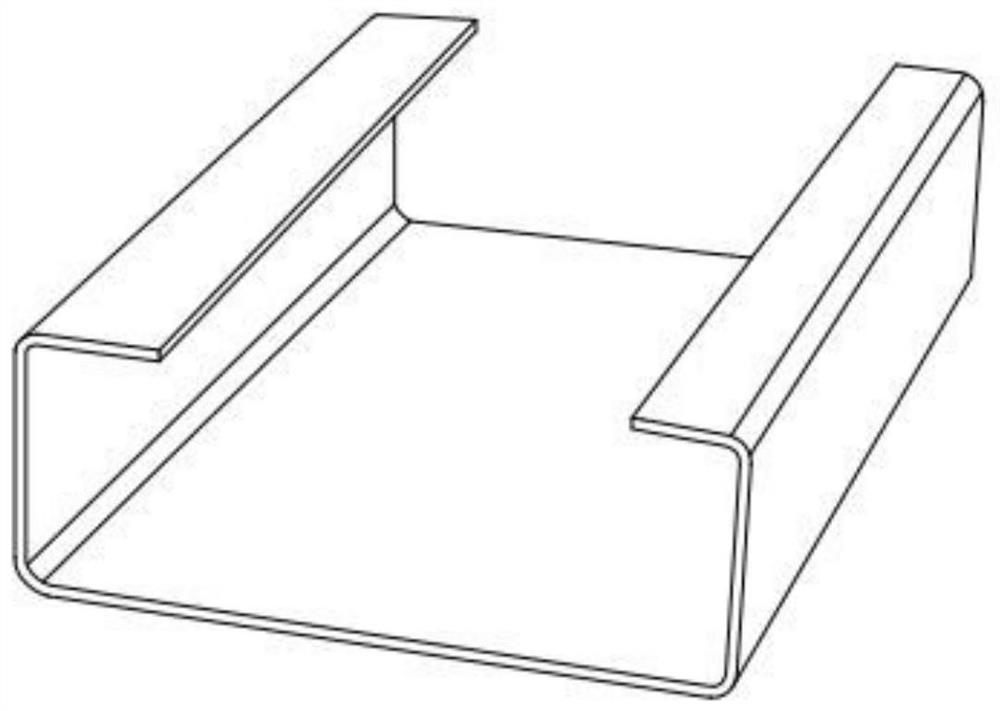

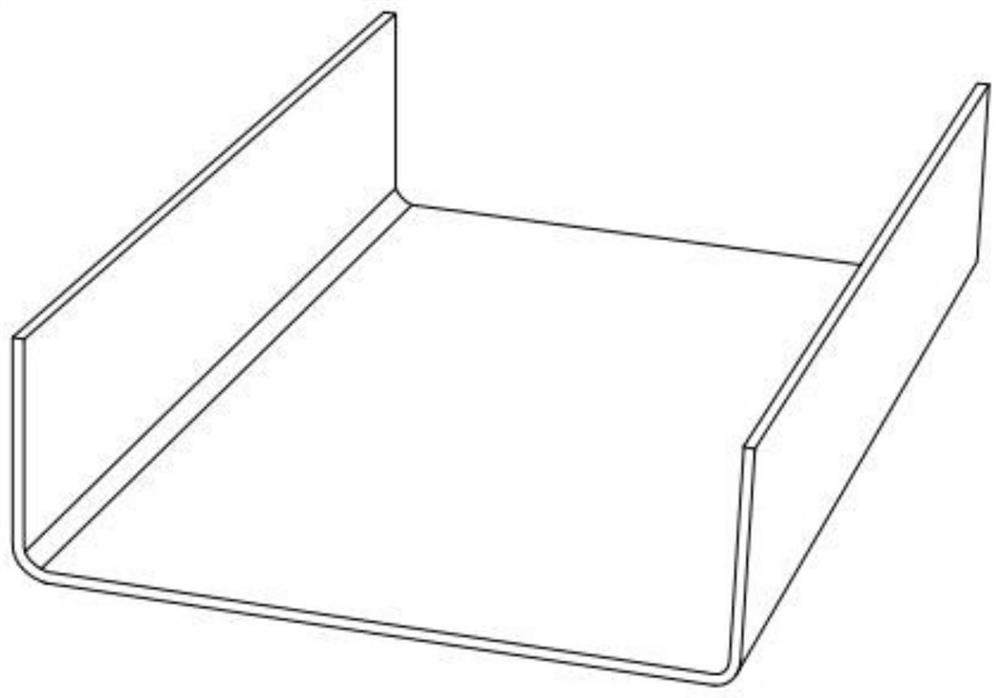

C-shaped steel stacking device

A technology of C-section steel and section steel, applied in the stacking, transportation and packaging of objects, conveyor objects, etc., can solve the problems of low degree of automation, low efficiency, waste of manpower, etc., and achieve the effect of reducing the amount of manual labor and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

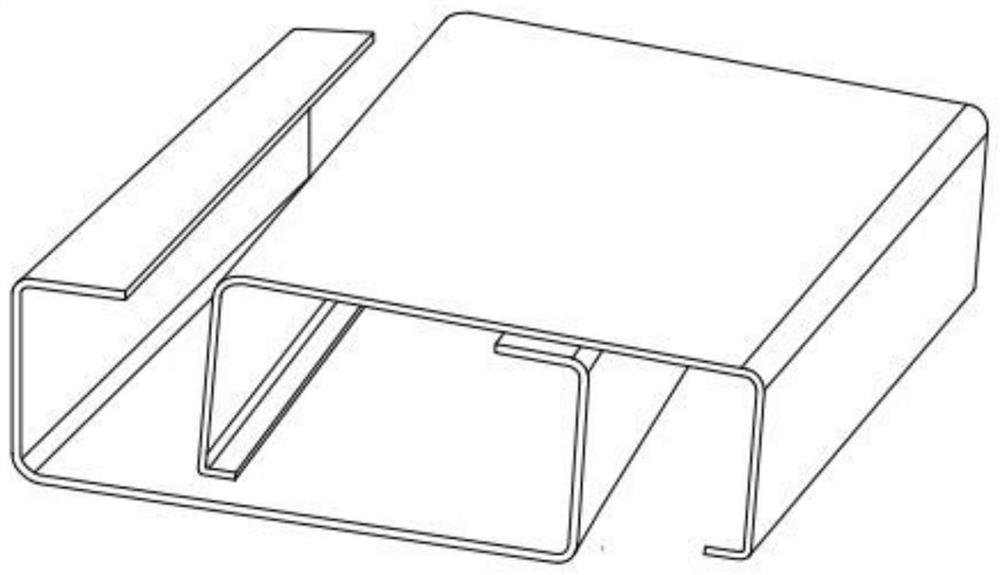

[0047] see Figure 5-14 As shown, the C-shaped steel stacking device includes:

[0048] The material receiving table 30 is arranged on one side of the shaped steel discharge port 100. The material receiving table 30 is provided with a first limit plate 31 for aligning the rectangular direction of the shaped steel. A moving assembly of a limiting plate 31,

[0049] The transfer assembly 50 is located on the corresponding side of the push assembly of the material receiving platform 30, and the transfer assembly 50 is used for section steel transfer,

[0050] The material receiving mechanism 60 is located in the discharge direction of the transmission assembly 50. The material receiving mechanism 60 includes a vertically arranged second frame body 62, and a hydraulic cylinder 65 for lifting the second frame body 62 is installed at the bottom of the second frame body 62. The sides corresponding to the two frames 62 and the conveying assembly 50 are respectively provided with a f...

Embodiment 2

[0073] When the C-shaped steel stacking device of the present invention is actually used:

[0074] Realize setting the device in the discharge direction of the C-shaped steel cutting discharge port 100 or the discharge direction of the discharge port 100 at the cold pressing device;

[0075] After the shaped steel is discharged from the discharge port, the discharged shaped steel is firstly received by the provided receiving table 30, and the first limiting plate 31 is used to limit the sliding distance of the discharged shaped steel, that is Alignment operation on section steel;

[0076] After finishing the profile alignment operation, the aligned profile steel is pushed towards the conveying assembly 50 using the pushing assembly arranged on one side of the material receiving table 30, and the process of conveying the profile steel on the conveying assembly 50 can effectively find defective profile steel and reject waste products, thereby Improve the stacking quality of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com