Track traversing fireproof rolling shutter and construction method thereof

A technology of fire shutter and construction method, which is applied in the direction of fire doors, building structures, building components, etc., and can solve the problem that fire shutters cannot be tightly closed, cannot meet the requirements of 3h fire barrier specifications, and cannot meet the fireproof and smoke-proof airtightness of fire barriers Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a track-passing fireproof shutter, specifically a track-passing fireproof shutter for trains or transfer cars in industrial plants, nuclear power plants, and spent fuel reprocessing facilities.

[0033] When the goods are transported by rail, and the transfer track needs to pass through fire barriers such as firewalls or plant boundaries, it is necessary to open a passage hole on the fire barrier, and add a fire shutter door that will automatically close when a fire occurs on the hole as a compensation measure for the fire barrier , at this time, it is necessary to adopt the fire shutter described in this embodiment.

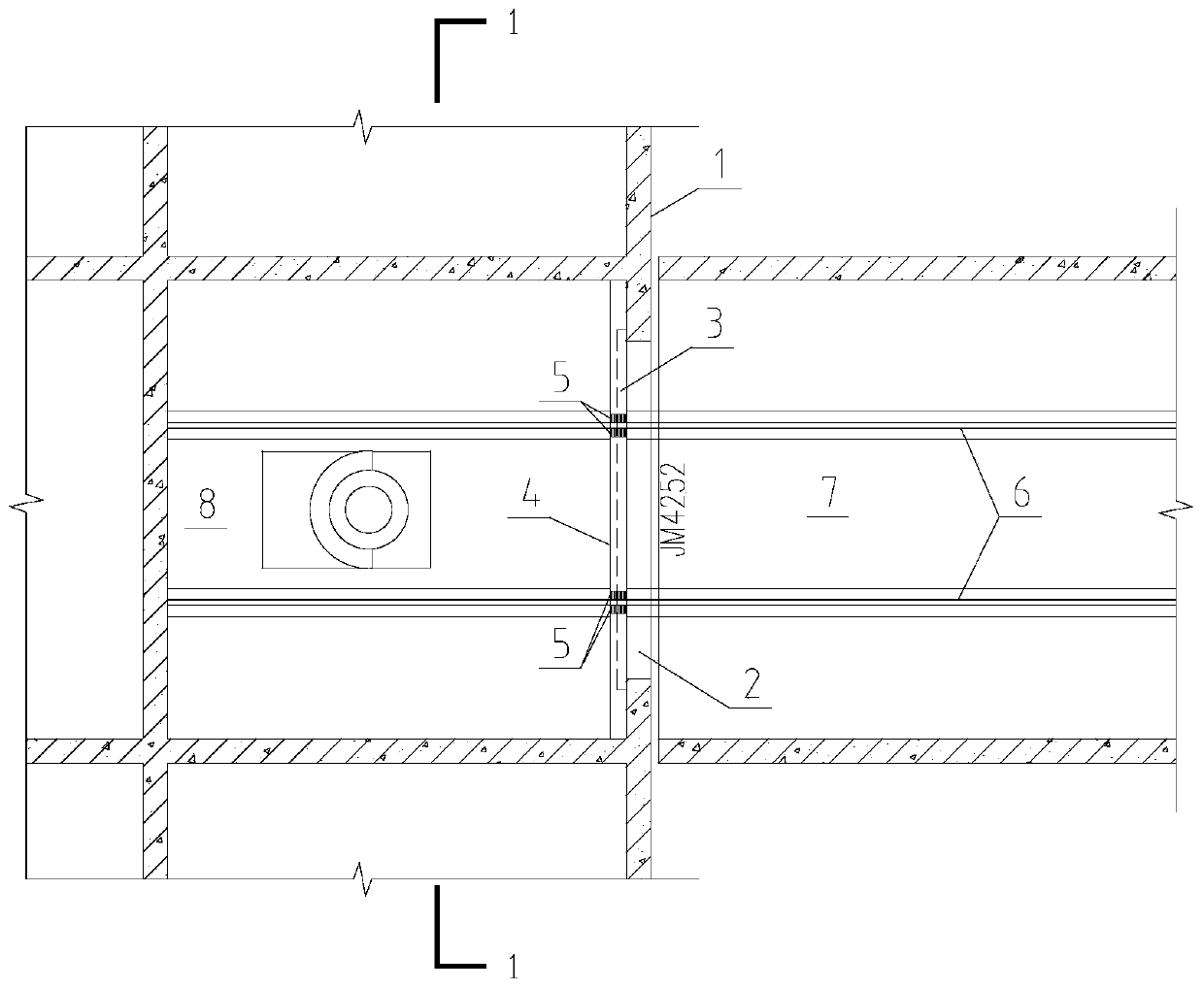

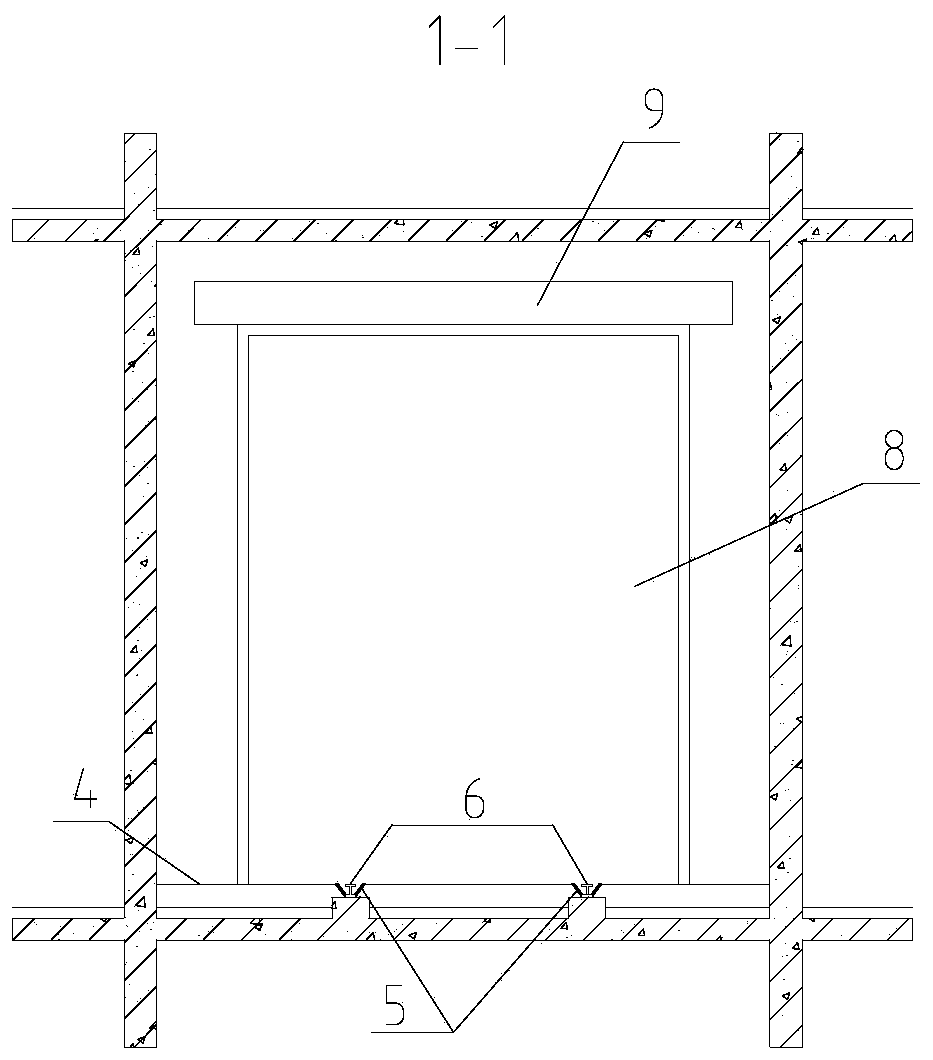

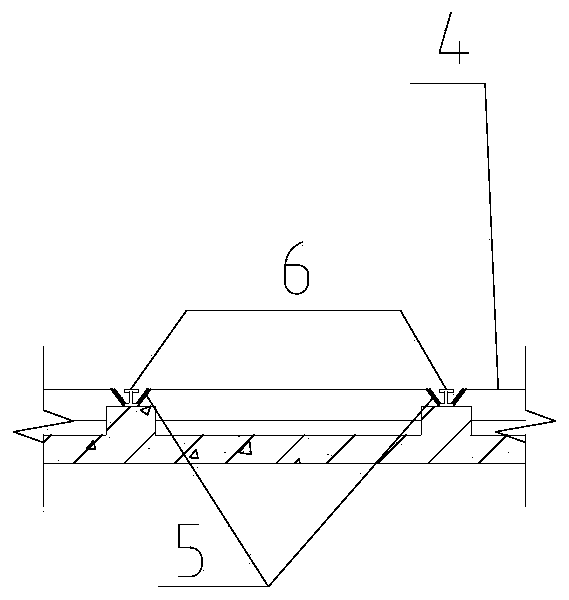

[0034] figure 1 shows a schematic plan view of the track passing through the fire shutter; figure 2 shows a schematic cross-sectional view of the track passing through the fire shutter, that is figure 1 Middle 1-1 profile; image 3 show figure 2 Partial enlarged node details in the middle. Such as Figure 1-3 As shown, the...

Embodiment 2

[0050] This embodiment provides a method for constructing a rail-passing fire shutter, specifically a method for constructing a rail-passing fire shutter for trains or transfer cars in industrial plants, nuclear power plants, and spent fuel reprocessing facilities.

[0051] Such as Figure 4 As shown, the construction method includes the following steps S101 to S104.

[0052] S101. Install a fire shutter door at the passage opening opened on the fire barrier;

[0053] S102. Set a threshold on the ground directly below the fire shutter door;

[0054] S103. Set a gap corresponding to the passage width of the vehicle at the position where the track crosses on the threshold;

[0055] S104. Install a fireproof expansion sealing strip in the gap.

[0056] Among them, the main raw material of the fireproof expansion sealing strip is expandable graphite, also known as flexible graphite. Expandable graphite is made of natural flake graphite through chemical treatment, and it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com