Dental prosthesis

A technology of dentures and teeth, which is applied in the field of dentures, can solve problems such as low precision, and achieve the effects of low vibration, low disc height, and shortened milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

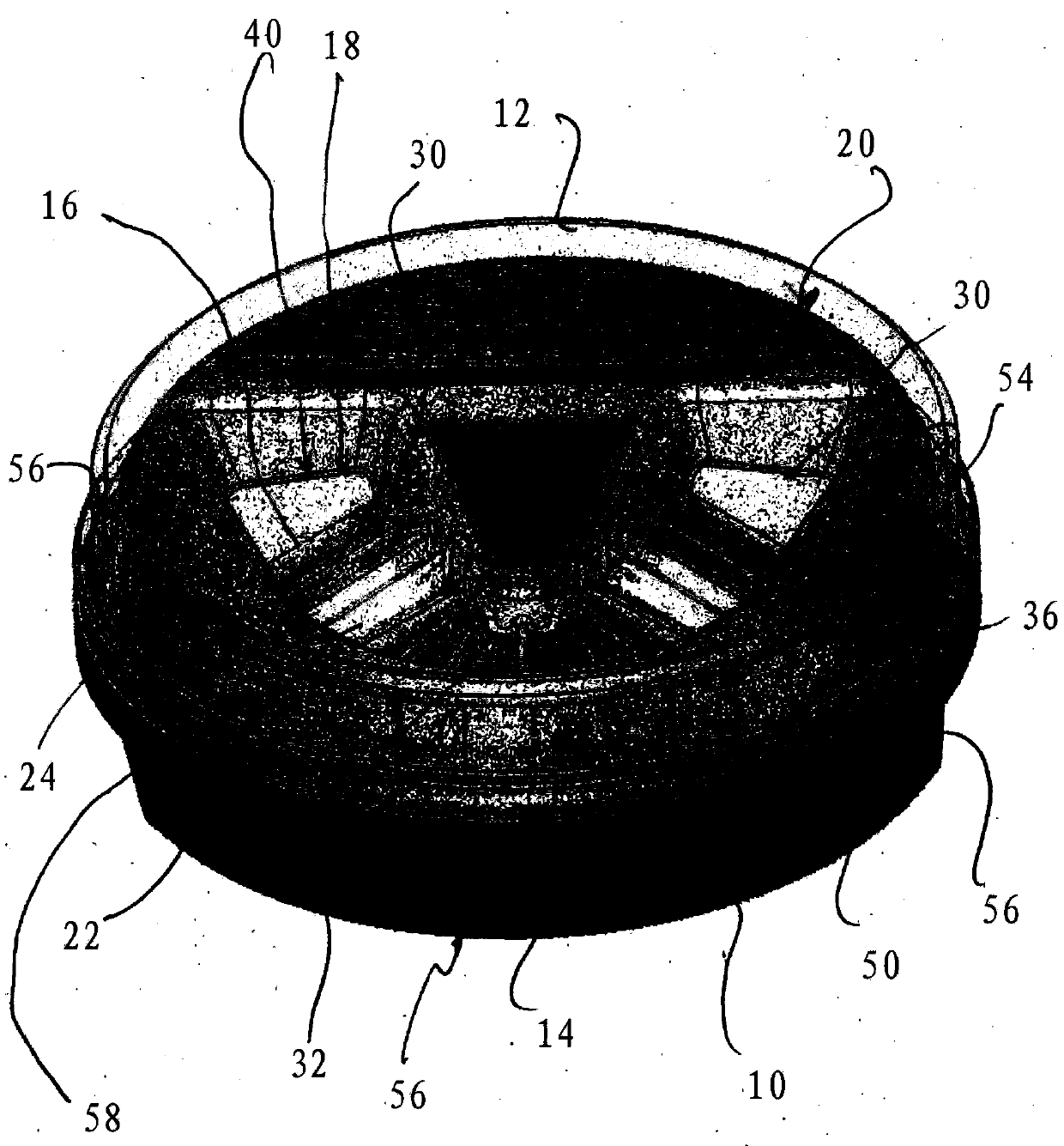

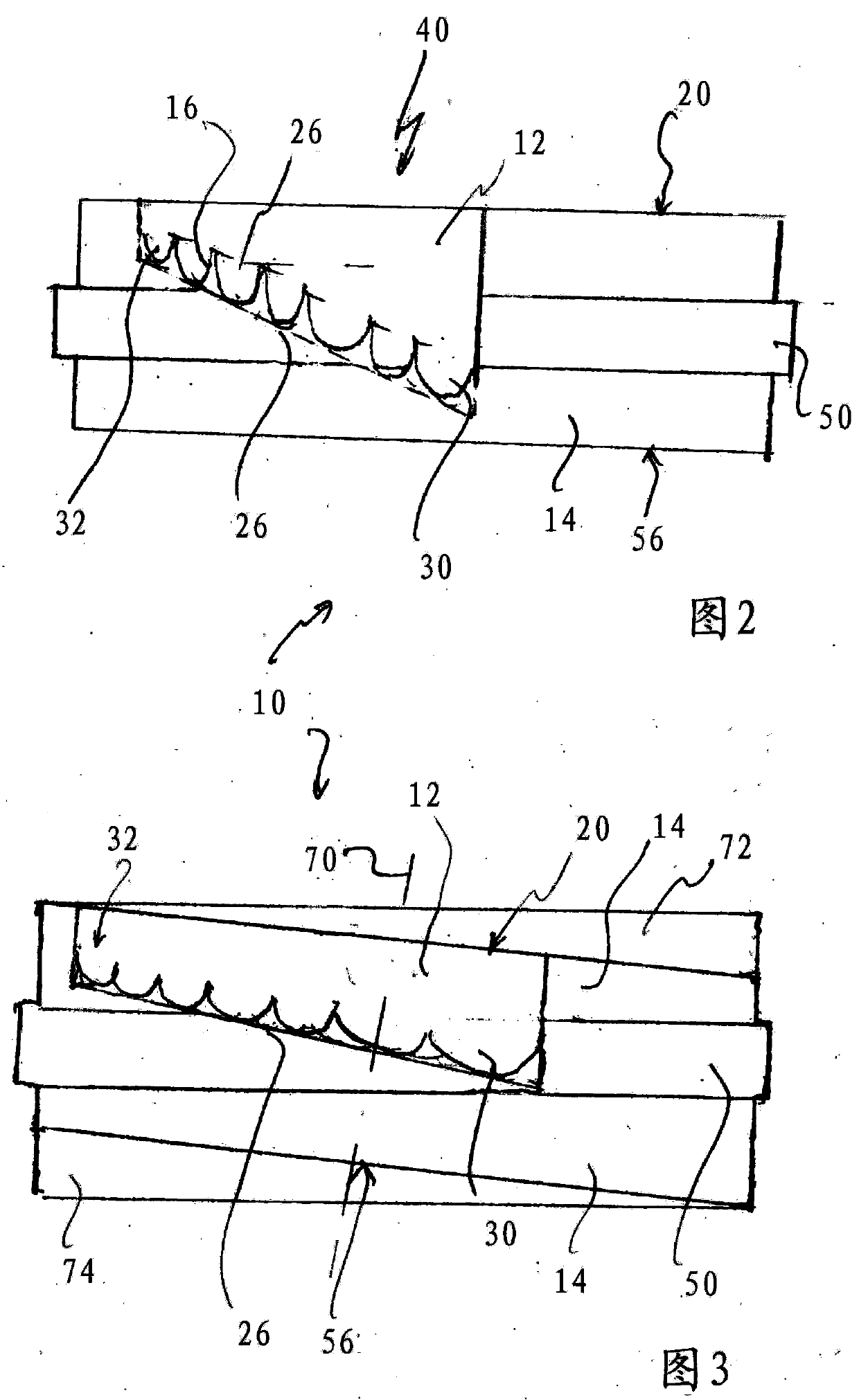

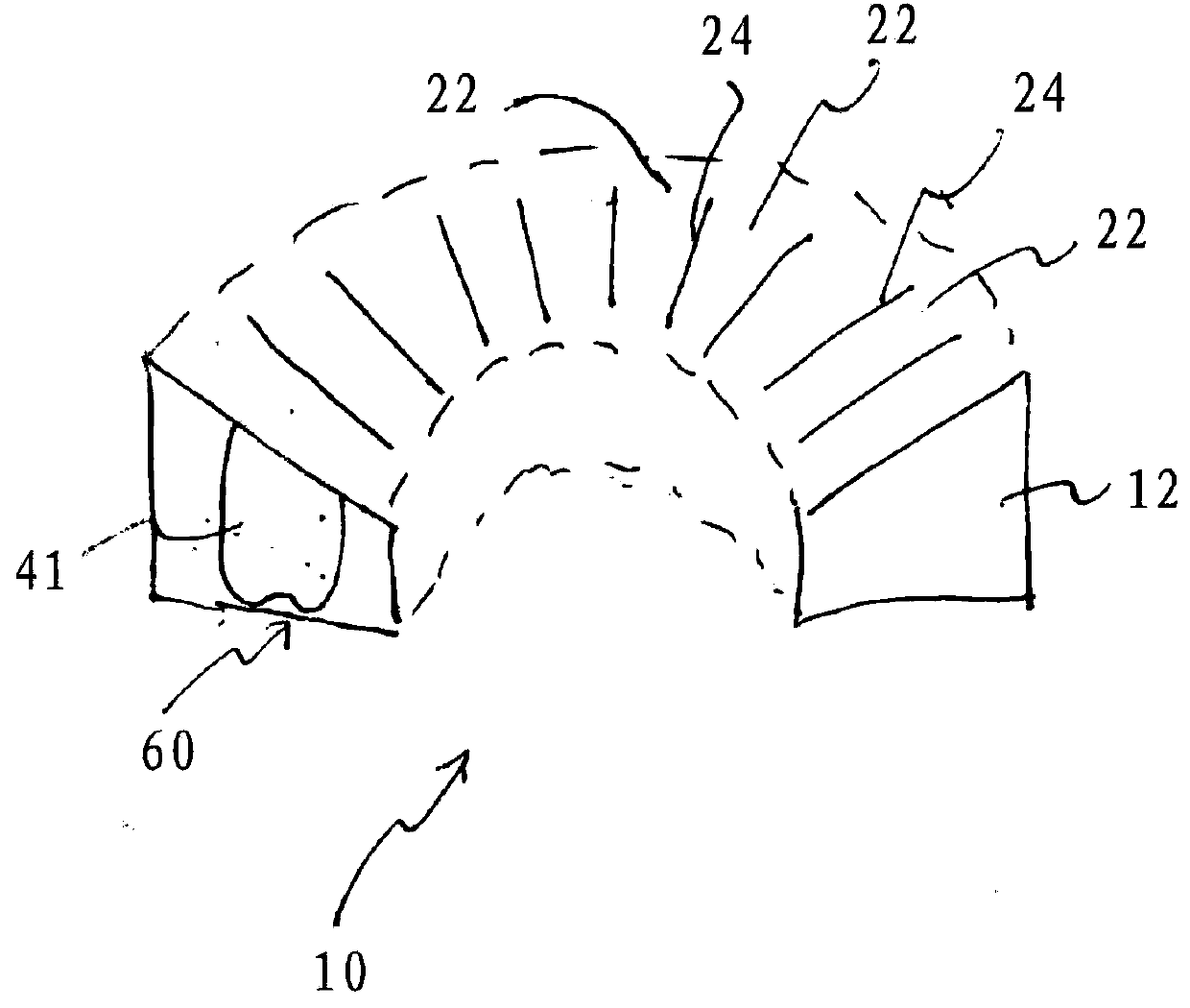

[0055] A blank 10 is shown, consisting of a tooth-colored material 12 and a flesh-colored material 14 . The blank was determined to be used in the manufacture of a mandibular denture.

[0056] The blank 10 is substantially disc-shaped. exist figure 1 The interface 16 between the tooth-colored material 12 and the flesh-colored material 14 can be seen in . The blank has specially shaped recesses 18 in the flesh-coloured material 14 . The material 12 extends from the upper side 20 of the blank 10 into the recess 18 .

[0057] The tooth-coloured material 14 of the blank 10 has a diameter or width greater than 5 cm, and in particular has a substantially flat cylindrical shape with a diameter / height ratio greater than 2:1, preferably greater than 3:1.

[0058] The flesh-colored and tooth-colored materials 14 and 12 are interconnected, for example, by bonding, by polymerization, and / or by integral fabrication.

[0059] Said recess has a substantially U-shaped shape with rather w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com