Multi-stage rolling rice milling process

A rolling type, rice flour technology, applied in the direction of grain processing, etc., can solve the problems of low milling efficiency, inconvenient feeding and discharging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

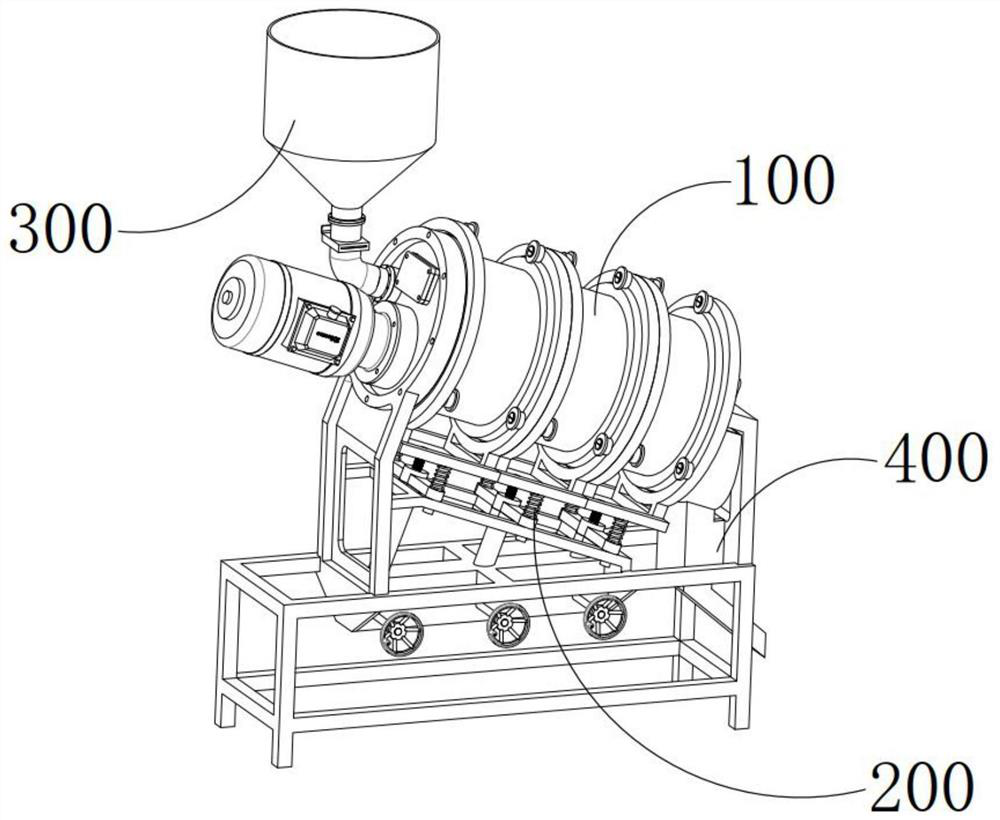

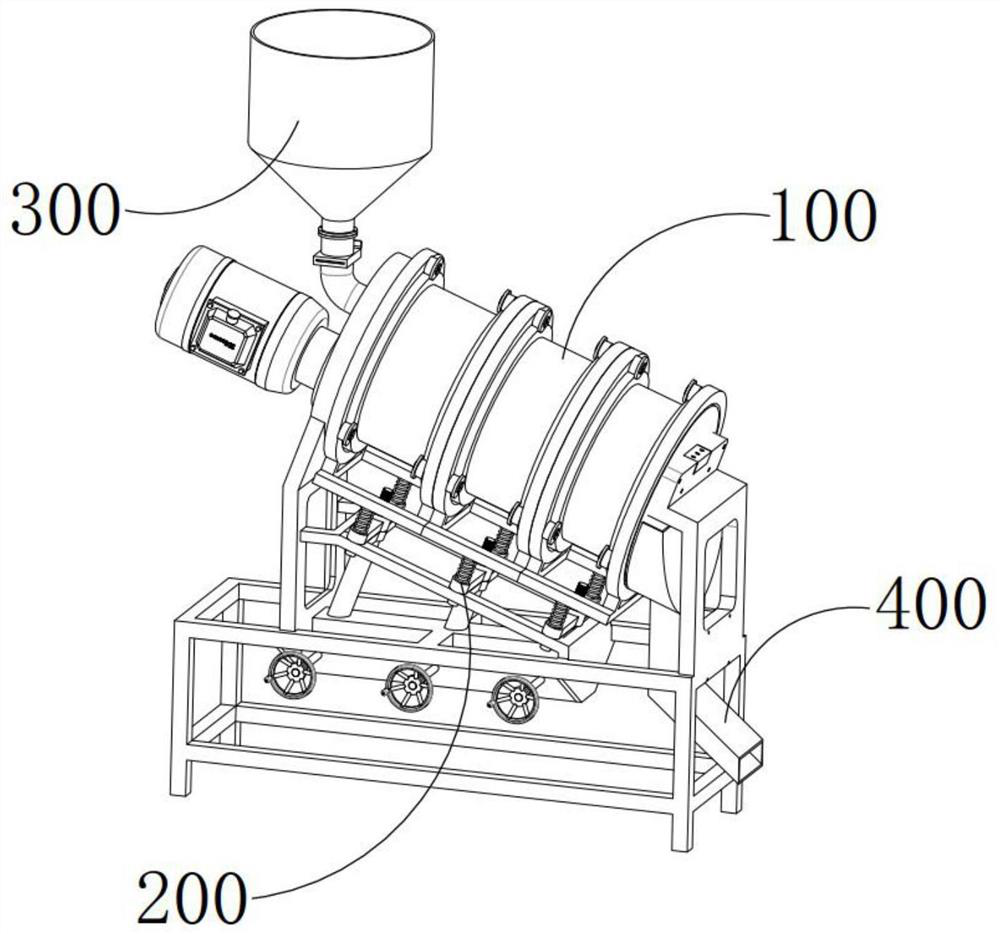

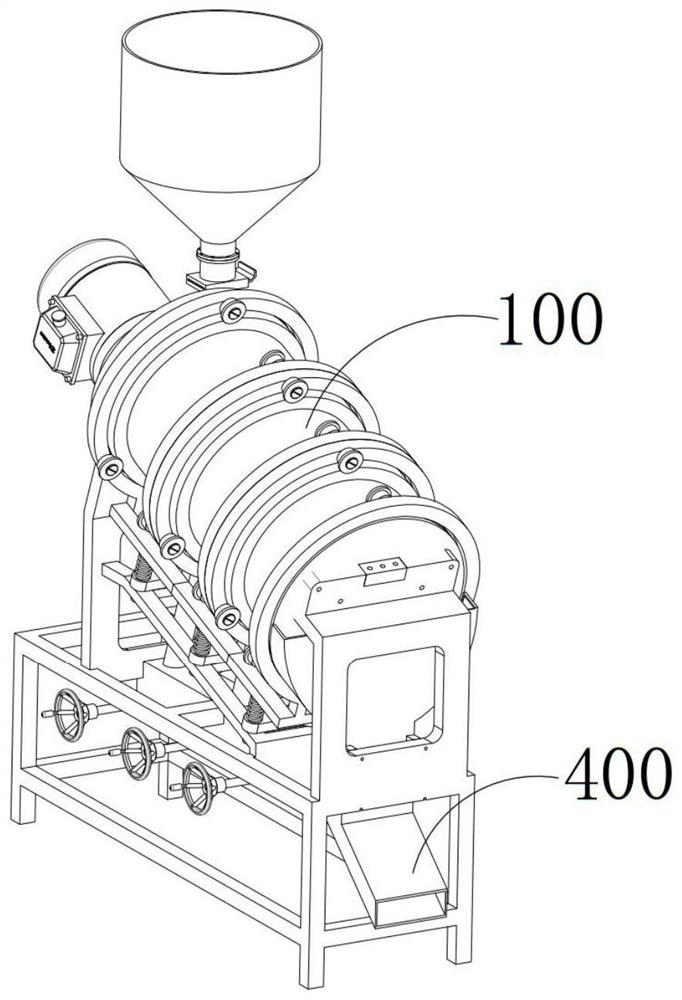

Image

Examples

Embodiment Construction

[0063] Multistage rolling type rice milling process, its steps are:

[0064] (1) Feeding stage;

[0065] S1: The user puts rice into the funnel 301 of the feeding part 300, pulls the gate 303 out of the gate and switches the connecting channel 302 from blocking to conducting, and the rice enters the rolling device through the connecting channel under its own gravity 100 input terminals;

[0066] The rolling device 100 includes a floor-standing mounting frame 101, the top of the mounting frame 101 is supported with inclined mounting plate one 102 and inclined mounting plate two 103 arranged in parallel with each other and the height of the first mounting plate 102 is greater than the height of the second mounting plate 103 , the end surface of the first mounting plate 102 close to the second mounting plate 103 is fixedly provided with a circular fixed plate 104 parallel to the plane where it is located, and the circular fixed plate 104 parallel to the plane where it is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com