Layered body of polyimide film and inorganic substrate

A technology of polyimide film and inorganic substrate, applied in the direction of coating, lamination, layered products, etc., can solve the problem of not being able to improve the yield of functional components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

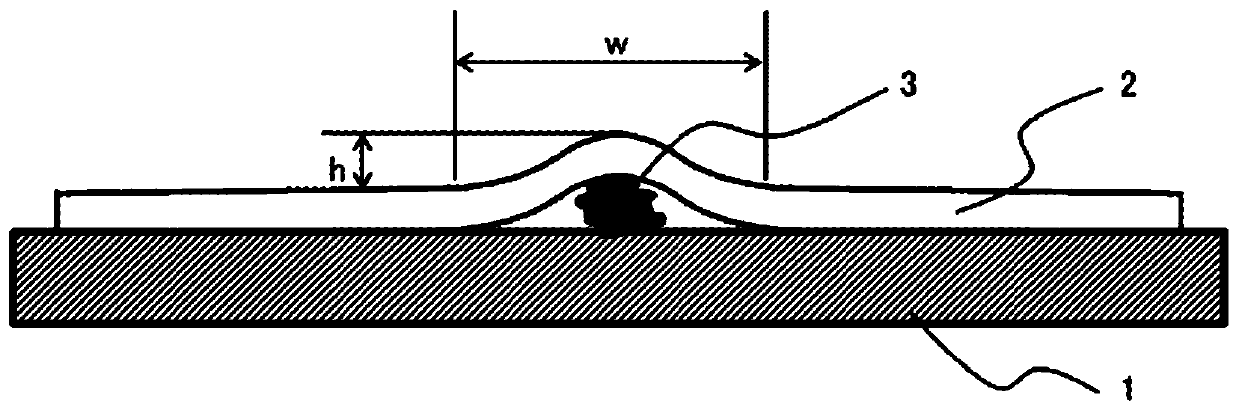

Image

Examples

Embodiment

[0113] Hereinafter, although an Example and a comparative example demonstrate this invention more concretely, this invention is not limited to the following Example. In addition, the evaluation methods, processing methods, operation methods, etc. of the physical properties in the following examples are as follows.

[0114]

[0115] The polymer was dissolved in N-methyl-2-pyrrolidone (or N,N-dimethylacetamide) in such a way that the polymer concentration was 0.2 g / dl, using an Ubbelohde viscometer at 30 °C Assay solution. (When the solvent used for the preparation of the polyamic acid solution is N,N-dimethylacetamide, the polymer is dissolved using N,N-dimethylacetamide and measured.)

[0116]

[0117] For the polyimide film, the film thickness was determined by SEM cross-sectional observation of the cross-section of the laminated body. In addition, unless otherwise stated, the average value of the film thickness of 5 randomly selected places in the area|region from the ...

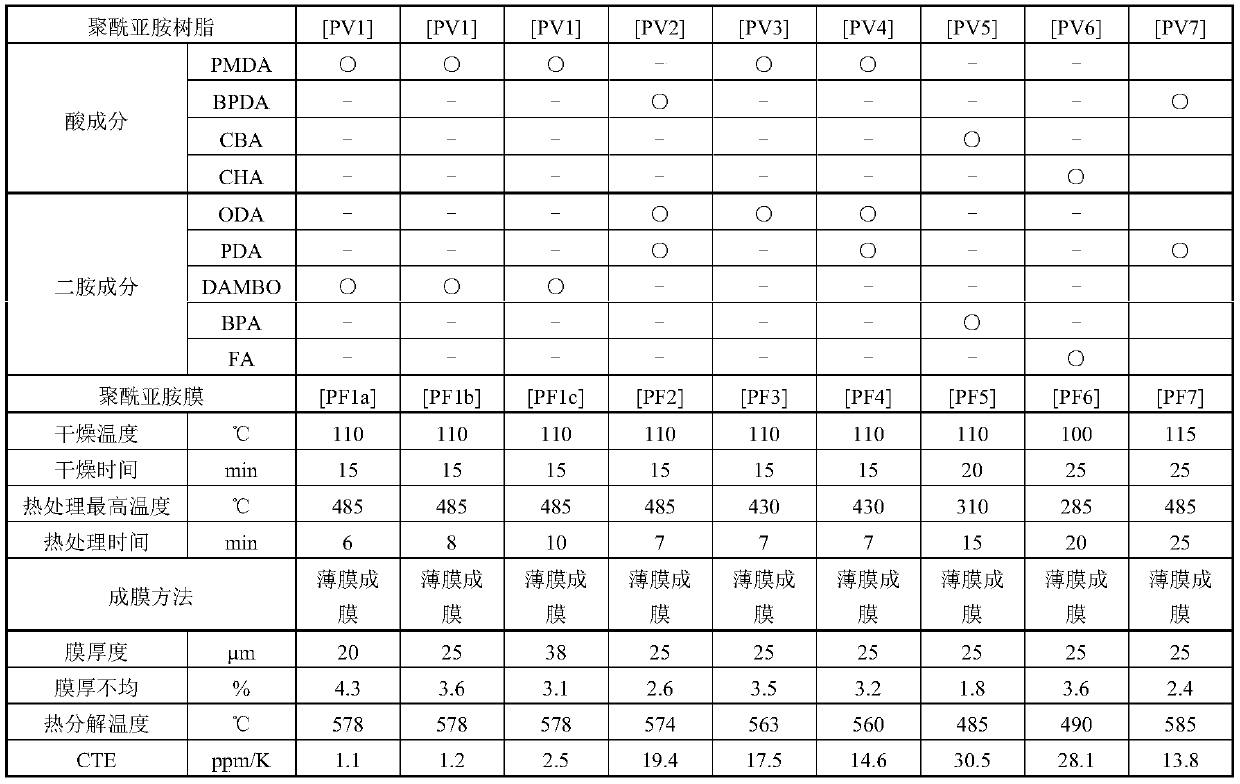

manufacture example

[0148] [Manufacture of polyimide precursor (polyamic acid) solution PV1]

[0149] After substituting nitrogen gas into the reaction vessel equipped with nitrogen gas introduction tube, thermometer and stirring rod, add 223 parts by mass of 5-amino-2-(p-aminophenyl) benzoxazole, 4416 parts by mass of N,N-dimethylacetamide After completely dissolving it, 217 parts by mass of pyromellitic dianhydride was added and stirred for 24 hours at a reaction temperature of 25° C. to obtain a brown viscous polyamic acid solution [PV1].

[0150] [Manufacture of polyimide precursor (polyamic acid) solution PV2]

[0151] After substituting nitrogen gas into the reaction vessel equipped with a nitrogen gas introduction tube, a thermometer, and a stirring bar, 398 parts by mass of 3,3',4,4'-biphenyltetracarboxylic dianhydride as tetracarboxylic dianhydride, terephthalic dianhydride Dissolve 132 parts by mass of amine and 30 parts by mass of 4,4'-diaminodiphenyl ether in 4600 parts by mass of N,...

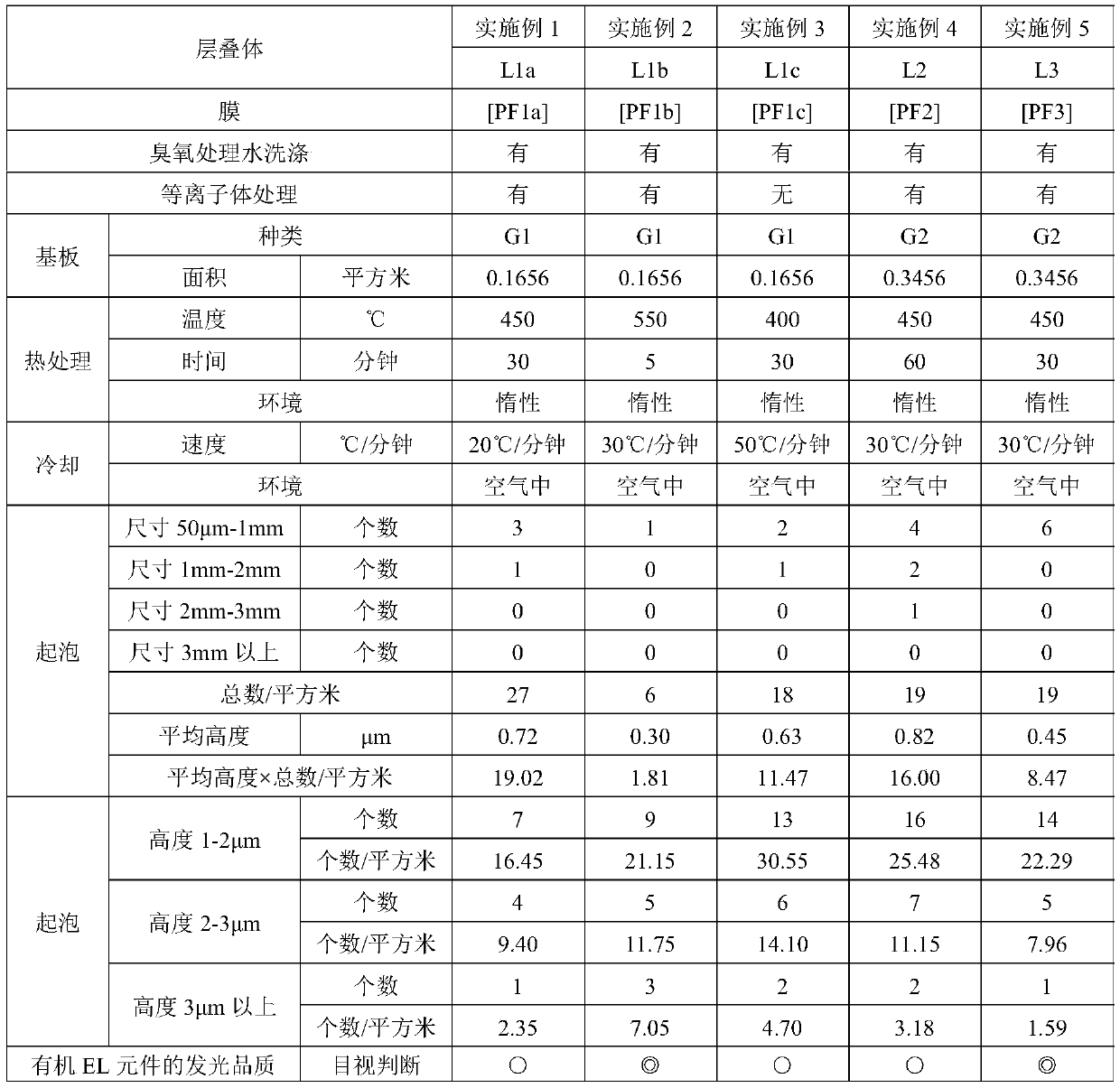

Embodiment 1

[0193] The polyimide film [PF1a] which is a polyimide film is plasma-treated, and the polyimide film is overlapped with the silane coupling agent-treated surface of the inorganic substrate treated with the silane coupling agent, After temporarily crimping with a roller laminator, set it in a clean workbench, place it on a hot plate whose temperature is adjusted to 150°C in such a way that the inorganic substrate side is in contact with the hot plate, and perform heat treatment for 3 minutes to obtain polyamide A laminate of an imide film and an inorganic substrate. The obtained laminate of the polyimide film and the inorganic substrate was stored in an environment with a temperature of 20 to 25° C. and a relative humidity of 65±30% for 12 hours or more.

[0194] The obtained laminate of the polyimide film and the inorganic substrate was heat-treated in an inert furnace at 450° C. for 30 minutes. Take it out from the furnace, place it on a separately prepared copper plate whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com