Comprehensive monitoring method for well and ground combined coal-seam hard top plate segmented hydraulic fracturing

A hard roof and hydraulic fracturing technology, applied in the direction of applying stable tension/pressure to test material strength, geophysical measurement, measurement, etc., can solve problems such as the extension scale and distribution shape of cracks that cannot be fractured, and achieve Accurately evaluate fracturing effects, improve monitoring accuracy, and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

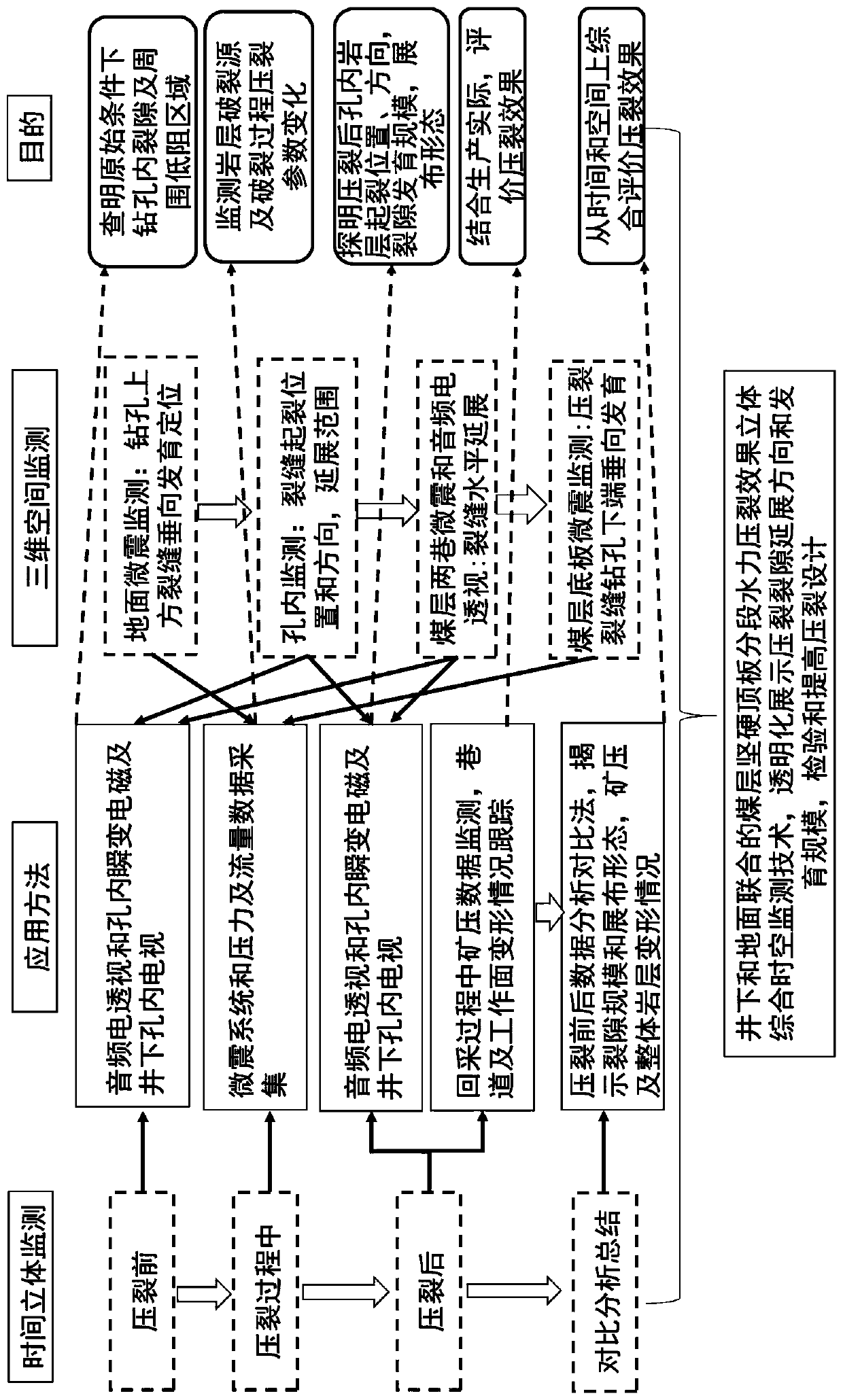

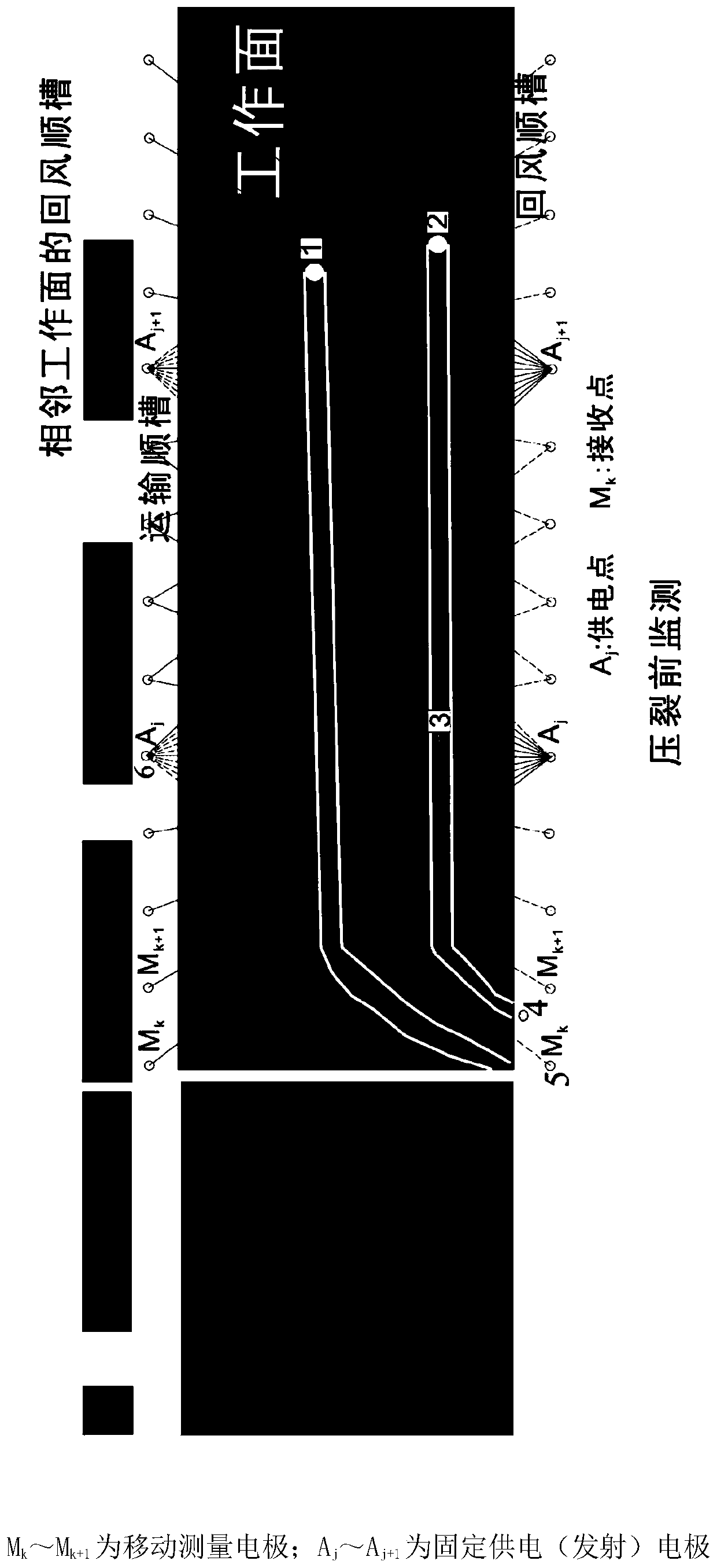

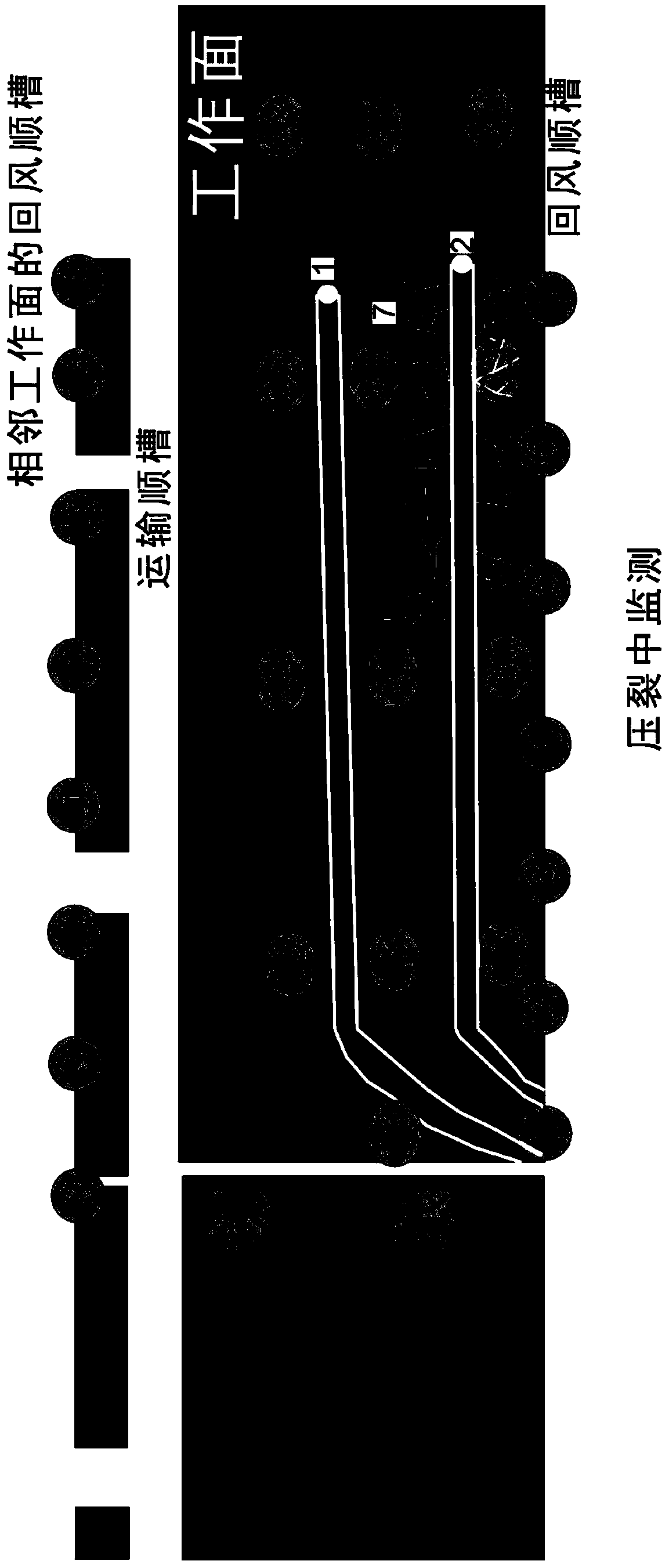

[0030] see Figure 1 to Figure 5 , which shows the comprehensive monitoring method for segmental hydraulic fracturing of coal seam hard roof combined with well and ground in the present invention.

[0031] The comprehensive monitoring method for the segmented hydraulic fracturing of the hard roof of the coal seam combined with the well and the ground brings together multiple monitoring methods such as audio-visual perspective, micro-seismic and downhole television, and comprehensive monitoring of the hard roof of the coal seam before, during and after the hydraulic fracturing , Through the combined three-dimensional analysis of the surface and downhole, three-dimensional space-time fracturing fracture monitoring can be achieved, the distribution shape and extension direction of fracturing fractures can be displayed transparently, and the fracturing weakening effect of hard roof can be accurately evaluated. It specifically includes the following steps (see figure 1 ):

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com