Settlement rectifying and integral lifting method for ballastless track using series pipeline grouting technology

A technology of ballastless track and grouting, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of good and bad lifting effect, large deviation of grouting parameters, and poor stability, so as to achieve the lifting effect Good, simple and fast construction, high lifting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

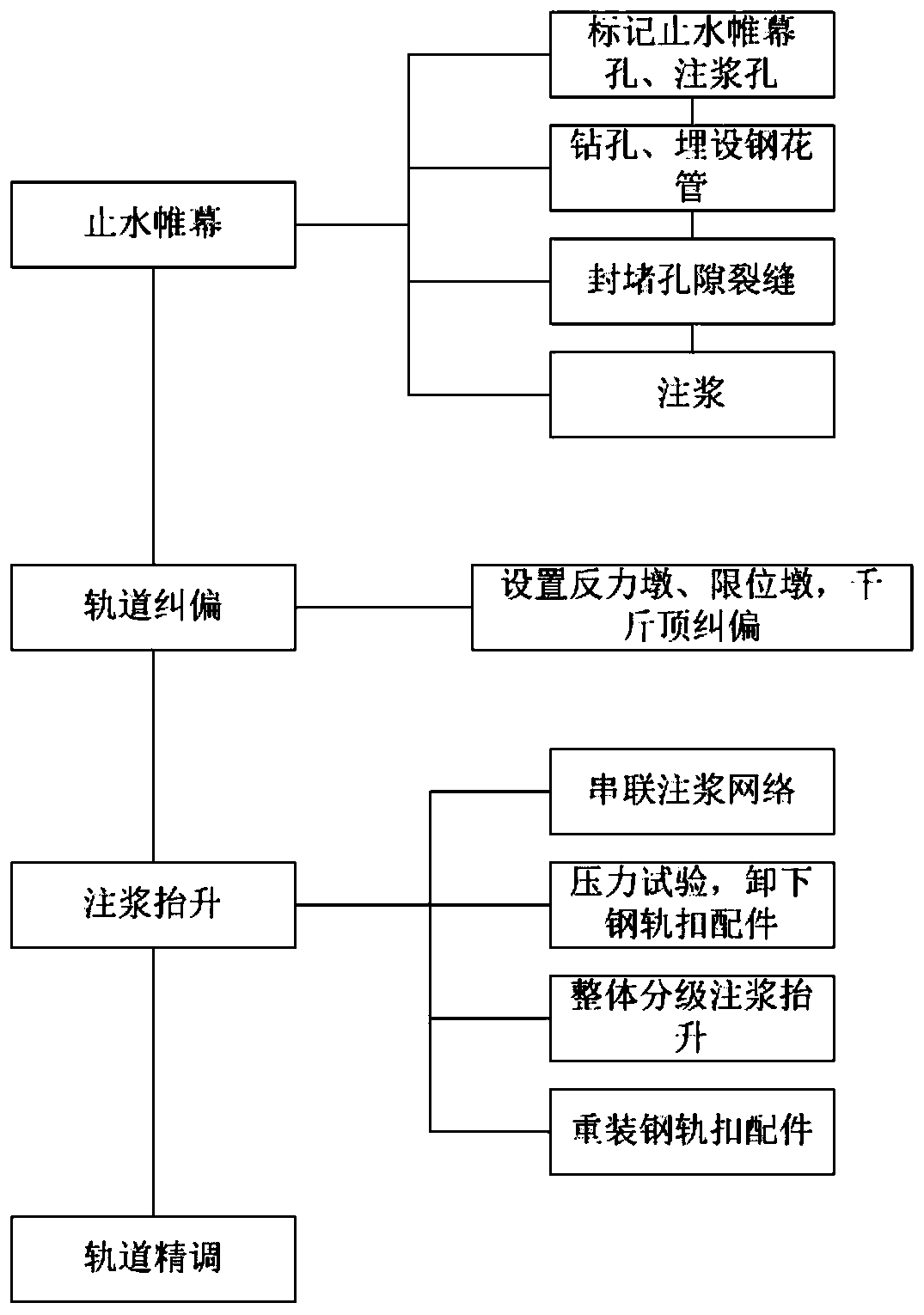

[0041] Such as Figure 1-4 As shown, the overall lifting method for ballastless track settlement correction using series pipeline grouting technology provided in this embodiment includes the following steps:

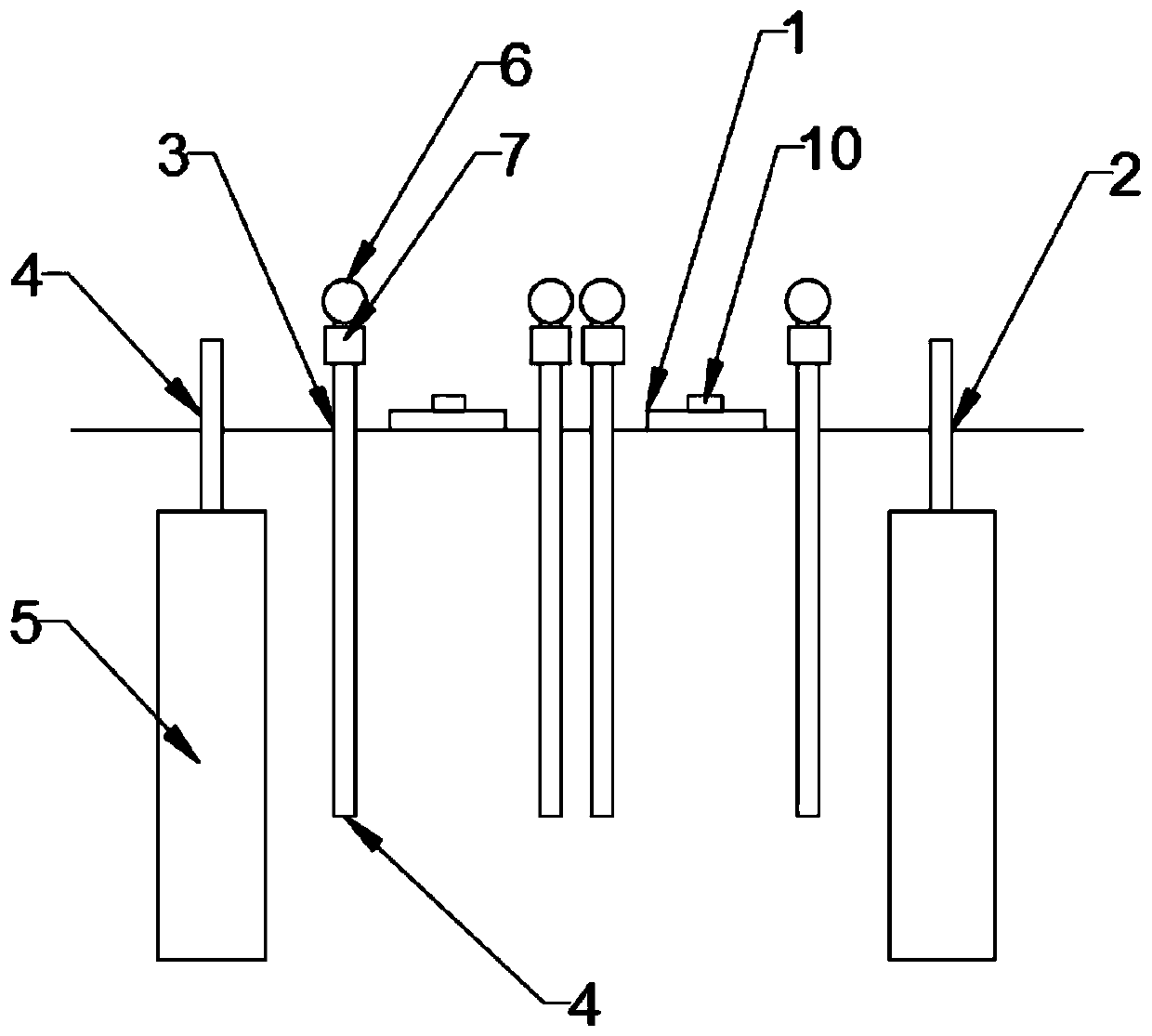

[0042] S1. Mark one water-stop curtain hole 2 along the rail direction on the outer side of the two rails 1, and mark 2 grouting holes 3 along the rail 1 direction on the inner side of the two rails 1. In the water-stop curtain hole 2 Mark a grouting hole 3 along the direction of the track 1 between the track 1 on the same side; drill a hole at the mark of the water-stop curtain hole 2 and the grouting hole 3 and bury the steel flower tube 4 vertically; the water-stop curtain The hole diameter of hole 2 and grouting hole 3 is 50mm, the hole distance is 800mm, and the hole depth is 2000mm. The actual drilled hole depth is 0.1m deeper than the designed hole. After the drilled hole meets the above-mentioned parameters, continue to drill steadily for 2 minutes. The purpose of ...

Embodiment 2

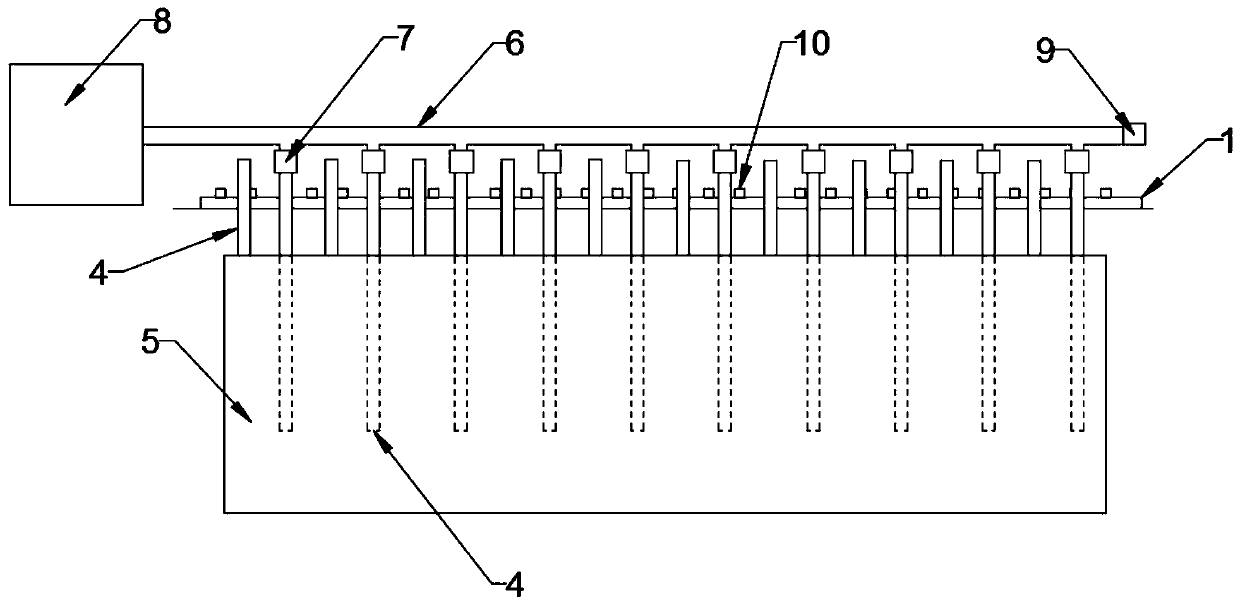

[0058] Such as Figure 5 As shown, the ballastless track settlement rectification and overall uplift method provided by this embodiment using the grouting technology in series uses a slightly different grouting network compared to Embodiment 1, specifically: 4 grouting holes 3 The corresponding steel flower tube 4 is connected with a steel tube 6 to form a complete series grouting network, and the end of the steel tube 6 is provided with an overflow valve 9.

[0059] In the tandem grouting network of this embodiment, the steel flower pipes corresponding to the four grouting holes are connected by the same steel pipe to form a complete steel pipe. In order to meet the requirements of simultaneous grouting of all steel flower pipes at the same pressure, all steel flower pipes should be closed first. On the upper valve, the second grouting pump injects grout into the steel pipe, and the grout flows out from the overflow valve along the steel pipe; when the grouting pressure of the se...

Embodiment 3

[0061] Such as Image 6 As shown, the ballastless track settlement rectification and overall lifting method using the serial pipeline grouting technology provided by this embodiment is different from the embodiment 2 as follows: There are a total of 3 marks on the inner side of the two tracks 1 along the direction of the track 1. Road grouting hole 3. The structure of the tandem grouting network in this embodiment is still similar to that of Embodiment 2. That is, the steel pipes 4 corresponding to the five grouting holes 3 are connected with the same steel pipe 6 to form a complete tandem grouting network. There is an overflow valve 9 at the end.

[0062] In the tandem grouting network of this embodiment, the steel flower pipes corresponding to the four grouting holes are connected by the same steel pipe to form a complete steel pipe. In order to meet the requirements of simultaneous grouting of all steel flower pipes at the same pressure, all steel flower pipes should be closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com