Path generation and motion control method for shunt stacking machine

A technology of transition stacker and path generation, applied in the direction of digital control, program control, comprehensive factory control, etc., can solve problems such as inability to fundamentally detect and avoid task path conflicts, large communication volume between PLCs, and huge program volume. , to achieve the effect of efficient and reliable control, high execution efficiency, and small amount of communication data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention provides an electrical control method for track generation, path conflict detection, and linkage between stacker and turnout. The method includes the following four parts:

[0063] (1) Transition path generation method;

[0064] (2) Path conflict detection method;

[0065] (3) Transition command generation method;

[0066] ⑷ Turnout control and path state detection methods;

[0067] Method ⑴-⑶ is executed by stacker PLC, and method ⑷ is executed by conveying line PLC.

[0068] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

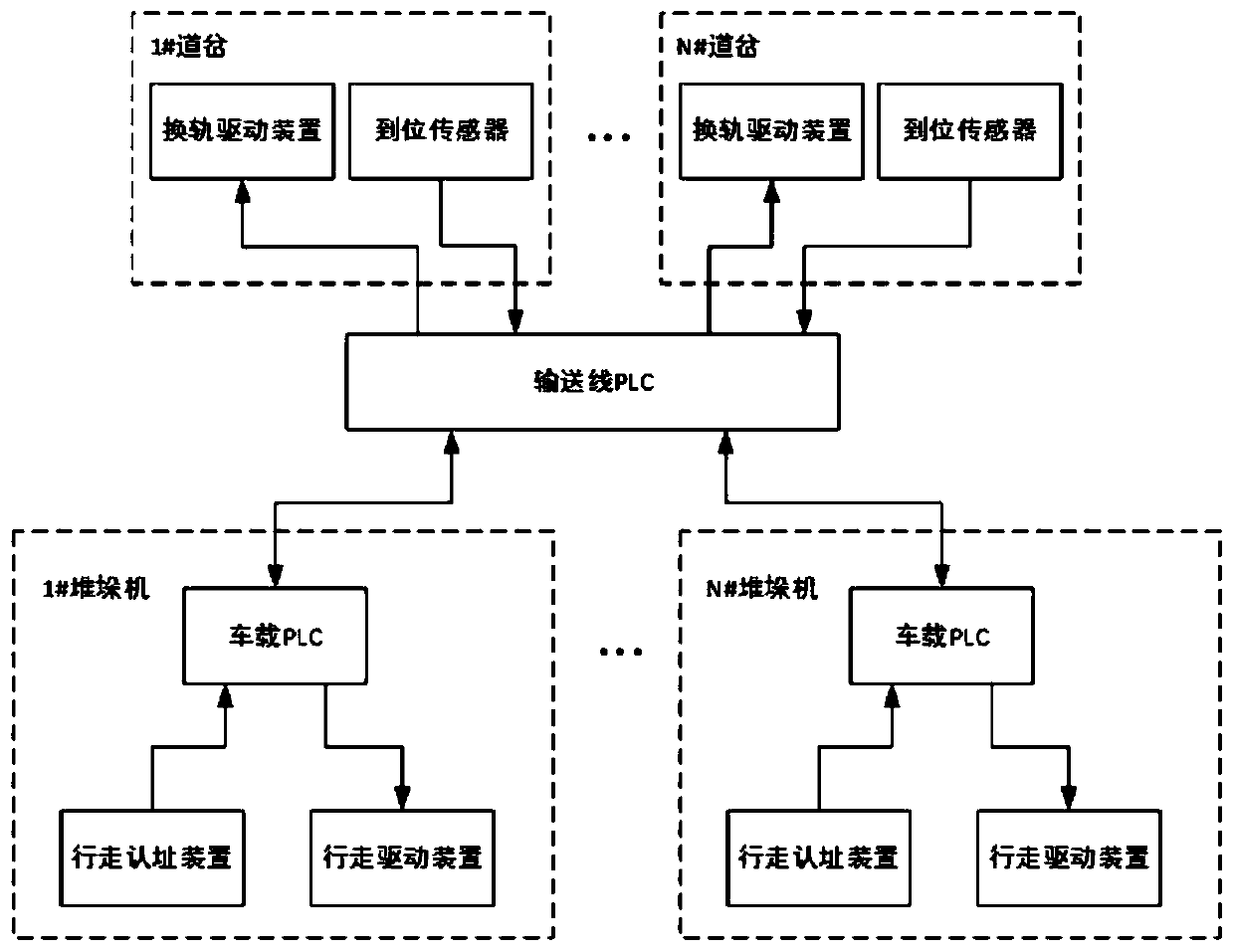

[0069] figure 1 A schematic diagram of the system hardware of the present invention is shown. The system consists of two parts: stacker equipment and turnout equipment. The stacker equipment hardware includes vehicle-mounted PLC, walking address recognition device, and walking driving device; the hardware of turnout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com