Compensation valve applied to hydrostatic braking system and hydrostatic braking system

A braking system and compensating valve technology, applied in the direction of hydraulic brake transmission, brake transmission, brakes, etc., can solve the problems of incomplete release of brake, inability to release, brake hysteresis, etc., and achieve rapid and thorough brake release , The effect of sensitive braking response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

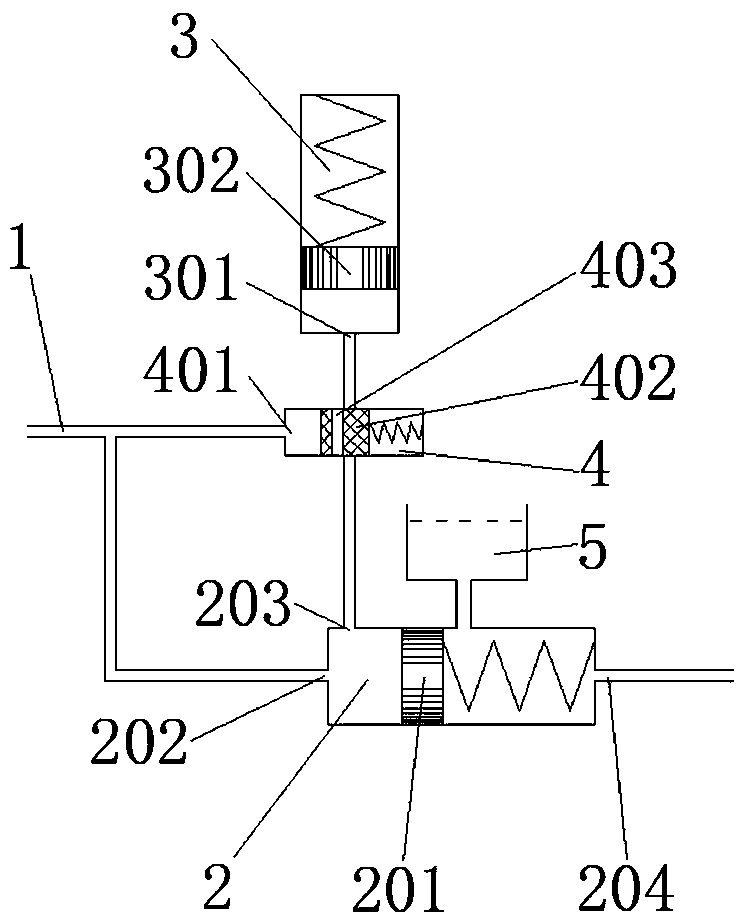

[0026] like figure 1 As shown, the purpose of the present invention is to propose a compensation valve, including: an input pipeline 1 for inputting liquid medium; an isolation chamber 2, in which an isolation piston 201 is provided, and the isolation piston 201 divides the cavity into left and right cavity and a right cavity, the left cavity is provided with a first liquid inlet 202 and a liquid replenishment port 203, and the first liquid inlet 202 is connected to the input pipeline 1; the right cavity is provided with a liquid outlet 204 for Output liquid medium, the isolation piston 201 is connected to the cavity near the liquid outlet 204 through a spring; the energy storage chamber 3 is used to store high-pressure liquid medium, and is provided with a pressure relief port 301, and the pressure relief port 301 is connected to the liquid replenishment port 203 is connected to form a compensation pipeline; the normally closed valve 4 is set on the compensation pipeline and ...

Embodiment 2

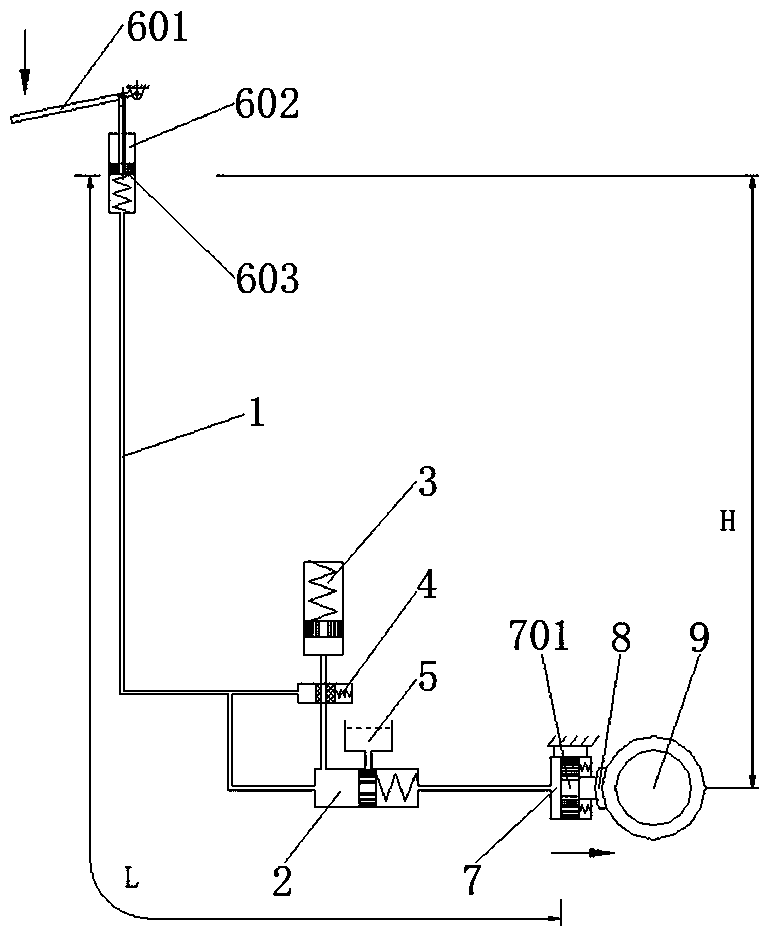

[0031] The present invention also proposes a static pressure braking system, which includes the above-mentioned compensating valve, the control end, and the brake chamber 7, the control end is connected with the input pipeline 1, and is used to push the liquid medium in the pipeline; the system The moving chamber 7 is connected to the liquid outlet 204, and a brake piston 701 is arranged inside through a spring, and the liquid medium enters the brake chamber 7 to push the brake piston 701 for braking.

[0032] In this embodiment, the operating end includes an operating rod 601 and an operating chamber 602, the operating rod 601 is connected to an operating piston 603 in the operating chamber 602, and the operating piston 603 is connected to the operating chamber 602 through a spring. The brake piston 701 is connected with a brake pad 8, and the brake pad 8 cooperates with a brake hub 9. When the brake piston 701 brakes, the brake pad 8 is driven to press the brake hub 9 to comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com