

Embodiment 2

[0023] The commercialized polyamide composite nanofiltration membrane is washed with pure water, and the aqueous solution (pH=4.0 ) for 4 hours, take it out and wash it with pure water; then soak it in 1,3-propane sultone mass concentration of 10% ethanol / water (mass ratio 1:1) solution, after 15 hours Take it out and wash it with pure water, set aside.

[0024] The salt rejection rate and water flux of the nanofiltration membrane were tested under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0-8.0. The results are shown in Table 1.

Embodiment 3

[0026] The commercialized polyamide composite nanofiltration membrane is washed with pure water, and the aqueous solution (pH=4.0 ) for 4 hours, take it out and wash it with pure water; then soak it in an ethanol / water (mass ratio 1:1) solution with a mass concentration of 1,3-propane sultone of 5%, after 15 hours Take it out and wash it with pure water, set aside.

[0027] The salt rejection rate and water flux of the nanofiltration membrane were tested under the conditions of NaCl concentration of 500mg / l, pressure of 0.5MPa, temperature of 25°C, and pH value of 7.0-8.0. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com