Shock absorbing shaft seat device for motor suspension

A shock-absorbing shaft and vertical shock-absorbing technology, applied in electromechanical devices, transmission devices driven by motors, springs/shock absorbers, etc., can solve the problem of increasing inspection frequency, reducing the stability and reliability of linear motor installation, increasing Maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

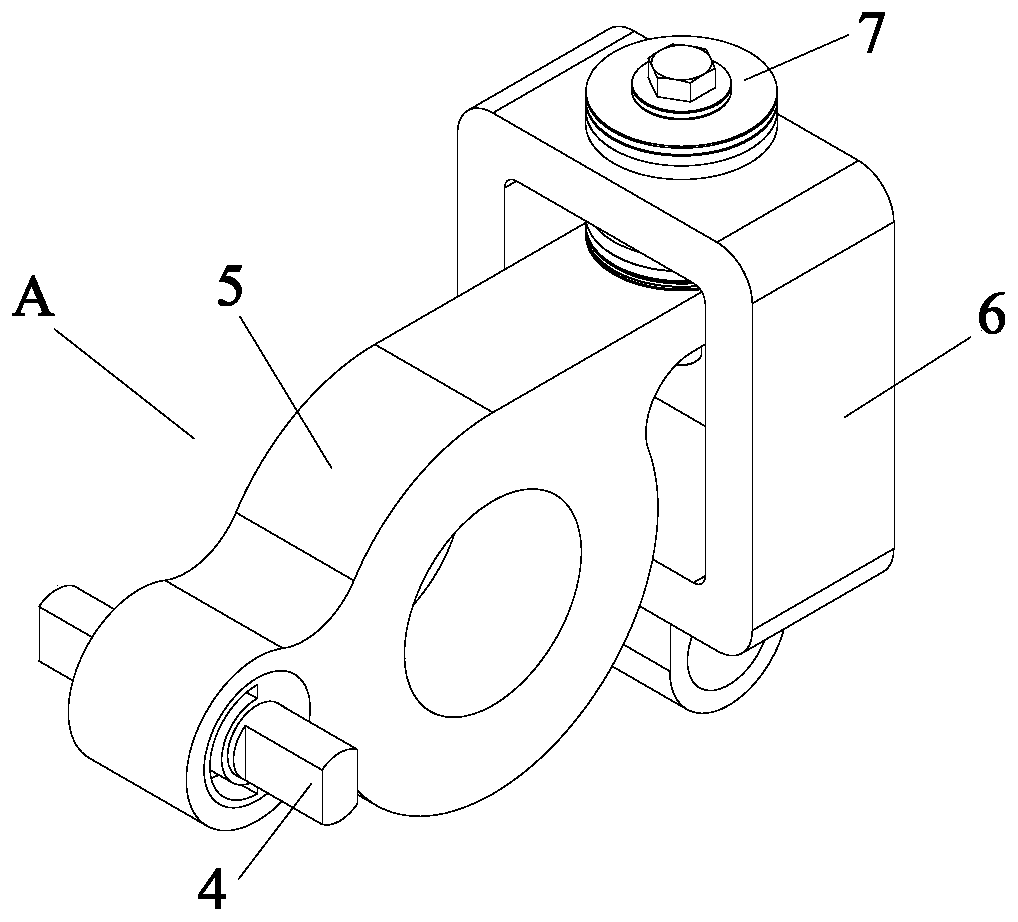

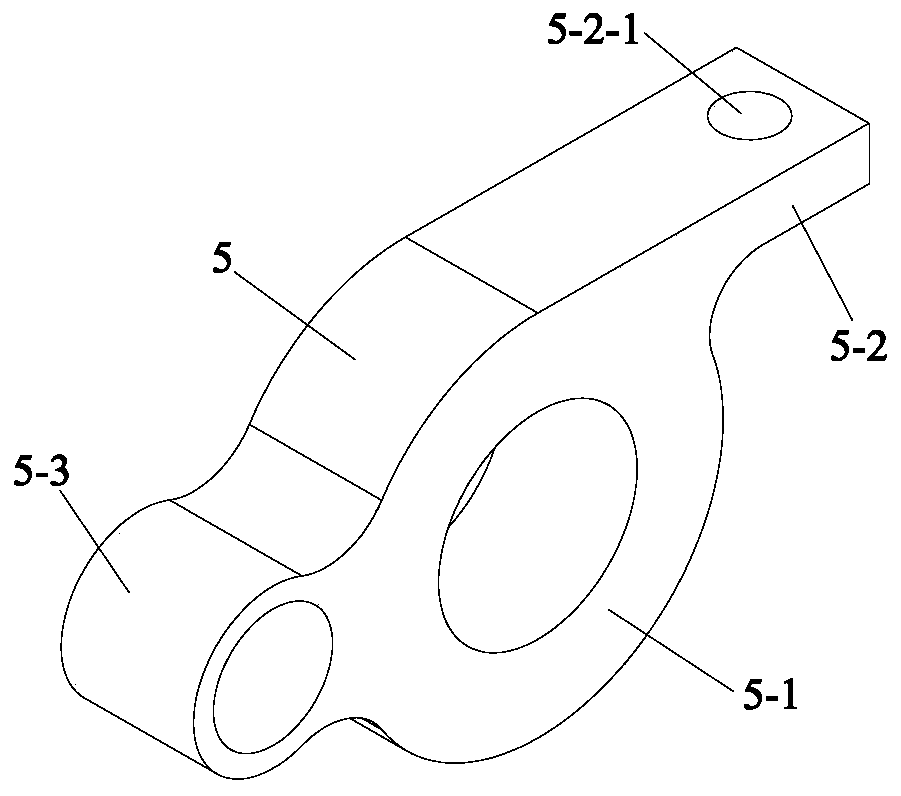

[0034] like Figure 1 to Figure 11 As shown, the shock-absorbing shaft seat device for motor suspension of the present invention includes a rubber node 4 as a horizontal elastic shaft part, an eccentric wheel axle sleeve 5, a vertical bearing suspension 6 and a vertical shock-absorbing pin mechanism 7, and the eccentric The wheel axle sleeve seat 5 includes an integrally formed axle sleeve 5-1, a bearing hanger connecting plate 5-2 and a rubber node sleeve 5-3, and the bearing hanger connecting plate 5-2 is along the tangent line of the outer diameter of the axle sleeve 5-1. The direction is connected with it, and the far end of the bearing hanger connecting plate 5-2 is provided with a vertical connecting plate through hole 5-2-1, and the axis of the connecting plate through hole 5-2-1 is aligned with the axis of the axle sleeve 5-1. The different planes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com