Fully-integrated electric vehicle flasher driving chip

A technology for integrating electric vehicles and driver chips, applied in the direction of electrical components, etc., can solve the problems of inconspicuous flickering of turn signals, non-existence, and low reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

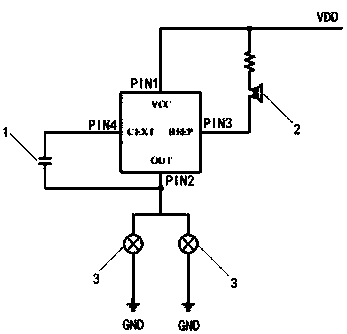

[0066] see figure 2 As shown, a fully integrated electric vehicle flasher drive chip, the external package of the drive chip has four pins, respectively VCC pin PIN1, OUT pin PIN2, BEEP pin PIN3 and CEXT pin PIN4, the The peripheral circuit structure of the drive chip is that the VCC pin PIN1 is connected to the battery power supply terminal VDD, a CEXT capacitor 1 is connected between the CEXT pin PIN4 and the OUT pin PIN2, and the BEEP pin PIN3 is connected to the OUT pin PIN2. A passive buzzer 2 is connected between the battery power supply terminal VDD, and a light bulb 3 is connected between the OUT pin PIN2 and the ground terminal GND;

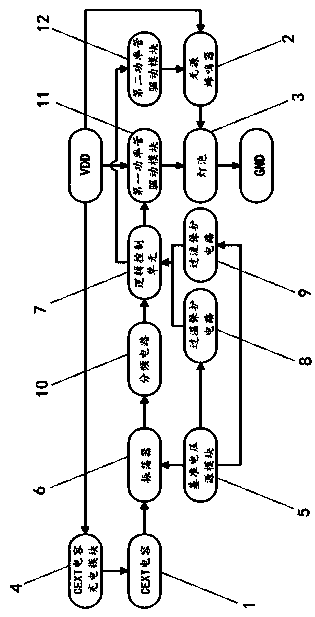

[0067] see figure 1 As shown, the internal integration of the driver chip includes a CEXT capacitor charging module 4, a reference voltage source module 5, an oscillator 6, a logic control uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com