A turning control method, device and machining lathe with variable feed speed

A technology of feed speed and control method, applied in the direction of program control, digital control, general control system, etc., can solve problems such as affecting the reliability of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

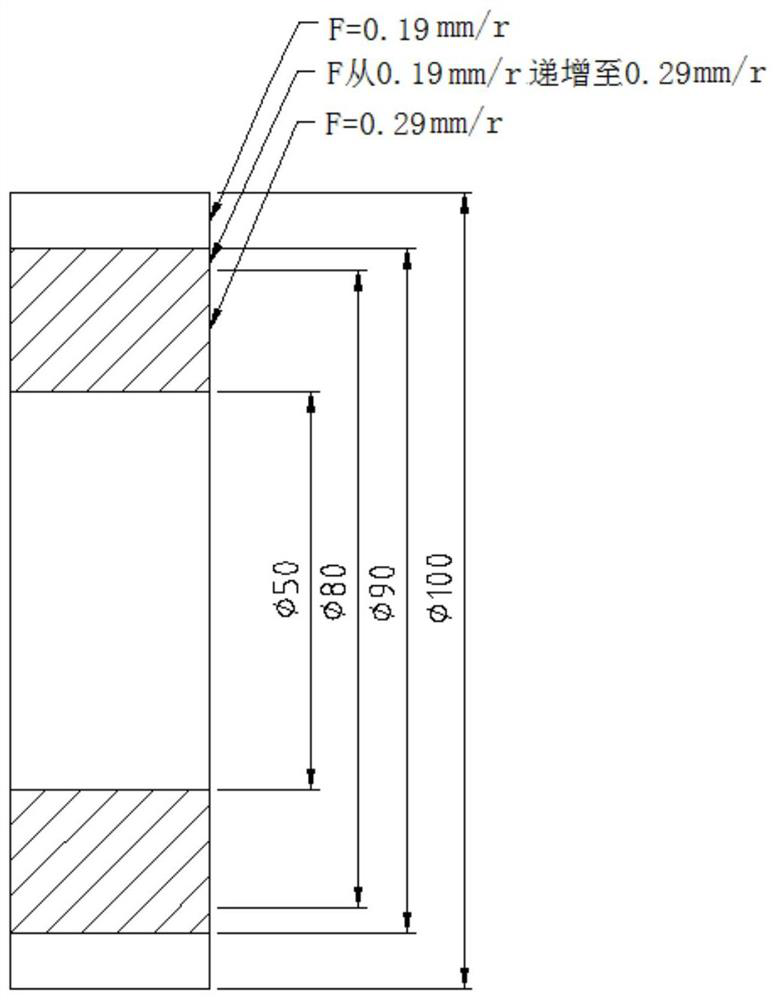

[0083] This embodiment provides a turning control method with variable feed speed, which is used for turning the surface of the part to be processed, and is performed according to the following steps:

[0084] Before performing the following steps, first select the tool according to the actual situation, from the tool material, machine holder blade form, and tool nose arc angle. In this example, the workpiece is heat-hardened low-carbon alloy steel, and the material is 20CrMnTiH, so the blade material is selected as CBN blade. There is no interference in the end face processing, so the CNGA120408 standard blade with good strength and stable clamping is selected.

[0085] Secondly, the Taylor formula to determine the tool durability can be used to determine whether the method of increasing the feed rate at a constant speed can not only ensure the quality, but also improve the processing efficiency. When a0, it is necessary to calculate the minimum feed speed that meets the takt...

Embodiment 2

[0140] This embodiment provides a turning control device with variable feed speed, which is used for turning the surface of the part to be processed, including a partition module and a turning control module:

[0141] The partition module is used to partition the surface of the part to be processed according to the processing requirements of the surface of the part to be processed to obtain multiple processing areas; the processing requirements include different roughness processing or continuous-intermittent processing;

[0142] The turning control module is used for turning two adjacent processing areas, specifically including the variable speed area determination sub-module and the vehicle speed control sub-module;

[0143] The variable speed area determination sub-module is used to determine the variable speed area at the junction of two adjacent processing areas to obtain the variable speed area;

[0144] Take the area other than the variable speed area in the processing ...

Embodiment 3

[0168] This embodiment provides a processing lathe, including the turning control device with variable feed speed in the second embodiment.

[0169] In this embodiment, a processing lathe is disclosed, which includes a turning control device with variable feed speed, so that during the processing of the processing lathe, the surface roughness of the processed part is guaranteed, and the processing speed is improved. Tool life in lathes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com