Flow field precise control system for DC transient impact type transonic wind tunnel and control method

A precise control, transonic technology, applied in the field of wind tunnel testing, can solve the problems of inaccurate resistance measurement accuracy, difficulty in accurately obtaining the resistance increment of external objects, difficulty in meeting the design requirements of aircraft, etc., and achieve the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

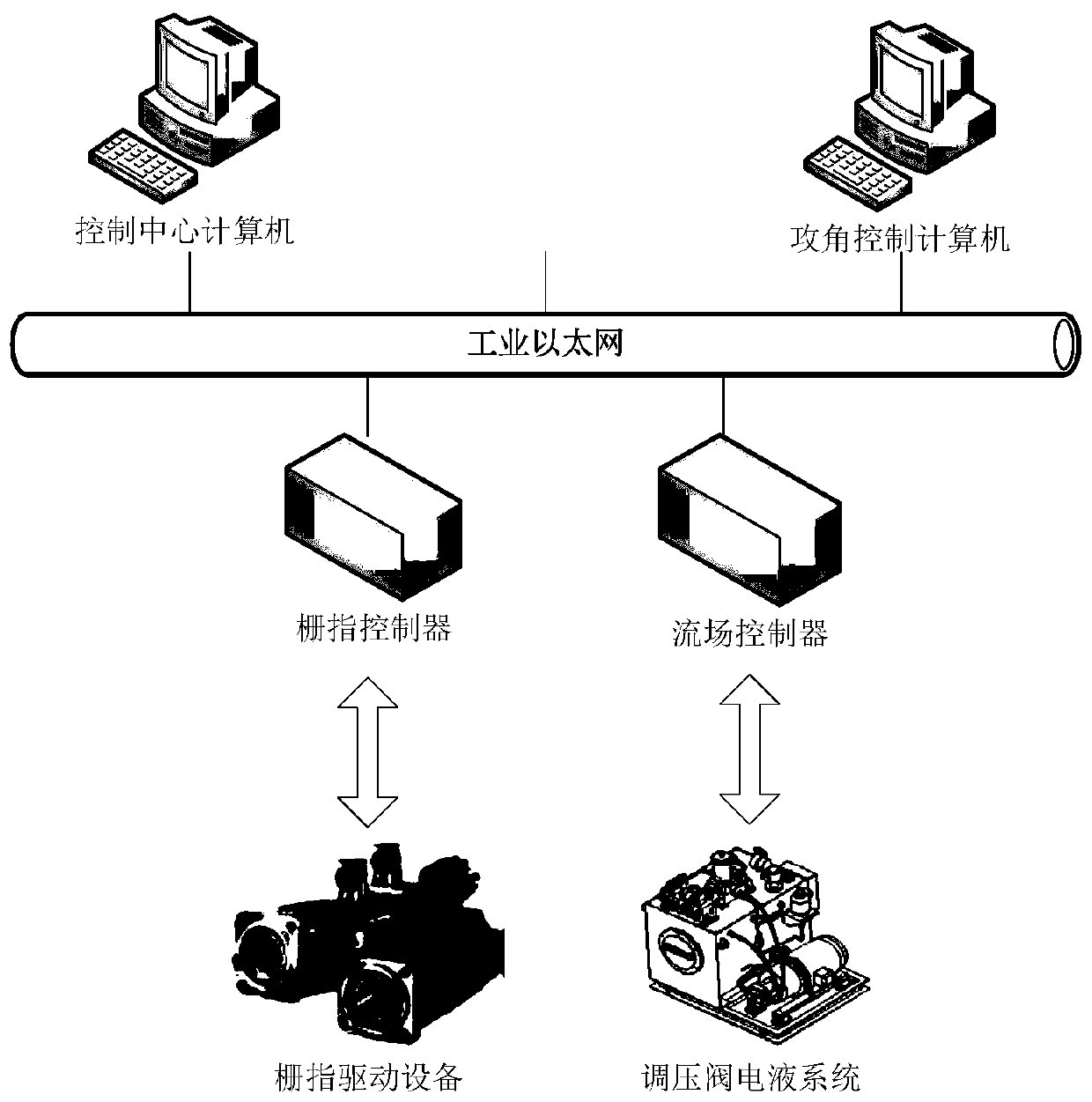

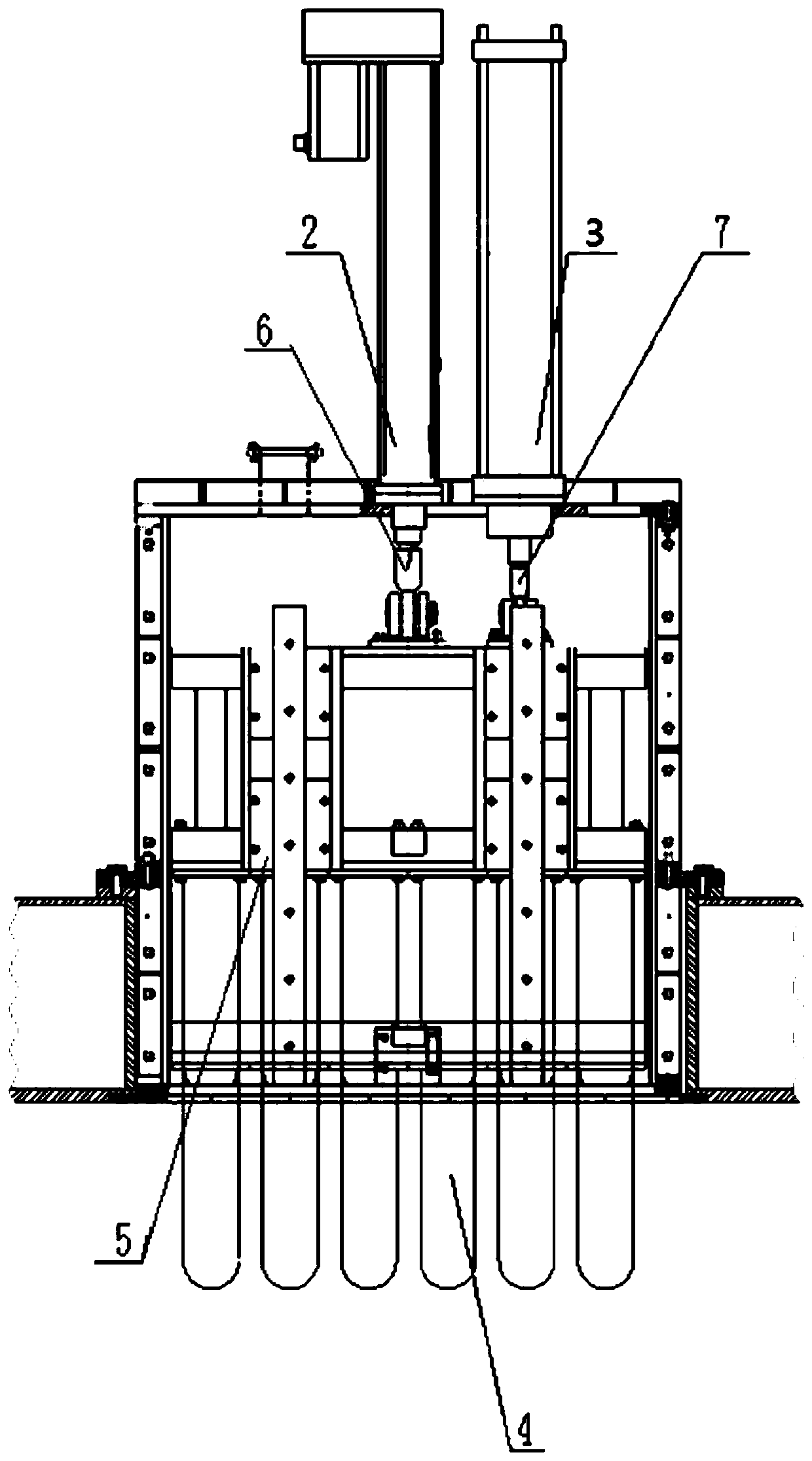

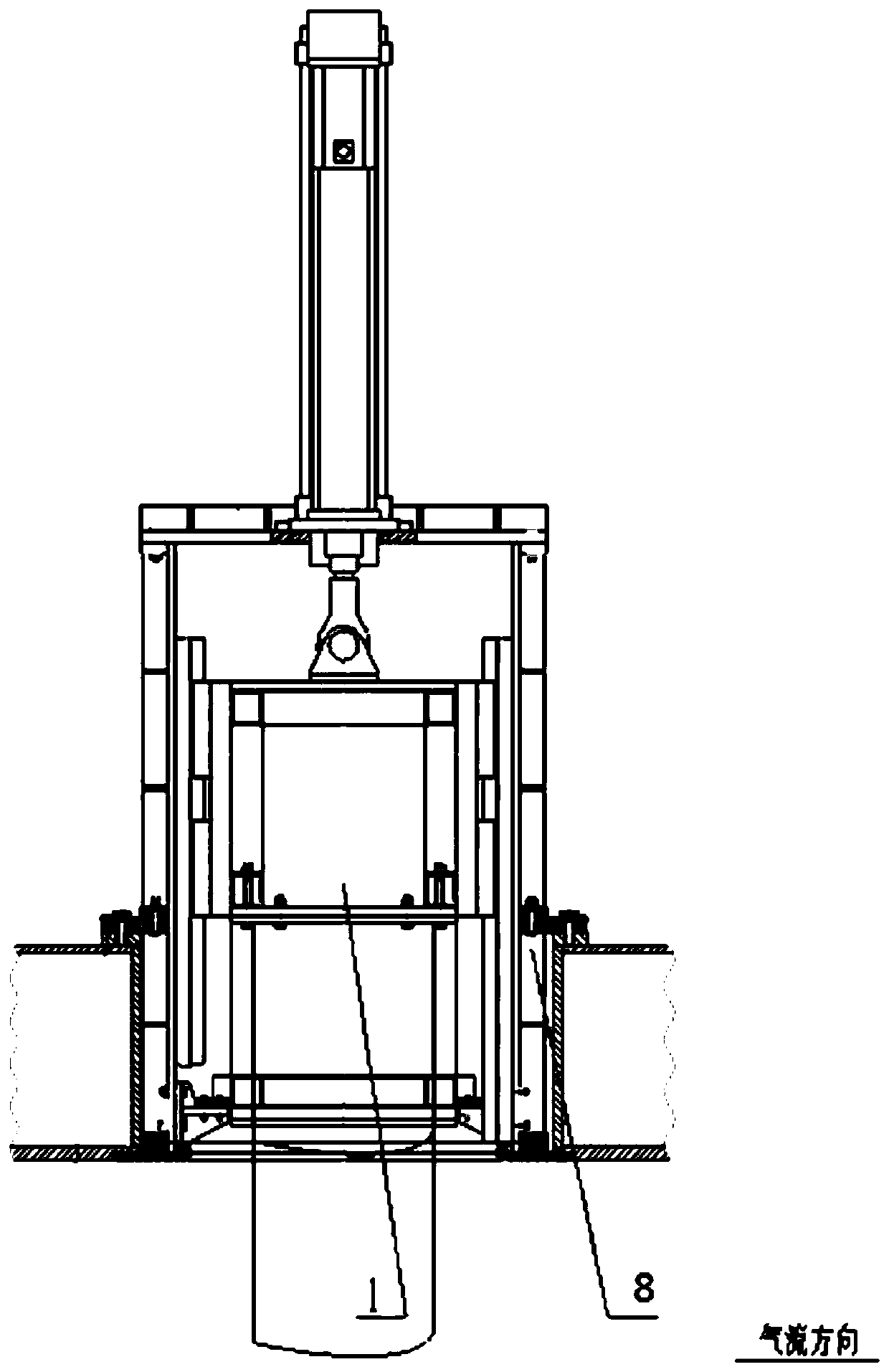

[0056] A flow field precise control system of a DC impulsive transonic wind tunnel, such as figure 1 As shown, it includes control center computer, tapping foot control computer, grid finger controller, flow field controller, grid finger drive equipment and pressure regulating valve electro-hydraulic system; the control center computer is bidirectionally connected to the grid finger controller through Ethernet , the grid finger controller is bidirectionally connected to the grid finger drive equipment, the tapping foot control computer is bidirectionally connected to the flow field controller through Ethernet, and the flow field controller is bidirectionally connected to the electro-hydraulic system of the pressure regulating valve;

[0057] Working process: The control center computer is connected to the grid finger controller through the industrial Ethernet of the test site to realize the control of the grid finger drive equipment, and at the same time control the electro-hyd...

specific Embodiment approach 2

[0064] A control method implemented on the flow field precise control system of a direct current impulse transonic wind tunnel based on the specific implementation mode 1, such as Figure 4 shown, including the following steps:

[0065] Step 1, start, first determine whether the reading of the line sensor is normal, if it is abnormal, it will alarm and end, otherwise continue to step 2;

[0066] Step 2. Before blowing, adjust each node of the super-expansion section of the wind tunnel to a given initial size, and then move the grid finger section to the preset position;

[0067] Step 3. Open the pressure regulating valve to control the total pressure in the stable section to ensure that the total pressure in the stable section is stable within the error band;

[0068] Step 4. After the total pressure is stabilized, use the gate finger controller to control the gate finger drive equipment to perform Mach number control, so that the Mach number remains within the error band;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com