C-shaped wire clamp mounting tool and using method thereof

An installation tool and wire clip technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inability to meet the installation specifications of distribution line wire clips, C-type wire clips cannot be installed vertically, etc., to achieve simple structure, labor-saving operation, and convenience. The effect of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

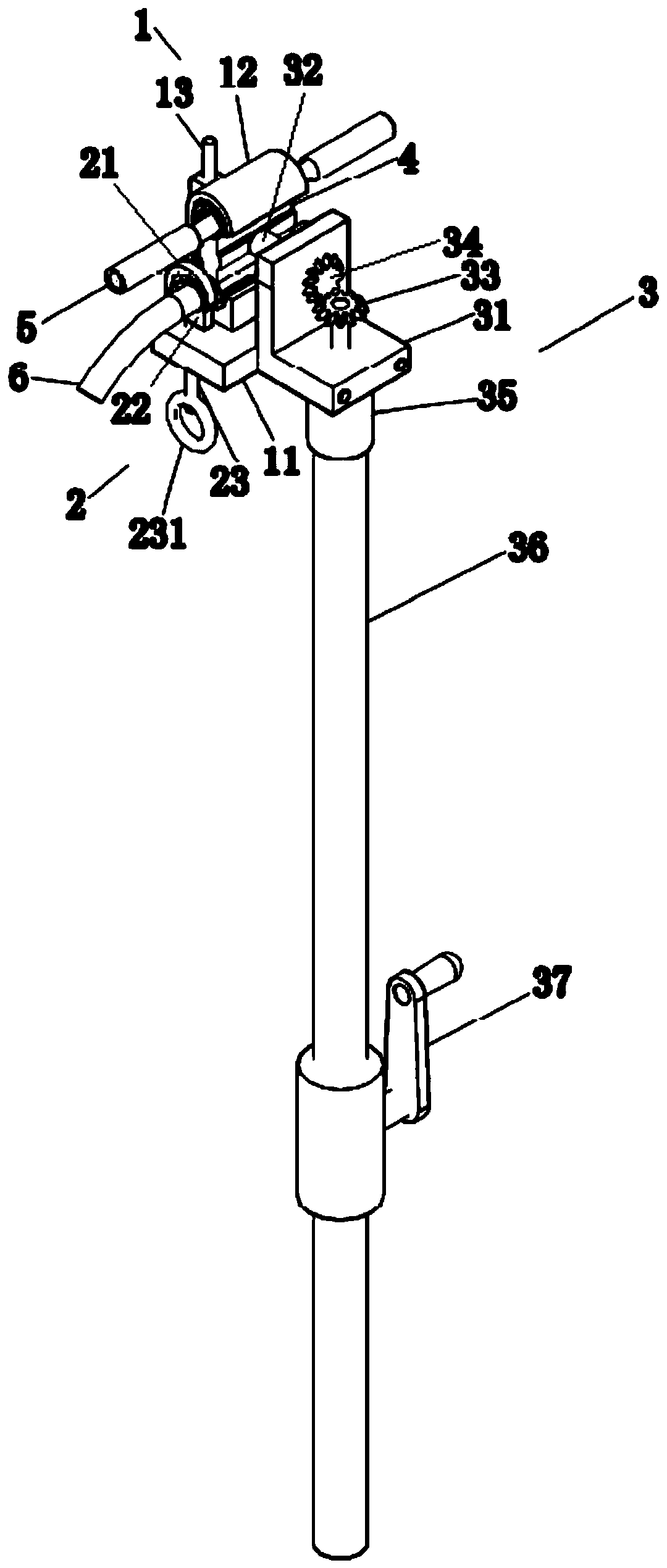

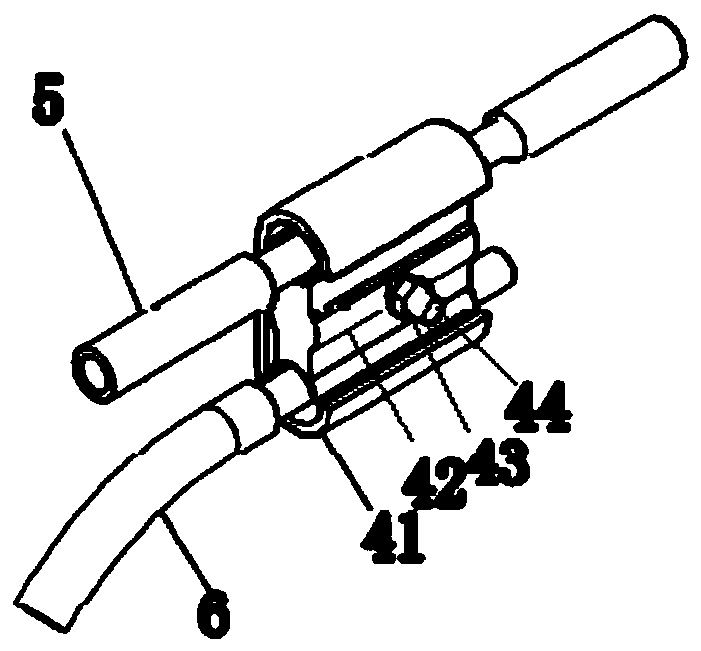

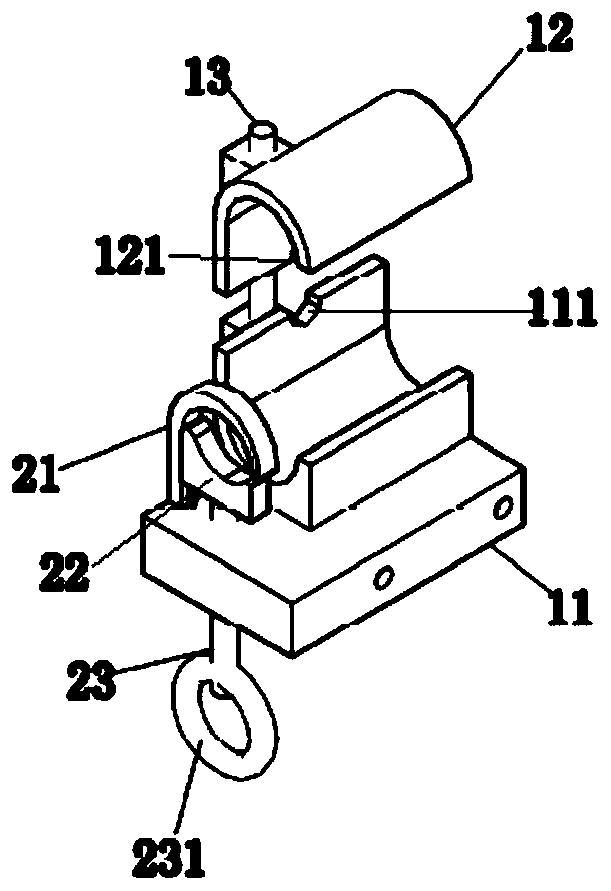

[0034] For examples, see Figure 1-5 As shown, a C-type wire clamp installation tool of the present invention includes a wire clamp clamping mechanism 1, a cable clamping mechanism 2, a wire clamp nut locking mechanism 3, and the wire clamp clamping mechanism 1 includes a fixed base 11, The movable base 12 and the first driving part, the movable base 12 is slidable relative to the fixed base 11, and is driven by the first driving part to open and close with the fixed base 11 to loosen or clamp the C-shaped wire clamp 4; The clamping mechanism 2 includes a fixed clamping member 21, a movable clamping member 22, and a second driving member. The fixed clamping member 21 is arranged on the fixed base 11, and the movable clamping member 22 is slidable relative to the fixed clamping member 21 and is driven by the second driving member. The drive and fixed clamp 21 are opened and closed to loosen or clamp the cable. Both the first driving part and the second driving part can be drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com