Tobacco cutter and control method thereof

A control method and cutting machine technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of equipment use troubles, inconvenience, and a lot of time and manpower, so as to reduce the time and frequency of blade replacement , space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

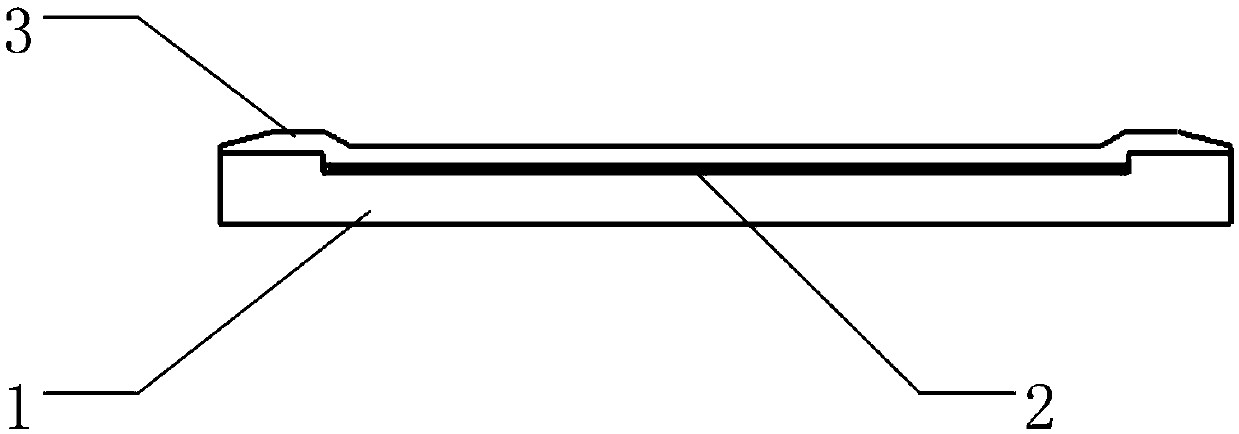

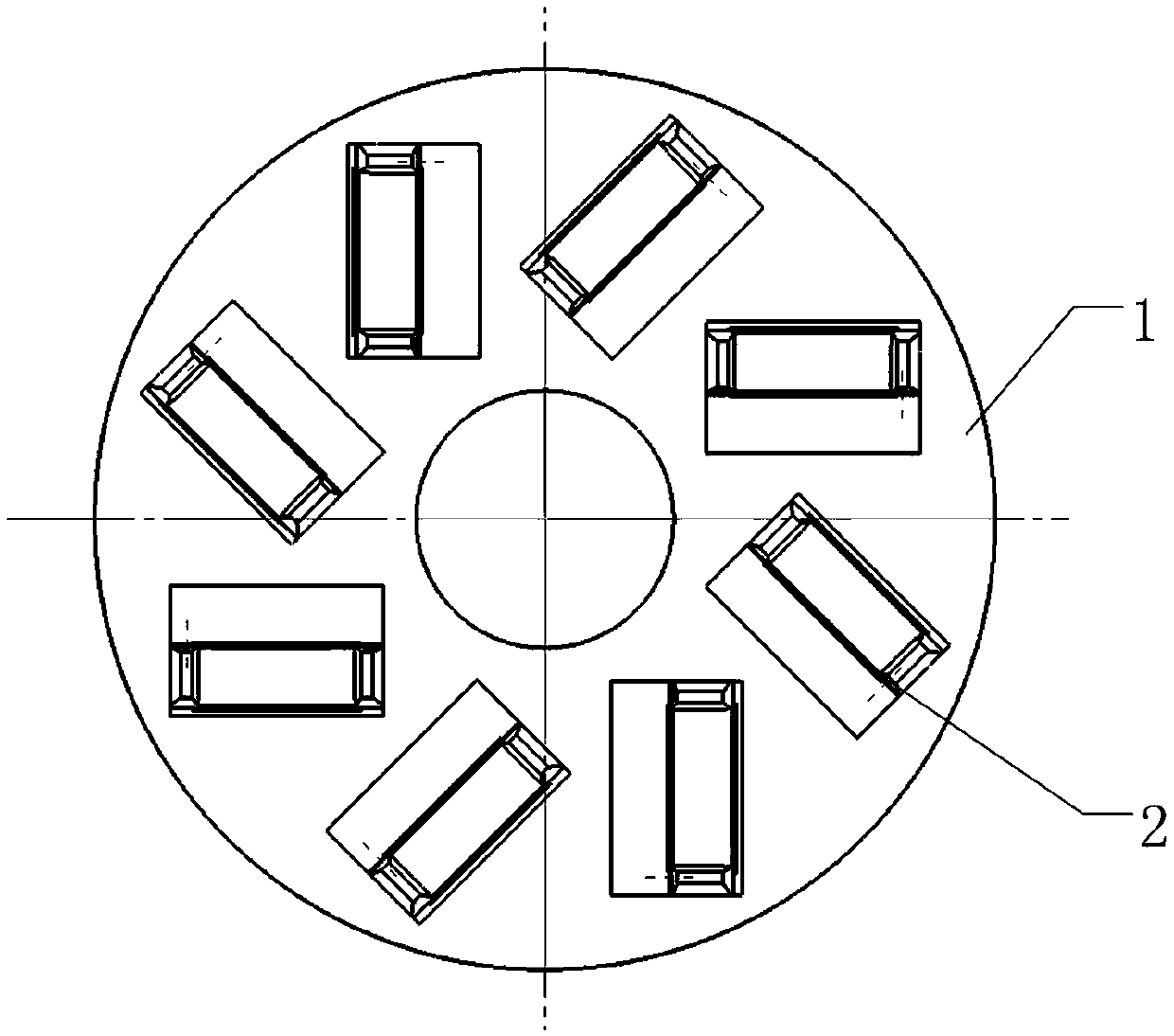

[0054] The transmission part in this embodiment is a gear, and the limiting slot of the blade is a rack structure matched with the gear.

[0055] There are two symmetrically arranged gears on the feeding side of the blade 2, and the gears can be connected to the motor through other transmission parts, so that the motor drives the gear in contact with the blade to rotate.

[0056] The feeding side of the blade 2 is provided with a rack structure, and can engage with the gear. When the motor drives the gear to rotate, the rack structure at one end of the blade 2 is engaged with the gear earlier, and the direction of rotation of the gear is to be able to The direction in which the blade 2 moves to the feed direction, generally the gear on the right side of the blade 2 rotates clockwise, and the gear on the left side of the blade 2 rotates counterclockwise. The two gears have the same structure and speed, and can drive the blade 2 to move forward. .

[0057] With the rotation of ...

Embodiment 2

[0060] This example figure 2 As shown, the transmission part of the feeding device is a screw 11 , and the blade 2 is provided with a thread surface matching the thread of the screw 11 .

[0061] The blade has a certain thickness, so that the threaded surface can be formed on the side. The screw 11 is connected to the motor or connected to the drive through a transmission part. Helical movement, the blade 2 is provided with a thread surface matching the thread of the screw rod 11 on the feed side, when the screw rod 11 rotates, the raised thread can snap into the thread surface of the blade 2 feed side, and It can drive the blade 2 to move in the feeding direction.

[0062] The inclination direction of the thread is consistent with the inclination direction of the groove on the thread tooth surface to ensure that the screw 11 can drive the blade 2 to move. The specific parameters are set according to the design manual or actual needs. Those skilled in the art can achieve the...

Embodiment 3

[0065] The transmission components in this embodiment are lead screws and lead screw nuts, and protrusions are arranged on the blade 2 .

[0066] The screw and the screw nut can convert the rotational motion of the screw to the linear motion of the screw and nut along the screw through structures such as balls in the middle.

[0067] The lead screw nut is sleeved on the lead screw, and the linear motion is realized by the movement of the thread and the ball. The lead screw nut is provided with a nut protrusion, and the direction of the nut protrusion is the direction of the blade 2, and is aligned with the blade 2 for matching, the feeding side of the blade 2 is provided with a limit card slot matching with the nut protrusion, and a groove can be provided. When the screw rotates, it drives the screw nut to move back and forth. After the nut protrusion of the lead screw nut is snapped into the groove, the rotation of the screw rod drives the nut to move in the feeding direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com