Chemical fiber cotton fiber filling material and manufacturing method thereof

A filling material and chemical fiber technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of high cost, reduced warmth retention, insufficient bulkiness, etc., to increase practicability and service life, and improve the ability of washing resistance , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

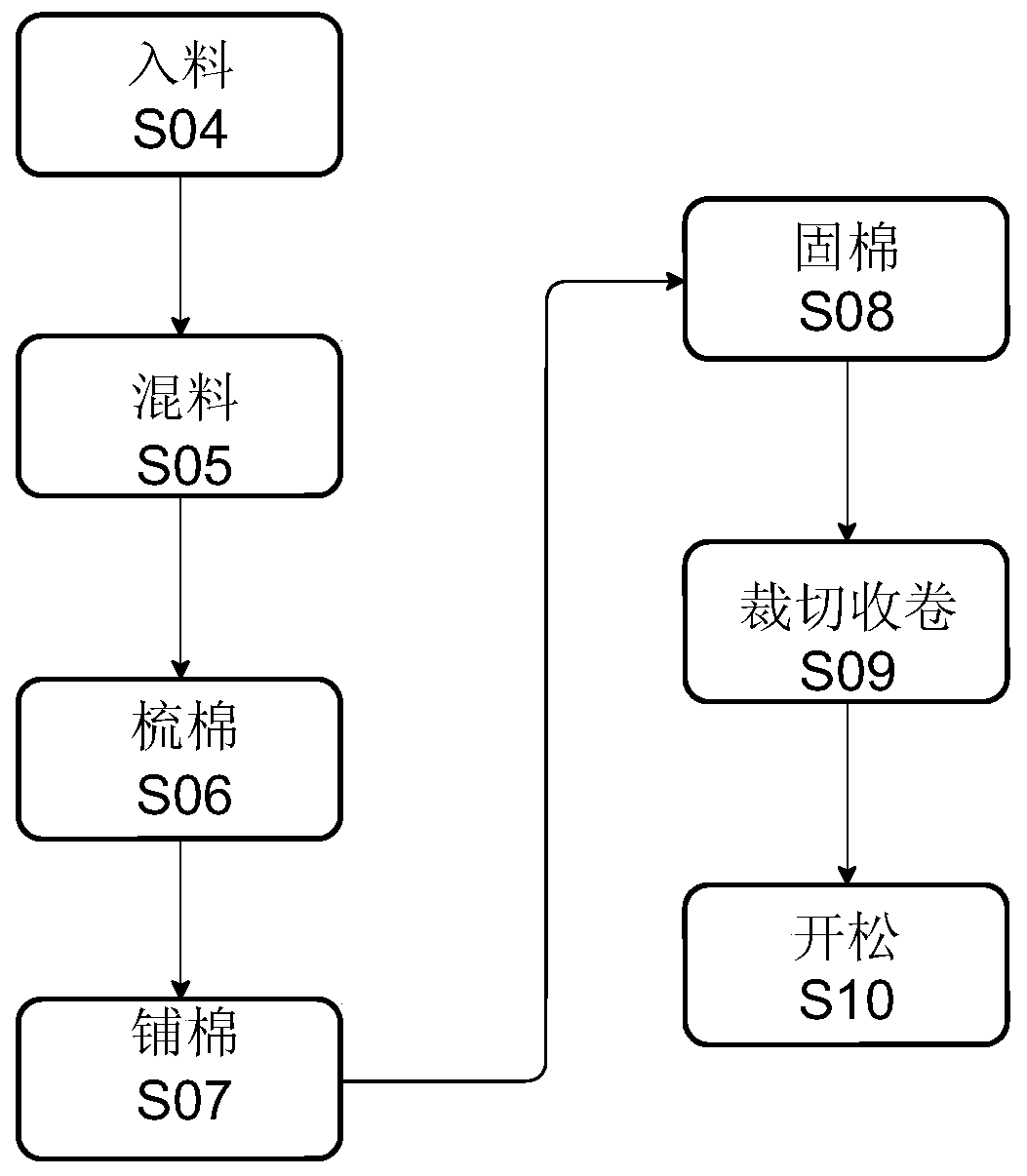

[0024] The present invention provides a manufacturing process of chemical fiber batting filling materials, which may comprise more than two types of fiber materials. In this embodiment, two types of fiber materials are used, one of which is chemical fiber material and the other is natural fiber material.

[0025] see figure 1 , the natural fiber material is mainly made of feathers of poultry animals (such as ducks, geese or water islands, etc.).

[0026] The step S01 of obtaining materials is to firstly select appropriate down and down materials. The feathers of poultry animals are of different lengths, ranging from 1cm to 15cm in length. Feathers with high down content and good warmth retention are of considerable value and are suitable as natural down, while feathers with low down content and poor warmth retention, such as Longer feathers such as big flight feathers (thick wings), big wings, and two wings are leftovers with low market value and are not suitable as natural d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com