Finished grain rice low-temperature storage method

A technology for low-temperature storage and finished grain, which is applied in the direction of freezing/cooling to preserve seeds, etc., which can solve the problems of storage of finished rice products, achieve good economic and social benefits, simple method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be described in detail below in combination with specific situations.

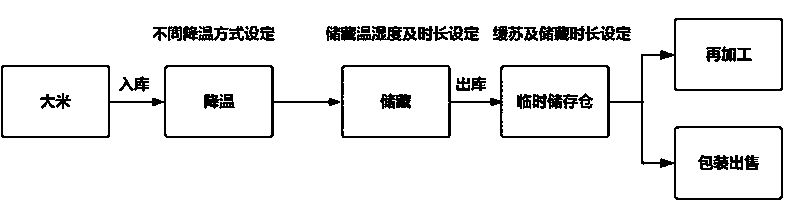

[0009] Depend on figure 1 Shown, when the present invention is concretely implemented, a kind of finished grain rice low-temperature storage method is, paddy is processed into finished rice by conventional method, at first packs in the warehouse, carries out cooling, adopts grain cooling machine under the control of PLC controller , at a cooling rate of 1-1.5°C / d, lower the storage temperature of finished rice to 15°C, under the control of the PLC controller, the humidity in the grain depot is kept at 60-65%RH, and the fatty acid value is 10 -20mg / 100g (KOH dry basis), within 180 days of storage, during the storage period, when the finished rice needs to be delivered from the warehouse, it should be stored in a temporary storage warehouse first, (no temperature control equipment adjustment, affected by the external natural environment) when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com