Locking control method and device of steelmaking desulphurization molten iron tipping vehicle

A locking device, a technology for desulfurized molten iron, which is applied in the direction of manufacturing tools, casting melt containers, metal processing equipment, etc., and can solve problems such as easily damaged locking equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

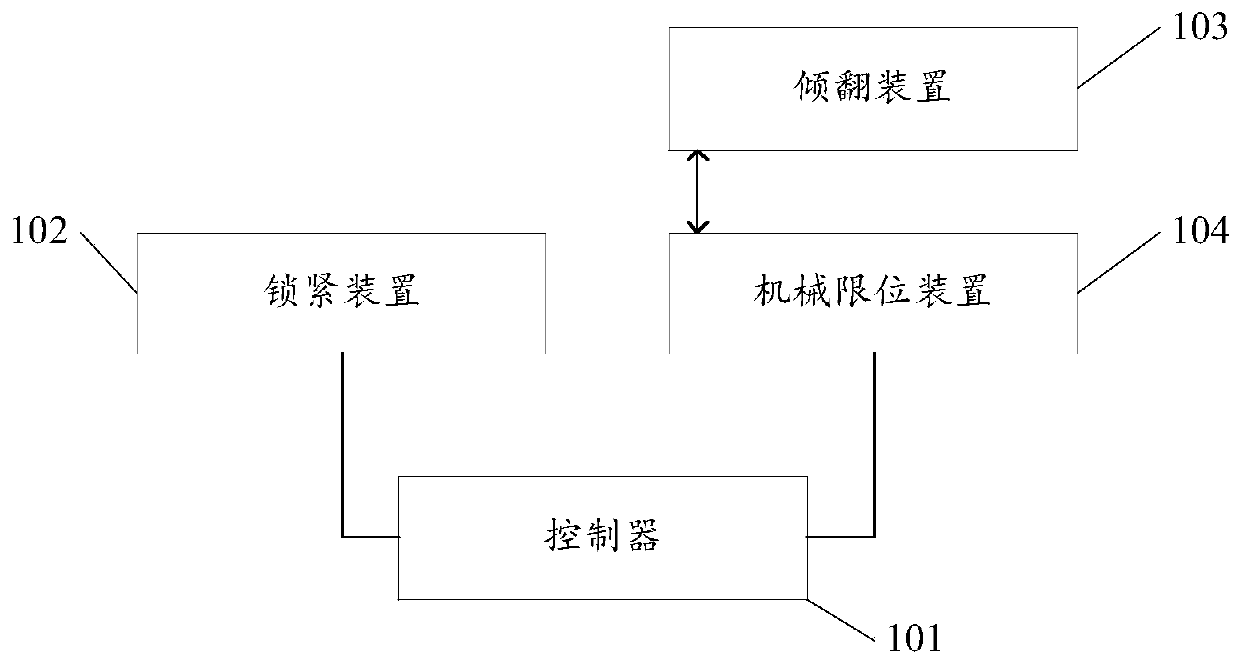

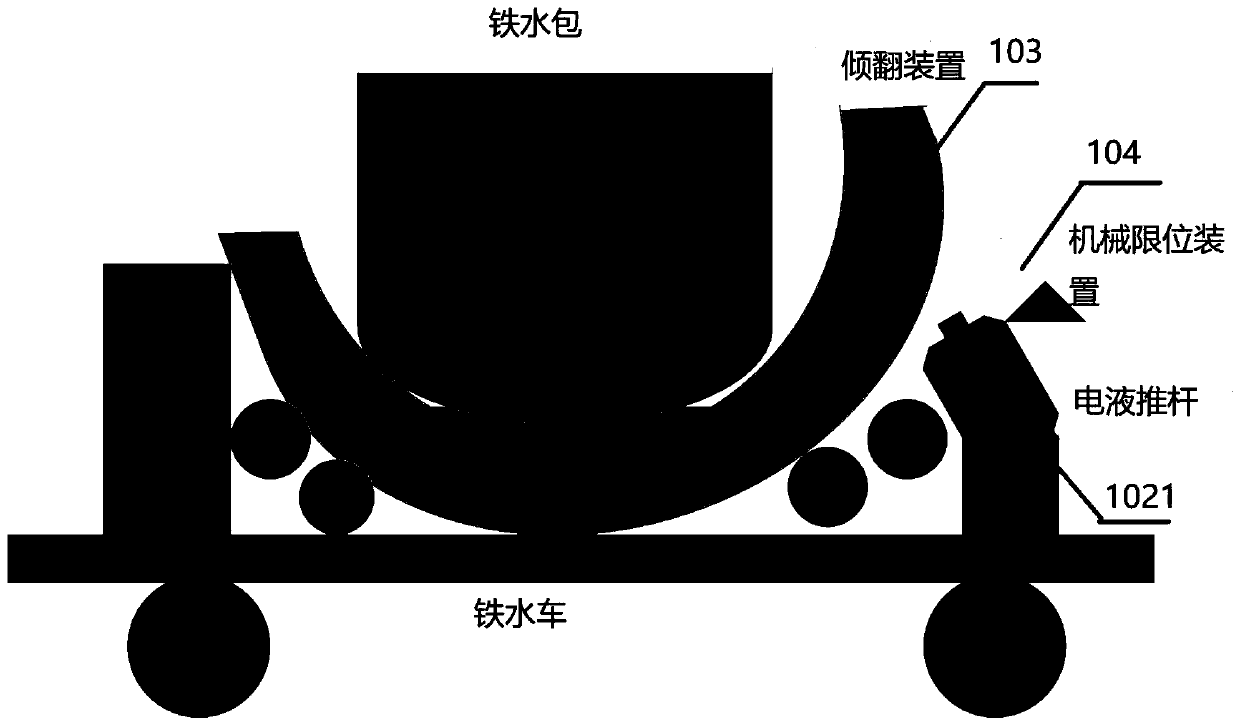

[0045] An embodiment of the present invention provides a locking control device for a steelmaking desulfurization molten iron tipping car, such as figure 1 As shown, it includes: a controller 101 , a locking device 102 , a tipping device 103 , and a mechanical limit device 104 , wherein the controller 101 is connected to the locking device 102 and the mechanical limit device 103 .

[0046] Wherein, the tilting device 103 is used to carry the ladle. When the tilting device is vertically placed, the molten iron can be placed horizontally, and when the tilting device is rotated, the molten iron can be tilted.

[0047] The locking device 102 is used to start operation and point to the tipping device 103 based on the locking command;

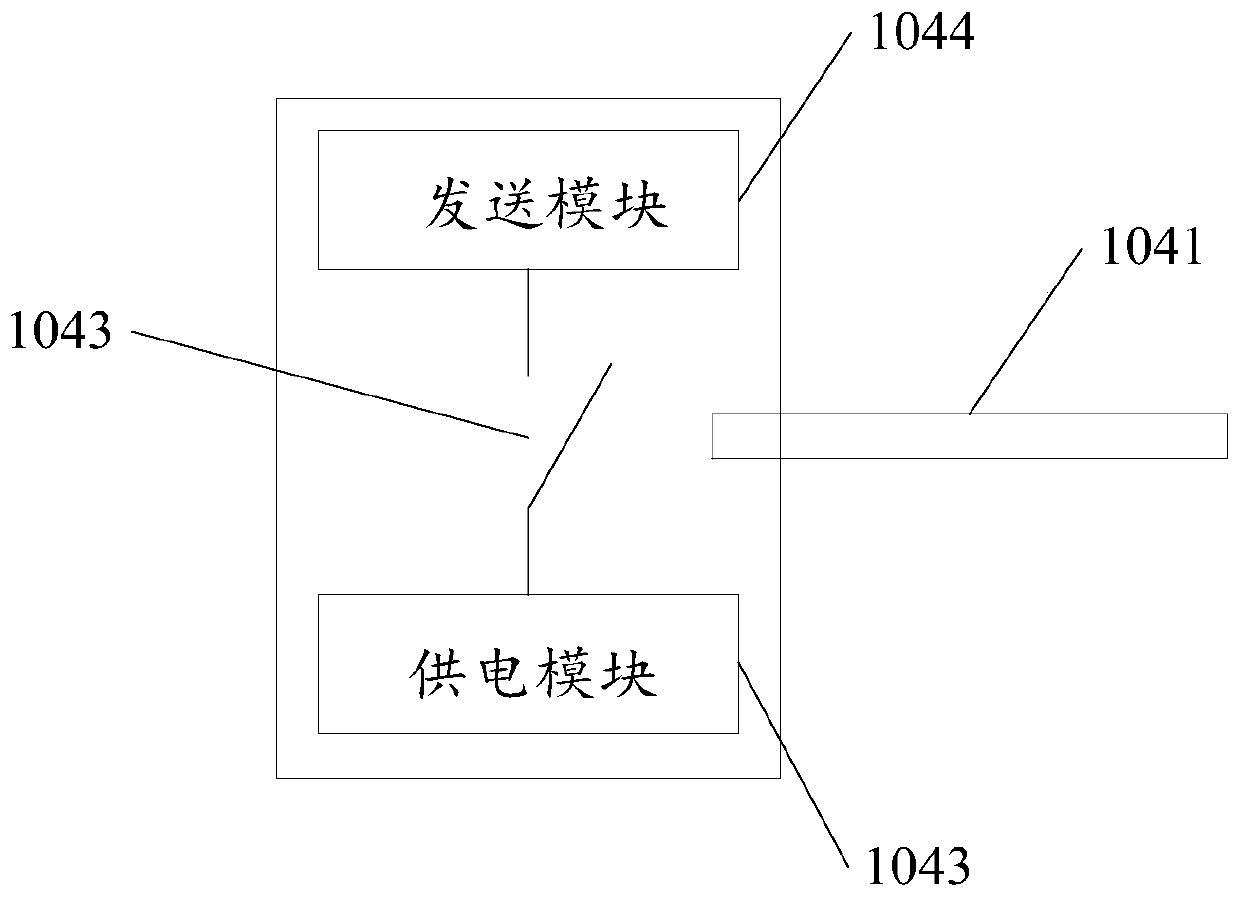

[0048] The mechanical limit device 104 is used to generate a limit pulse signal and feed it back to the controller 101 when it is detected that the locking device 102 has moved to a preset limit;

[0049] The controller 101 is used to control the lo...

Embodiment 2

[0066] Based on the same inventive concept, an embodiment of the present invention also provides a locking control method for a steelmaking desulfurization molten iron tipping car, which is applied to a locking control device for a steelmaking desulfurization tipping car. The device includes: a controller, a locking device, tipping device, mechanical limit device, such as Figure 4 Shown: includes:

[0067] S401, generating a locking instruction;

[0068] S402. Based on the locking instruction, control the locking device to operate and point to the tilting device;

[0069] S403. Receive a limit pulse signal, where the limit pulse signal is specifically a limit pulse signal generated when the mechanical limit device detects that the locking device has moved to a preset limit;

[0070] S404. Based on the actual effective duration of the limit pulse signal, control the locking device to run in reverse for a preset duration on the falling edge of the limit pulse signal and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com