Manufacturing method of sand-fixed painting

A production method and technology of sand painting, applied in the field of sand painting culture, can solve the problems that cannot be preserved permanently for appreciation, and achieve the effect of improving art appreciation and preservation, good qualitative effect, and perfect expression details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

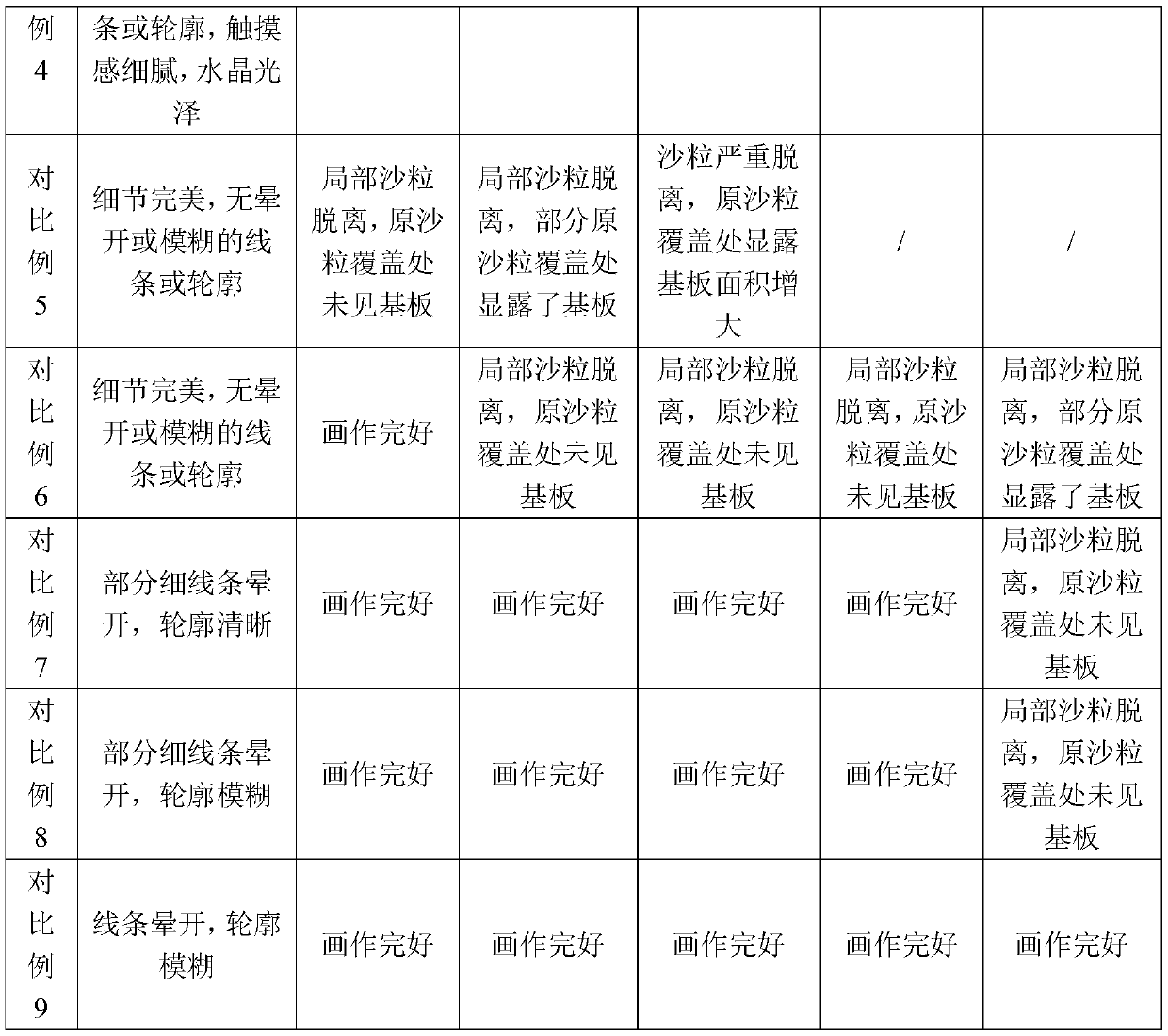

Examples

Embodiment 1

[0017] Select the porcelain plate as the substrate, wipe the surface of the substrate clean with alcohol, mix sand and rubber powder at a mass ratio of sand: rubber powder = 1:1.8 to form mixed sand, and use the mixed sand to paint on the surface of the clean substrate;

[0018] 2) Bake the painted substrate in an environment of 140±10°C for 10 minutes. After the baking is completed, take it out and cool it down, and mount it into a sand solid painting.

Embodiment 2

[0020] Select a diatom mud board (with a surface roughness of 1.3) as the substrate, wipe the surface of the substrate clean with alcohol, mix sand and rubber powder with a mass ratio of sand: rubber powder = 1:1.8 to form a mixed sand, and use a mixing Sand painting on the clean substrate surface;

[0021] 2) Bake the painted substrate in an environment of 140±10°C for 10 minutes. After the baking is completed, take it out and cool it down, and mount it into a sand solid painting.

Embodiment 3

[0023] Select the bamboo charcoal board as the substrate, wipe the surface of the substrate clean with alcohol, mix sand and rubber powder at a ratio of sand: rubber powder = 1:1.8 to form mixed sand evenly, and use the mixed sand to paint on the surface of the clean substrate;

[0024] 2) Bake the painted substrate in an environment of 140±10°C for 10 minutes. After the baking is completed, take it out and cool it down, and mount it into a sand solid painting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com