A food grouting machine

A grouting machine and grouting technology, which are applied in food science, dough cutting machinery, baking, etc., can solve the problems of difficult to guarantee uniform grouting amount, high equipment cost, inconsistent size, etc., to achieve uniform product size, avoid The effect of excessive residue and consistent grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

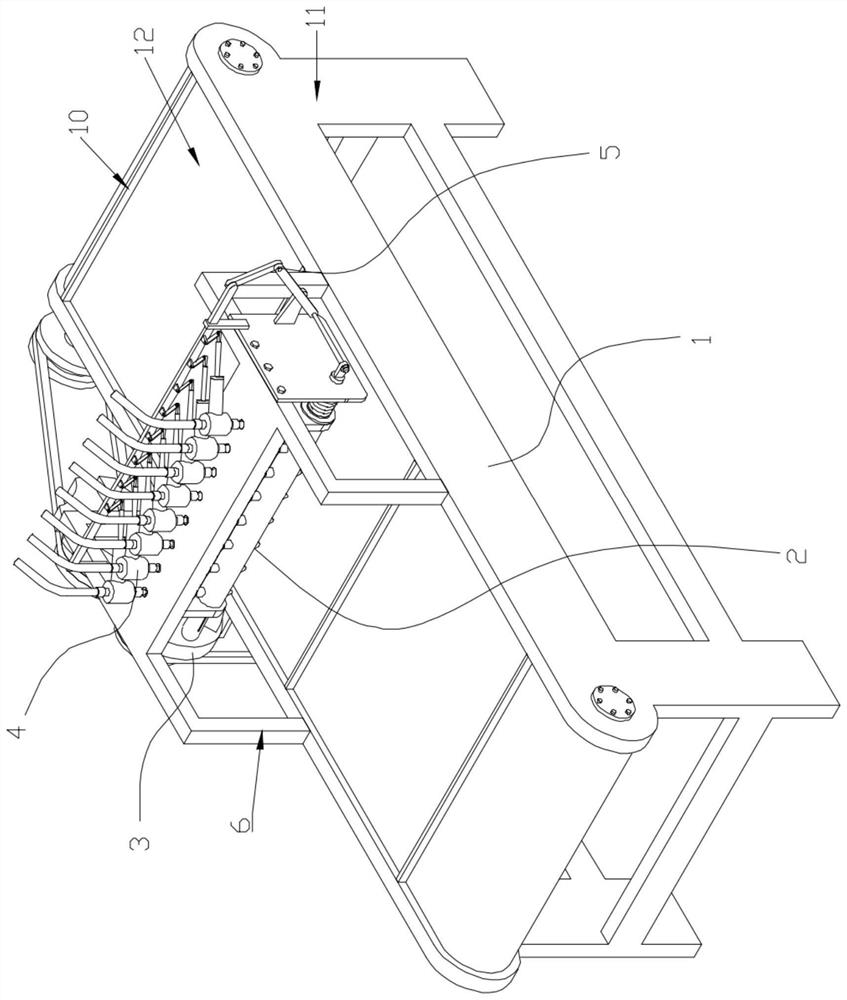

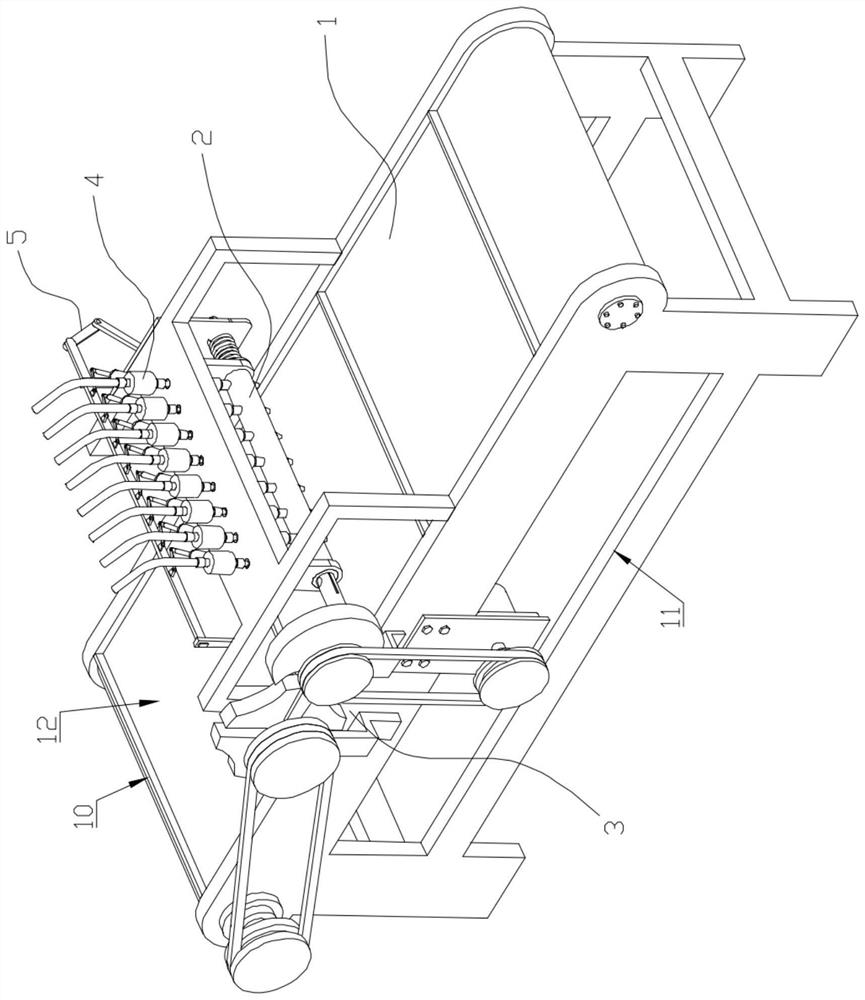

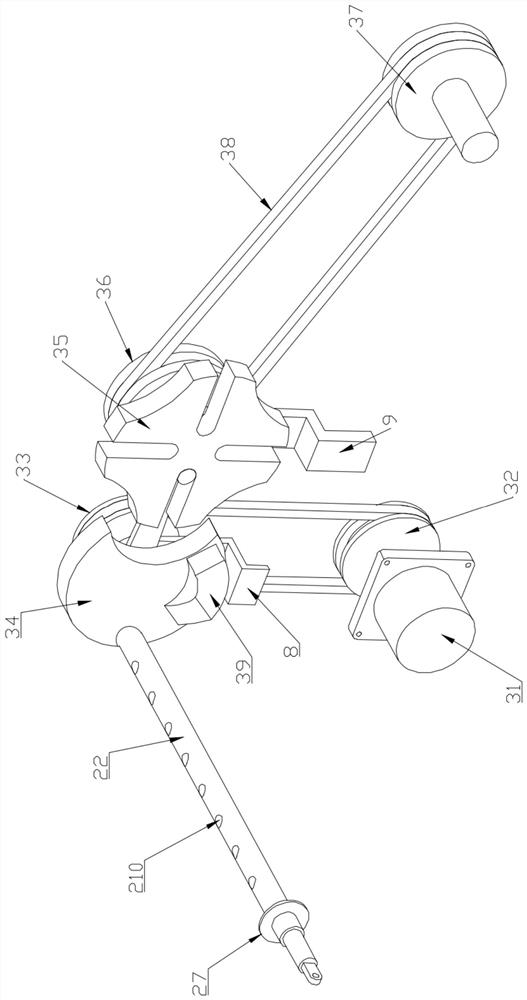

[0029] Figure 1 to Figure 10 It shows the structural form of the present invention in the case of non-grouting, a food grouting machine, including a conveying mechanism 1, a grouting assembly 2, a driving mechanism 3 and a grouting power mechanism 4, and the conveying mechanism 1 is used to convey products mold, the top of the conveying mechanism 1 is equipped with a frame 6, and the grouting assembly 2 is used to intermittently inject slurry into the product mold, and the grouting assembly 2 is installed on the support arm 11 connected to the frame 6 Below the frame 6, the driving mechanism 3 is installed on one side of the conveying mechanism 1. The driving mechanism 3 can not only drive the conveying mechanism 1 to convey the product mold step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com