Medical adhesive applicator

A technology of applicators and adhesives, which is applied in medical containers, medical packaging, and medical devices, etc., can solve the problems of inefficient use and complicated operation of medical adhesives, and achieve the effect of reducing the difficulty of crushing and increasing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

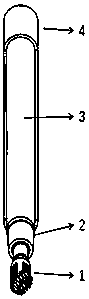

[0045] Embodiment 1: Extruder with triangular prism-shaped convex point in the middle

[0046] combine image 3 , Figure 13 In this embodiment, the outer diameter of one end of the bottle stopper 2 with the filter element 7 inside matches the inner diameter of the smear bottle 3, thereby connecting; the hollow part. In this way, the component connection of the applicator head 1, the bottle stopper 2 and the applicator bottle 3 is achieved, so as to realize the delivery of the glue from the storage part to the applicator part. The ampoule tube 8 is arranged in the internal storage part of the smear bottle 3, and the smear bottle 3 is fixed on the closed end of the bottom of the extruder 4 through a plug-in connection method. The entire device is thus completed with component connections.

[0047] combine Figure 4 , Figure 6, The extruder 4 of this embodiment has a length of 6.8cm, an inner diameter of the cylindrical part of 9.1mm, and an outer diameter of 10.8mm. The...

Embodiment 2

[0048] Example 2: Extruder with a conical convex point in the middle

[0049] combine Figure 7 , The extruder of this embodiment has a length of 6.8cm, an inner diameter of the cylindrical part of 9.1mm, and an outer diameter of 10.8mm. There are two raised points 9 and 10 inside the extruder, both of which are cones, wherein the diameter of the bottom surface of the cone is 3mm, the bottom angle is 60-80°, preferably 70°, and the raised point 10 is located The part of the card slot with a limit function set by the length is 4.6cm away from the bottom; the raised point 9 is located in the middle of the ampoule tube, 2.6cm away from the bottom, and the distance between the two raised points is 2cm. During use, the bottom of the ampoule tube is fixed on the extruder The closed end of the bottom, the middle part contacts the raised point 9, when the top of the ampoule tube is pressed, the raised point 8 acts as the fulcrum of the lever, and the closed end of the extruder acts a...

Embodiment 3

[0050] Example 3: Extruder with triangular prism-shaped convex points at the bottom

[0051] combine Figure 8 , The extruder of this embodiment has a length of 6.8cm, an inner diameter of the cylindrical part of 9.1mm, and an outer diameter of 10.8mm. There are two convex points 11 and 12 inside the extruder, both of which are triangular prisms with a height of 3mm, and the bottom is an equilateral triangle with a side length of 2-3mm. The part of the card slot with a limit function is 4.6cm away from the bottom; the raised point 11 is located at the bottom 1 / 3 of the ampoule tube, the distance between the raised point 11 and the raised point 12 is 3.1cm, and the distance between the raised point 11 and the closed end of the bottom of the extruder is 1.5cm , the closed end of the smear bottle attached with the ampoule tube is fixed on the closed end of the bottom of the extruder. Due to the support of the convex point 11 inside the extruder, the upper part of the ampoule tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com