Auxiliary tools for particle size adjustment devices and particle size adjustment systems

A technology of adjusting device and auxiliary tool, applied in the field of auxiliary tool and particle size adjustment system, can solve problems such as unfavorable work efficiency and complicated operation mode, and achieve the effects of improving labor efficiency, simplifying operation mode and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

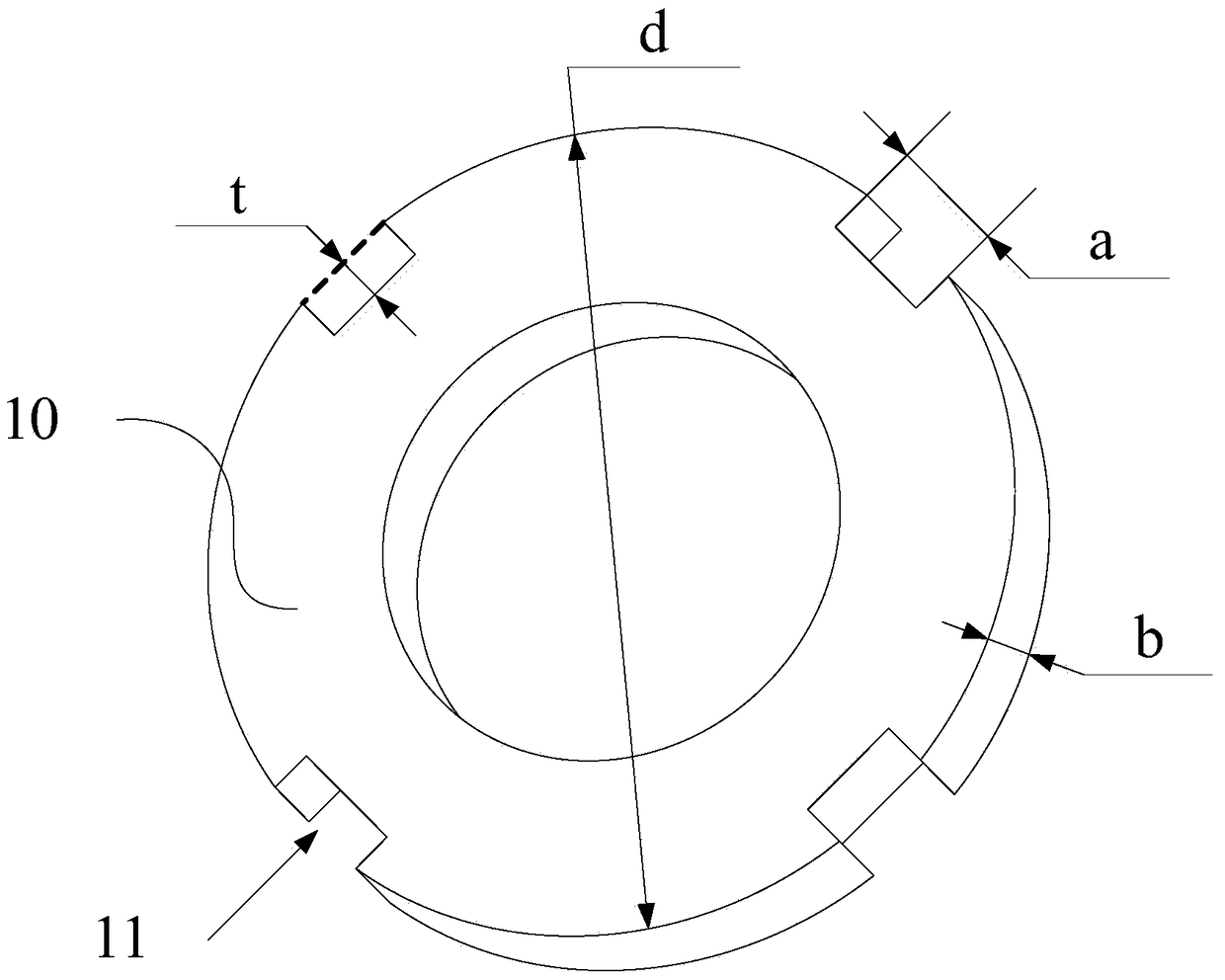

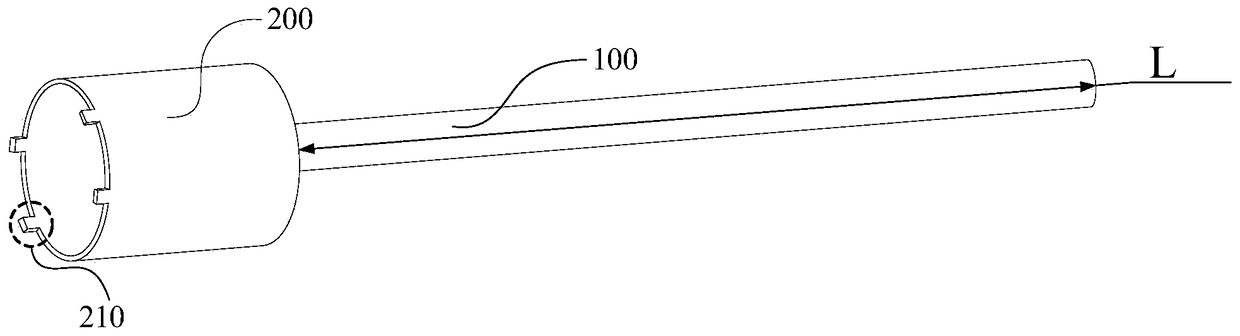

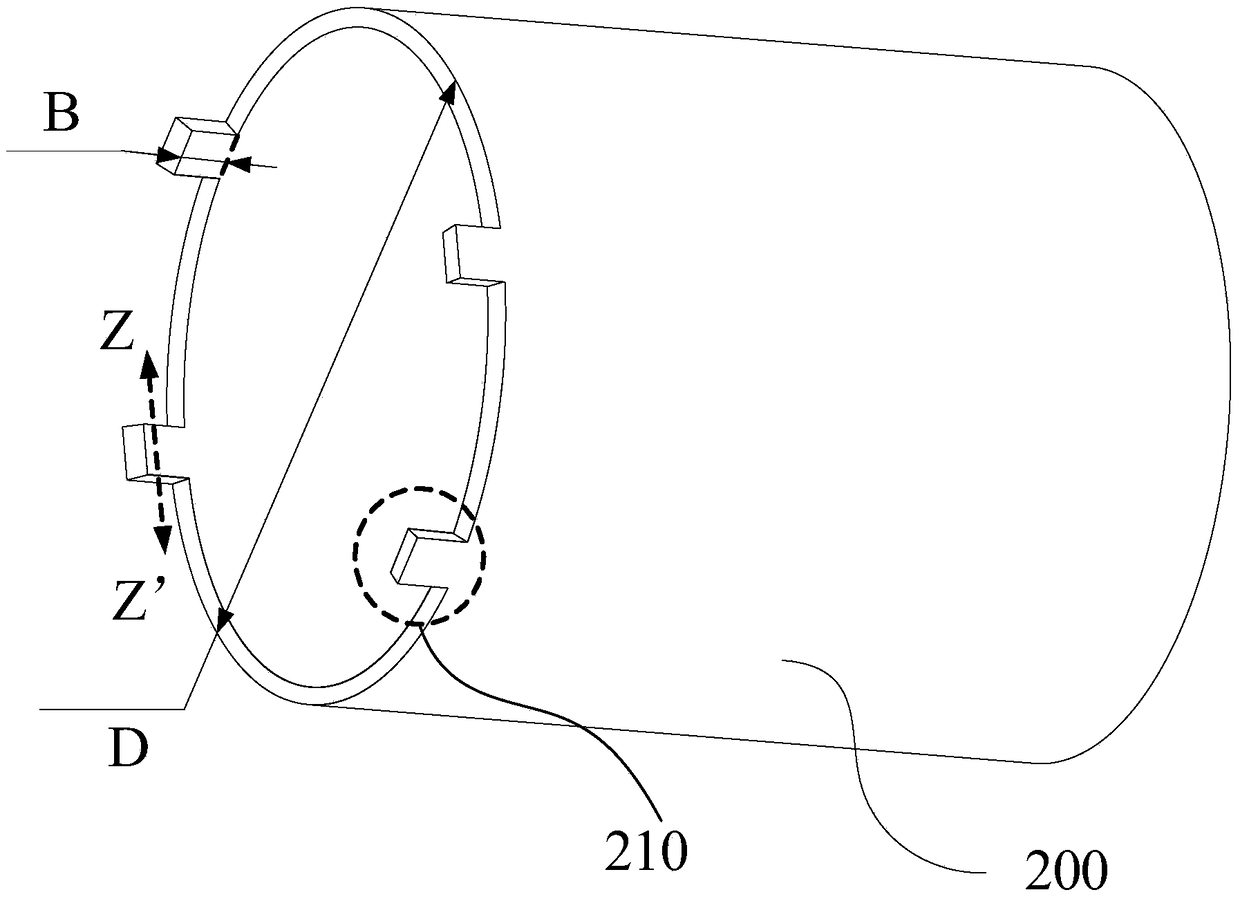

[0027] It can be known from the background art that the operation mode of adjusting the control structure of the particle size adjusting device in the prior art is too complicated, which is not conducive to improving labor efficiency. Now in conjunction with the structure analysis of the particle size adjustment device in the prior art, the reason for the complicated operation:

[0028] Because the control structure of the particle size adjustment device in the bulk material bin has a certain height from the EB furnace cavity. Therefore, when the control structure needs to be rotated to adjust the particle size, the bulk material bin needs to be disassembled from the EB furnace body. Install again after adjustment is complete. Therefore, the operation mode of adjusting the control structure of the particle size adjusting device is very complicated, time-consuming and labor-intensive, increasing labor intensity and reducing labor efficiency.

[0029] In order to solve the tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com