Aggregate screening, washing and baking integration machine

A screening and integrated technology, applied in the direction of dryer, drying, drying gas arrangement, etc., can solve problems such as difficulty in finding a drying environment, cumbersome manual operation steps, time-consuming and laborious, and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

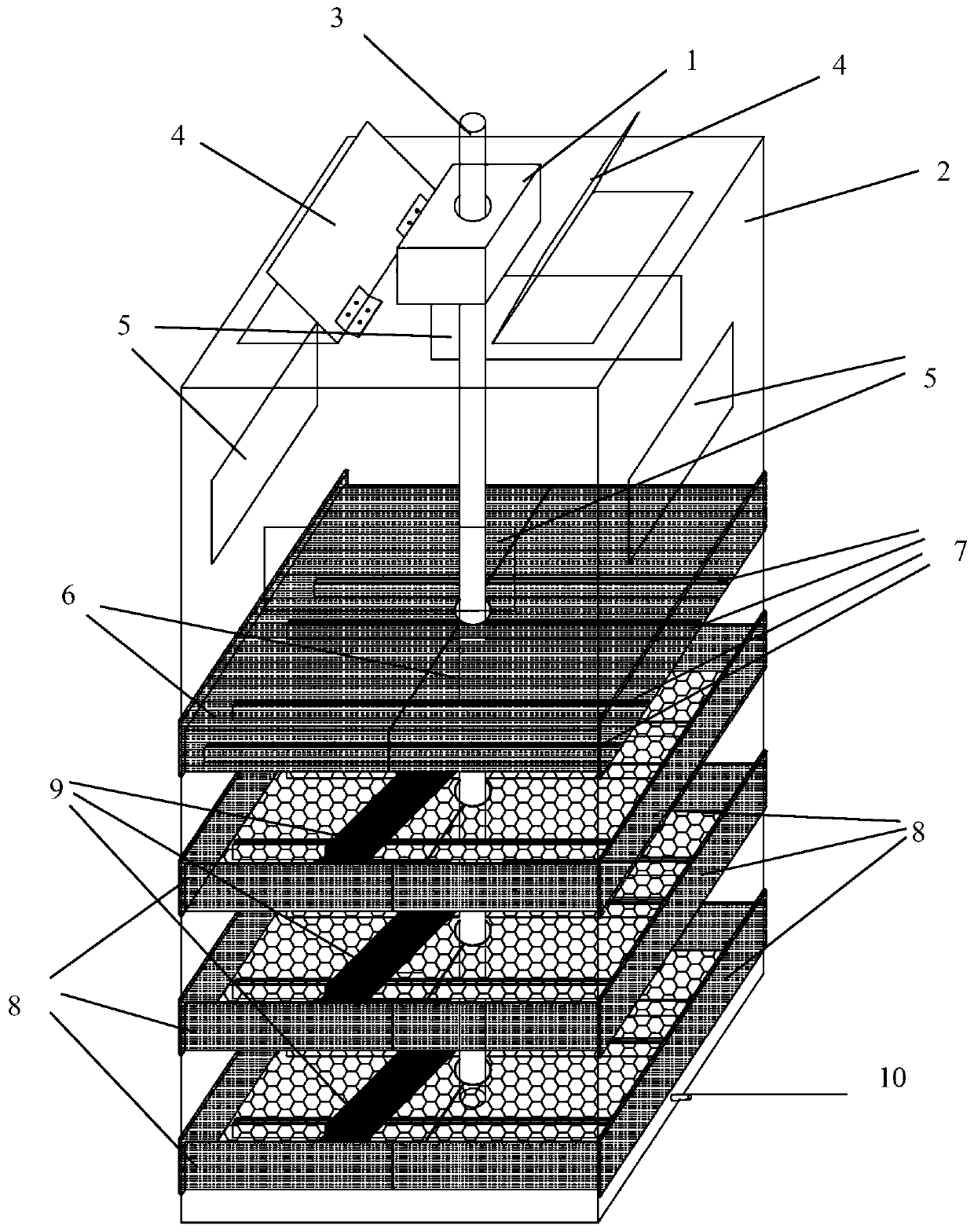

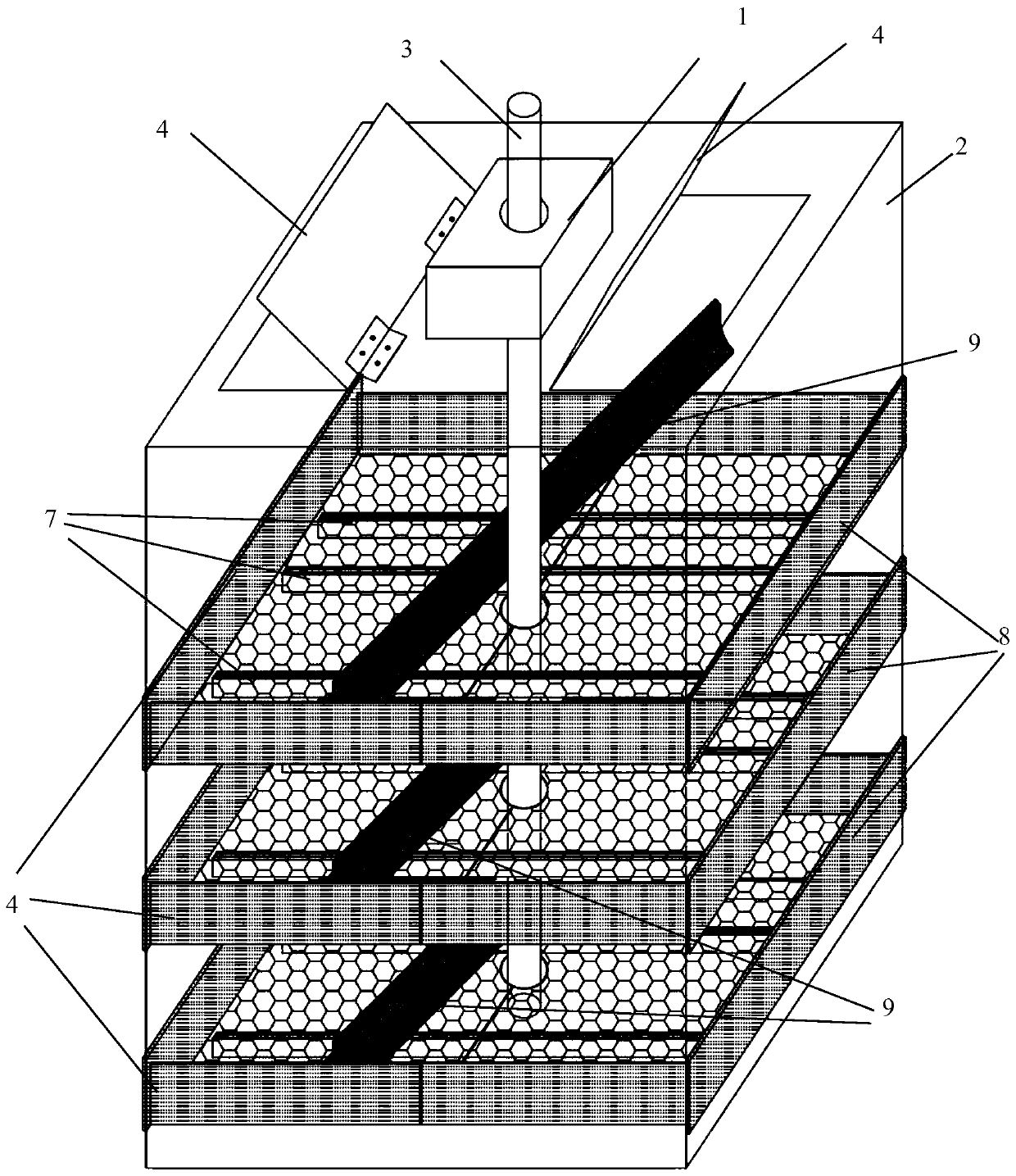

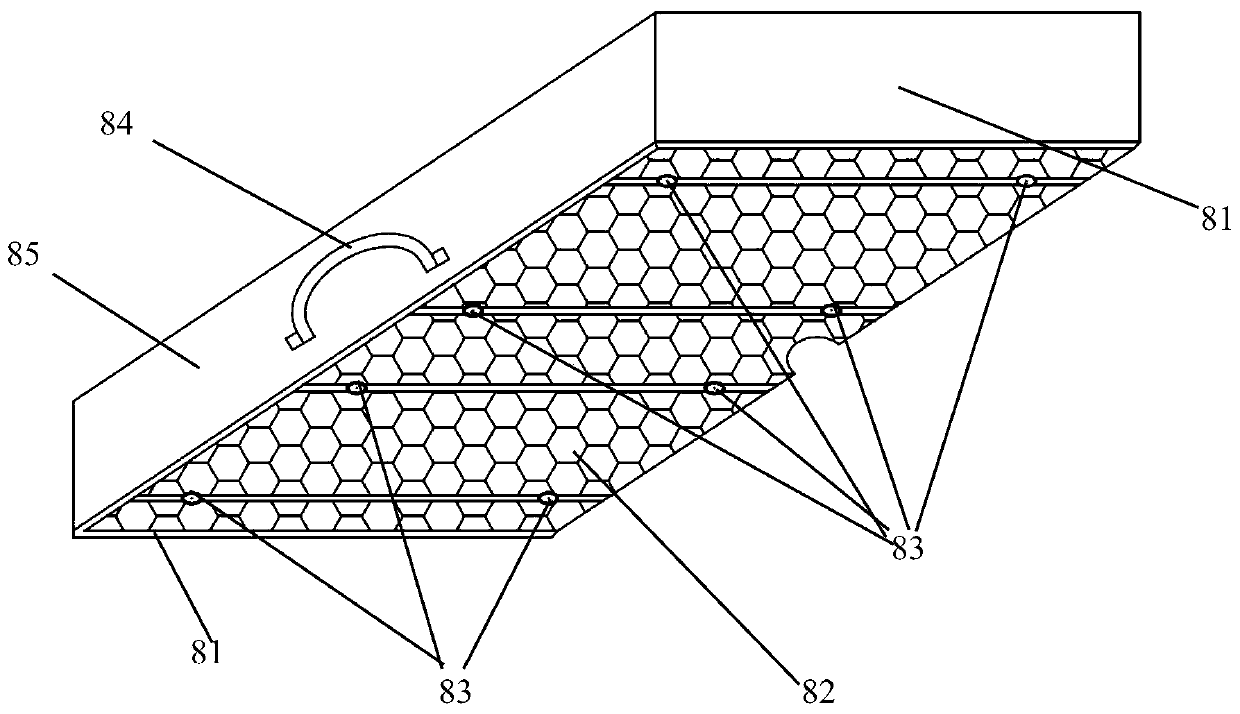

[0018] As shown in the figure, an aggregate screening, washing and drying machine includes a motor 1, a box body 2, a sieve drawer 8, a shower 6, a track 7, a bearing 3 and a stirring tooth 9. The box body has four drawer openings on the left and right sides, four rails 7 are installed below each layer of openings, and the four walls above the box body 2 are provided with four hot air outlets 5 . The motor 1 is arranged on the casing 2 , and the bearing 3 passes through the motor 1 and the casing 2 . The motor 1 is installed in the center of the upper surface of the box body 2 to drive the bearing 3 to rotate. The stirring teeth 9 are mounted on the bearing 3 in groups of two, and the installation position is 20 mm above the track (except for the uppermost layer). Described sieve drawer 8 is made up of two drawer sidewalls 81, a drawer face 85, eight wheels 82, a drawer handle 84 and screen cloth 82, reserves a semicircle gap in the middle position of screen cloth 82 edges. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com