A high-efficiency mixing and batching device for lithium battery production

A lithium battery and high-efficiency technology, which is applied to mixers with rotary stirring devices, mixer accessories, non-aqueous electrolyte batteries, etc., can solve problems such as imperfect structure, inconvenience for efficient and sufficient fusion of lithium battery ingredients, and inconvenience for mixing barrels to shake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

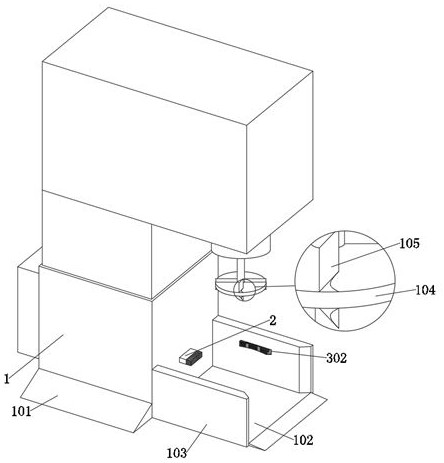

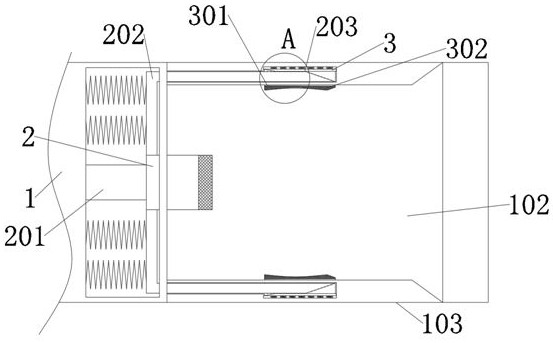

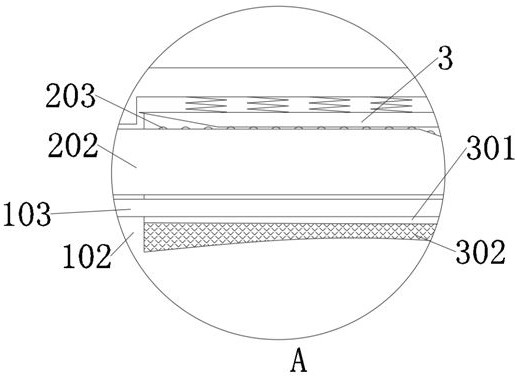

[0027] as attached figure 1 To attach Image 6 Shown:

[0028] The present invention provides a high-efficiency stirring and batching device for lithium battery production, including a main body 1, a side piece 101, a bottom plate 102, a side plate 103, a rotating piece 104, an auxiliary piece 105, a force block 2, an insertion rod 201, a side rod 202, Contact wheel 203, force plate 3, moving part 301, clamping part 302, mixing chamber 4, bottom rod 401, telescopic rod 402 and rotating plate 403; the main body 1 is a rectangular structure, and the two sides of the main body 1 are provided with wedge-shaped The side member 101 of the structure, moreover, the right end bottom two sides of main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com