A food processor with good cleaning effect

A food processing machine and machine body technology, which is applied to utensils, kitchen utensils, household utensils, etc. with integral electric heating devices, and can solve the problems of poor sealing effect, sealing problems, etc. problems, to achieve the effect of convenient installation, improving sealing reliability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

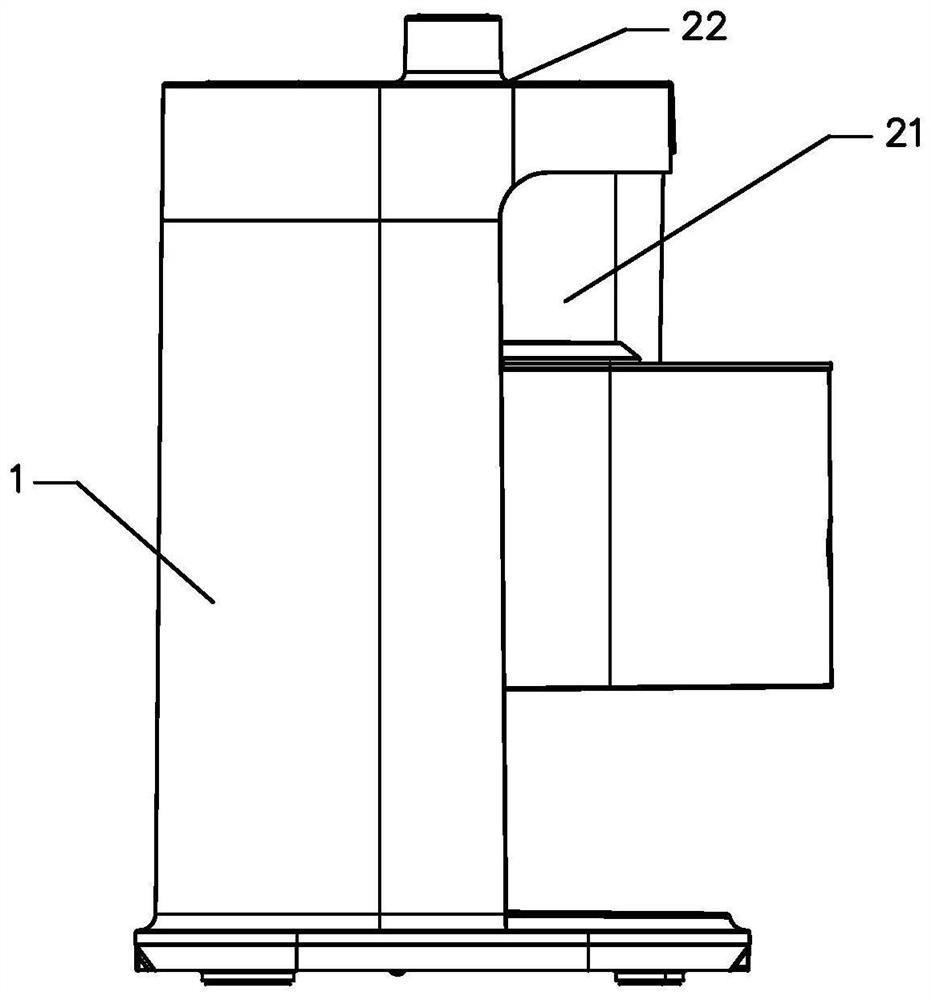

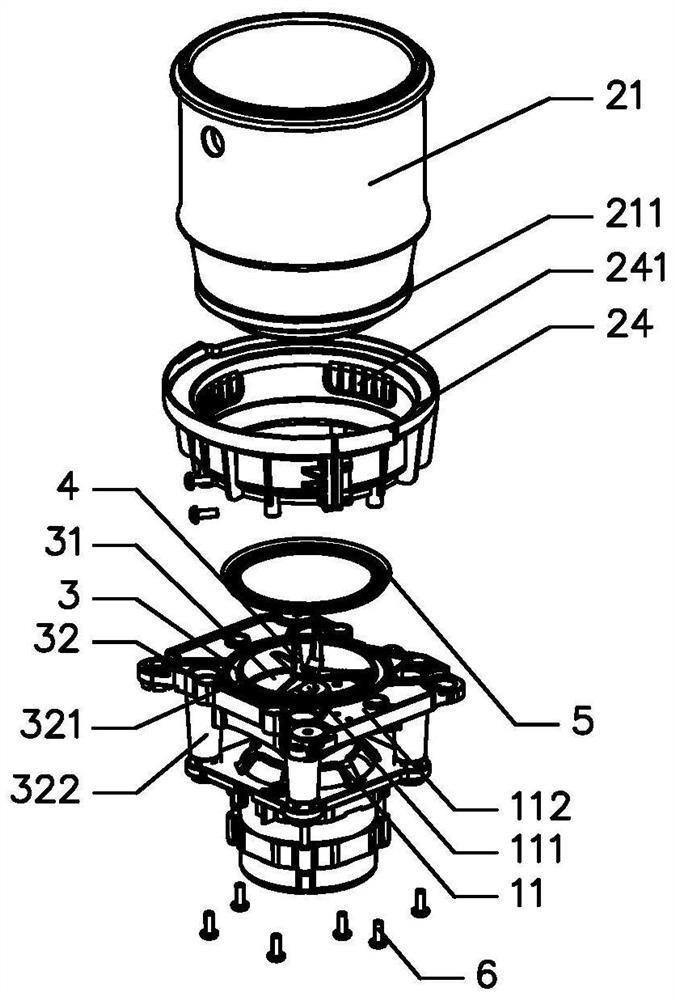

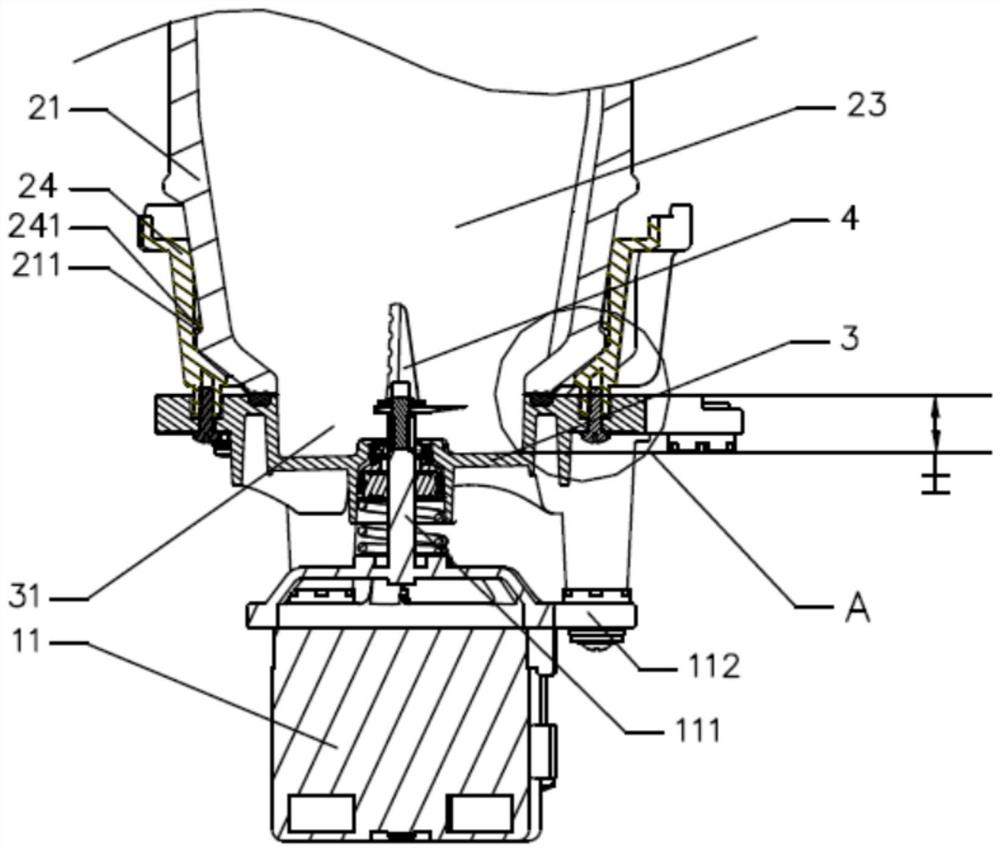

[0043] like Figure 1 to Figure 4 As shown, the present invention provides a food processor with reliable sealing, including a machine body 1, a motor 11, a crushing cup body and a crushing cup cover 22, the crushing cup body is fixedly connected to the body 1, and the crushing cup body includes an upper and lower The glass cup body 21, the metal plate 3 and the cup body bracket 24 with openings, the metal plate 3 is sealed and installed on the lower opening of the glass cup body 21, and the crushing cup cover 22 is closed on the upper opening of the glass cup body 21, and the crushing cup The cover 22, the glass body 21 and the metal plate 3 form a pulping chamber 23 surrounded by a pulverizing device 4, which is specifically a pulverizing knife, and the pulverizing knife is connected to the motor 11 through transmission.

[0044] In this embodiment, the crushing cup body includes a glass body 21. The surface of the glass body 21 is smooth and easy to clean, and the glass bod...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the upper outer ring of the sealing ring is provided with an inward flanging, and at the joint between the glass body 21 and the metal plate 3, the inner side wall of the metal plate 3 is opposite to the glass body 21 The inner wall of the cup protrudes toward the center of the crushing cup body 2 .

[0061] In this example, if Figure 5 and Image 6 As shown, at the junction of the glass body 21 and the metal disc 3, the inner side wall of the metal disc 3 protrudes toward the center of the crushing cup body 2 relative to the inner side wall of the glass body 21, so that the metal disc 3 and the glass A relatively small step is formed between the body 21. When the material and water in the metal plate 3 are driven by the pulverizer 4 and move, the material and the pulverizer 4 are continuously collided and crushed to form, while the mixture of slurry and material Driven by the crushing knife 4, it rotate...

Embodiment 3

[0071] The difference between this embodiment and the second embodiment is that the upper end of the sealing ring is also provided with an outer flange.

[0072] In this example, if Figure 7 As shown, the sealing ring 5 is also provided with an outer flange 52 extending out of the glass body 21 surrounding the annular mounting portion 53. The outer flange 52 is arranged on the upper end of the annular mounting portion 53 and is inclined upward. Set to cover the outer side of the bottom end surface of the glass cup body 21, so that through the joint action of the inner and outer flanges, the bottom end surface of the glass cup body and the metal plate can better realize complete soft contact. It can better guarantee the durability and service life of the glass body.

[0073] The optimal range of the height h of the inner wall of the metal disc 3 protruding toward the center of the crushing cup relative to the inner wall of the glass body 21 is 0.2 to 1mm. Within this range, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com