Ceramic Sanitary Ware Vertical Grouting Production Line

A production line and vertical technology, applied in the field of ceramic sanitary ware production equipment, can solve the problems affecting the yield and production efficiency, high labor intensity, large mold size, etc., to reduce the number of operators, reduce labor intensity, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

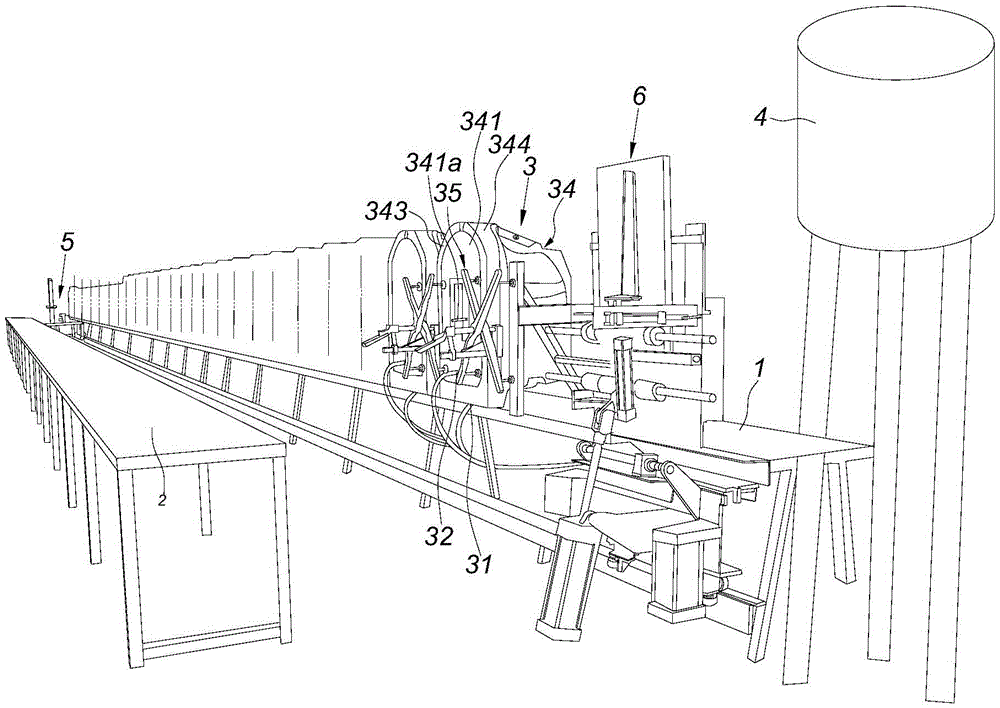

[0032] figure 1 A vertical grouting production line for ceramic sanitary ware according to an embodiment of the present invention is schematically shown.

[0033] Such as figure 1 As shown, the ceramic sanitary ware vertical grouting production line is used to produce split toilets, including a main workbench 1, an auxiliary workbench 2, a molding machine 3, a grouting device 4, a demoulding mechanism 5 and a blanking mechanism 6. The main workbench 1 and the auxiliary workbench 2 are arranged in parallel, the grouting device 4 and the stripping mechanism 6 are installed at the right end of the main workbench 1, the stripping mechanism 5 is installed at the left end of the main workbench 1, and multiple molding machines 3 are arranged side by side in sequence Placed on the main workbench 1, each molding machine 3 communicates with a grouting device 4.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com