Environment-friendly microporous brick prepared by comprehensive utilization of solid wastes and preparation method of environment-friendly microporous brick

A solid waste and environmental protection technology, applied in applications, household appliances, clay products, etc., can solve the problems of heavy weight, high energy consumption and low utilization rate of microporous bricks, reducing energy consumption, reducing self-weight, ensuring The effect of sintering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

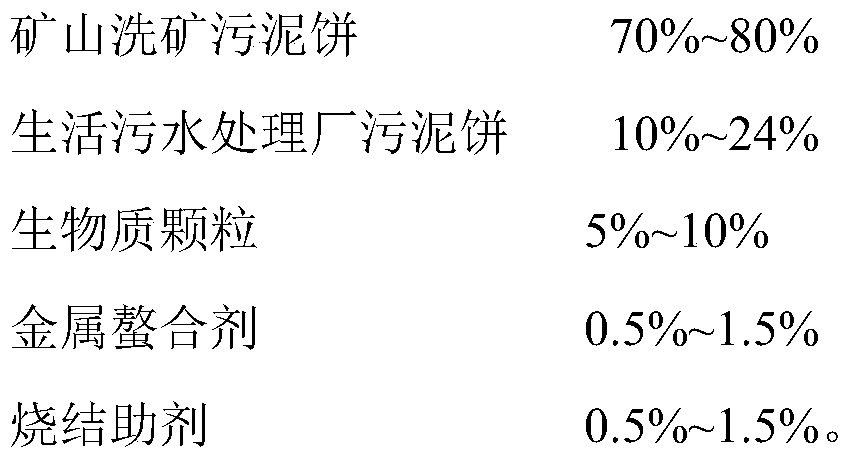

[0074] An environmentally friendly microporous brick prepared by comprehensive utilization of solid waste, which includes the following raw materials in weight percentage:

[0075]

[0076] Among them, biomass particles are made of crop straw.

[0077] Wherein, the crop straw is one or a combination of any two or more of corn straw, wheat straw, rice straw, cotton straw, soybean straw or sorghum straw.

[0078] Wherein, the metal chelating agent is polyacrylic acid.

[0079] Wherein, the sintering aid is one of aluminum oxide, zinc oxide or magnesium fluoride or a combination of any two or more.

[0080] The above-mentioned preparation method of an environmentally friendly microporous brick prepared by comprehensive utilization of solid waste comprises the following steps:

[0081] The first step, mine washing sludge pretreatment:

[0082] Step 1. Centrifugal separation: Centrifuge the mine washing sludge to separate sand and stones with a certain particle size to obtain...

Embodiment 2

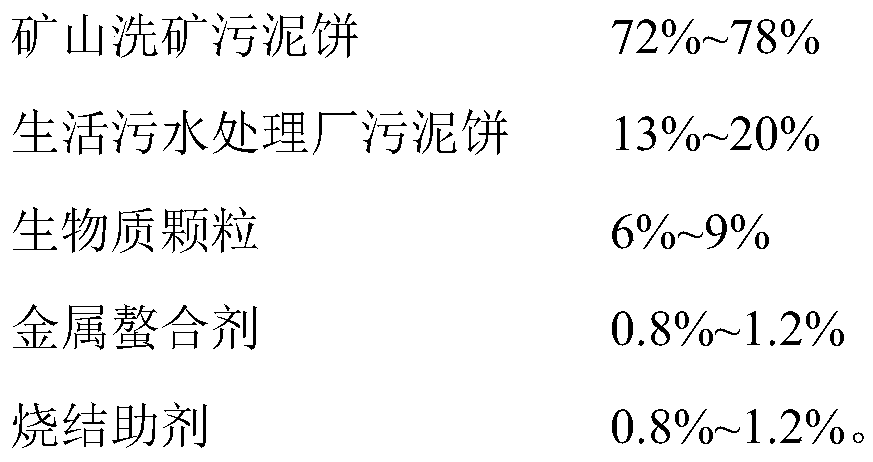

[0103] An environmentally friendly microporous brick prepared by comprehensive utilization of solid waste, which includes the following raw materials in weight percentage:

[0104]

[0105] Among them, biomass particles are made of crop straw.

[0106] In this embodiment, the crop straw is a combination of corn straw, wheat straw, rice straw, cotton straw, soybean straw and sorghum straw.

[0107] Wherein, the metal chelating agent is polyacrylic acid.

[0108] Among them, the sintering aid is magnesium fluoride.

[0109] The above-mentioned preparation method of an environmentally friendly microporous brick prepared by comprehensive utilization of solid waste comprises the following steps:

[0110] The first step, mine washing sludge pretreatment:

[0111] Step 1. Centrifugal separation: pump the mine washing sludge into a rotary bucket centrifuge for centrifugal separation, so as to separate the sand with a particle size of more than 1mm, and obtain the mine washing slud...

Embodiment 3

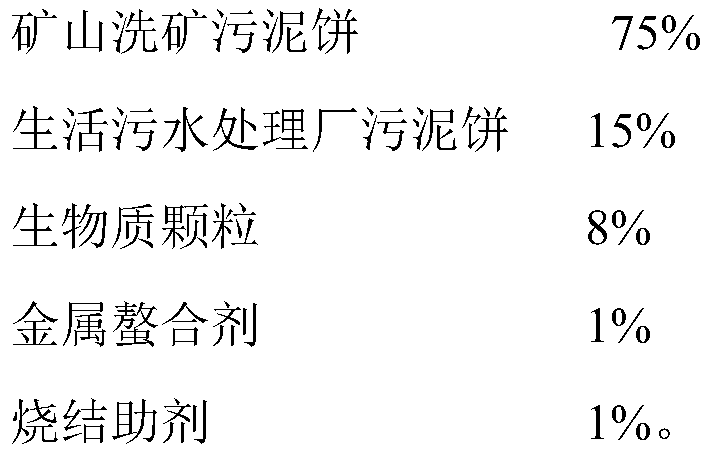

[0132] An environmentally friendly microporous brick prepared by comprehensive utilization of solid waste, which includes the following raw materials in weight percentage:

[0133]

[0134] Among them, biomass particles are made of crop straw.

[0135] In this embodiment, the crop stalks are corn stalks.

[0136] Wherein, the metal chelating agent is polyacrylic acid.

[0137] Wherein, the sintering aid is a combination of aluminum oxide and zinc oxide.

[0138] The above-mentioned preparation method of an environmentally friendly microporous brick prepared by comprehensive utilization of solid waste comprises the following steps:

[0139] The first step, mine washing sludge pretreatment:

[0140] Step 1. Centrifugal separation: pump the mine washing sludge into a rotary bucket centrifuge for centrifugal separation, so as to separate the sand with a particle size of more than 1mm, and obtain the mine washing sludge slurry;

[0141] Step 2. Storage and homogenization: In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com