Electric mainshaft bearing pre-tightening device, electric mainshaft and machine tool

An electric spindle and bearing technology, which is used in metal processing machinery parts, large fixed members, metal processing and other directions, can solve the problems of unstable change of spring force, poor control accuracy of preloading force, and poor protection effect of electric spindle. To achieve the effect of high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

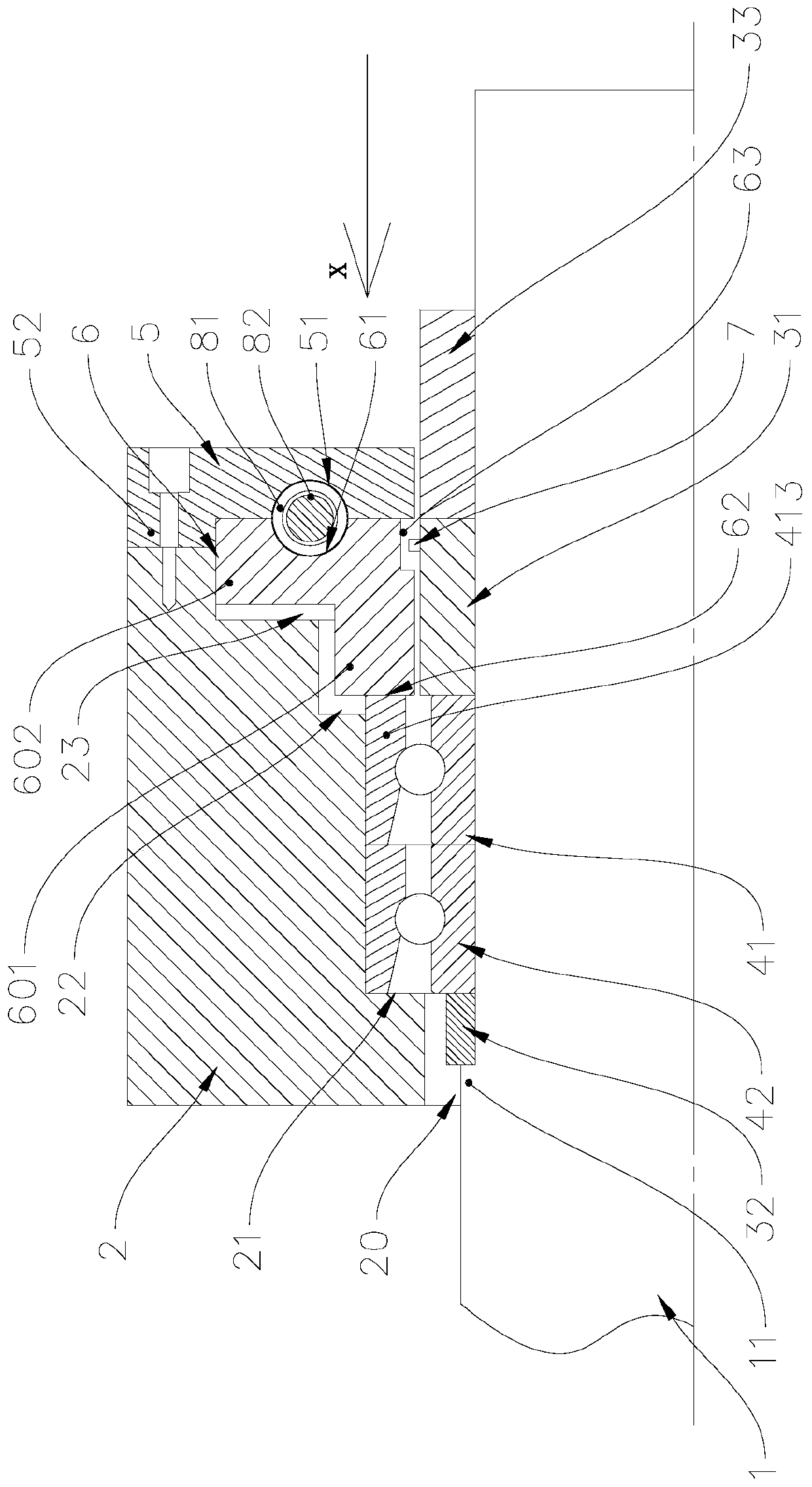

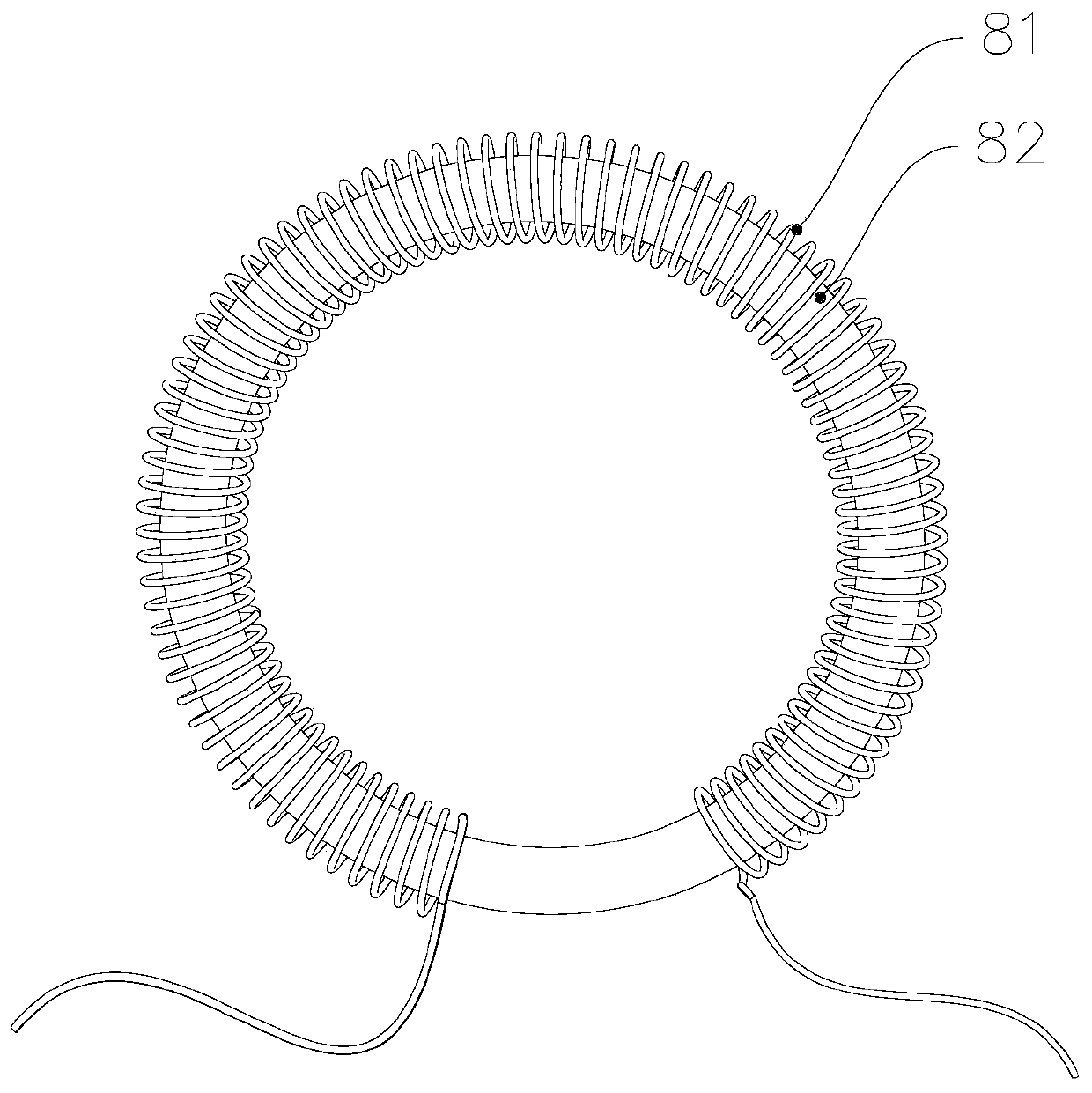

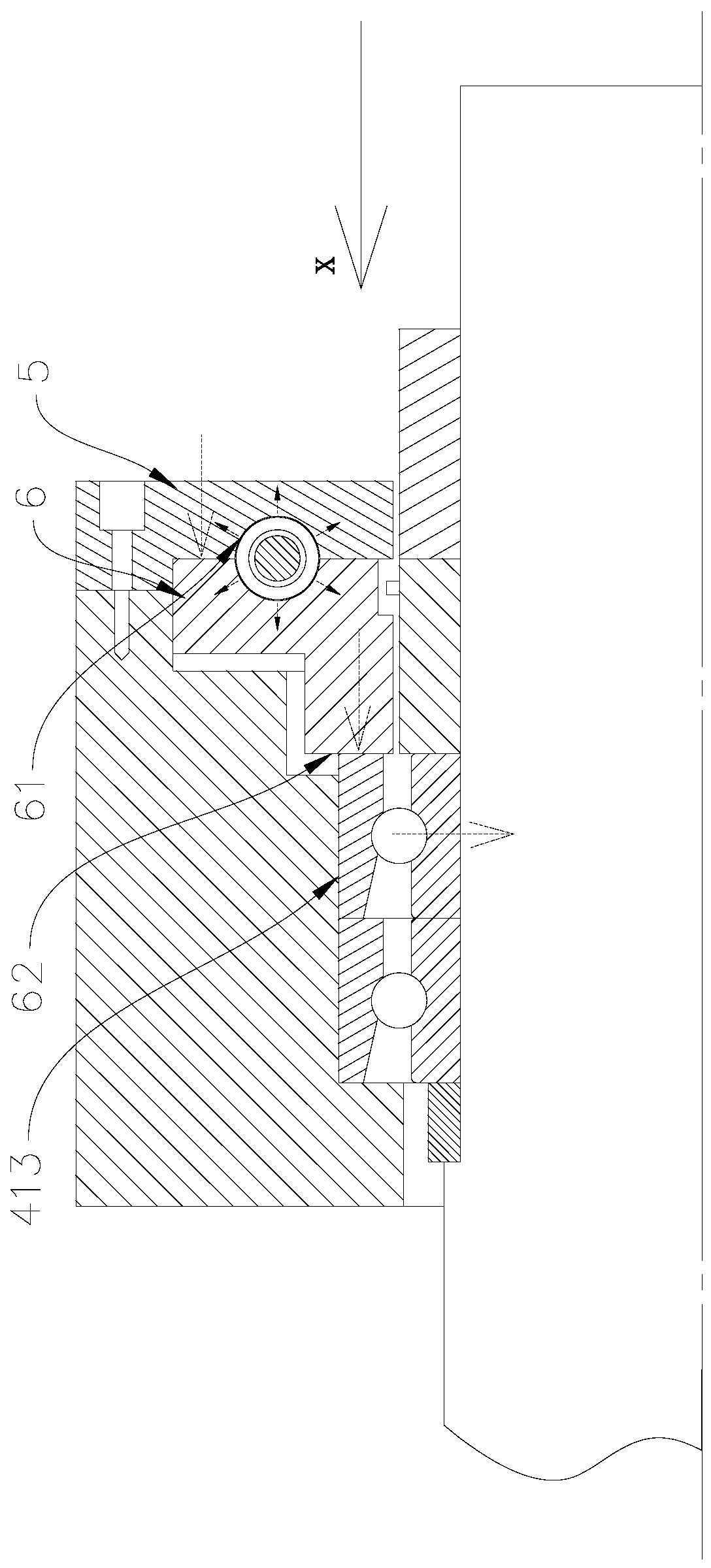

[0038] see figure 1 , figure 1 It is a cross-sectional view of some components of the first embodiment of the electric spindle of the present invention. The machine tool provided by the present invention is a CNC machine tool or a non-NC machine tool. The machine tool has an electric spindle. Bearing 41, second angular contact bearing 42, end ring 5, compression sleeve 6, spiral coil 81, iron core 82 and coil controller (not shown in the figure). The end ring 5, the compression sleeve 6, the helical coil 81, the iron core 82 and the coil controller constitute the electric spindle bearing pretensioning device of the present invention.

[0039] There is a shaft shoulder 11 on the main shaft body 1, the second spacer ring 32, the second angular contact bearing 42, the first angular contact bearing 41, and the first spacer ring 31 are sequentially fitted outside the main shaft body 1 along the positive direction of the x-axis. The ring 32 is a small spacer ring, the second spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com