Air separation device and method utilizing LNG cold energy

An air separation device and cold energy technology, applied in the field of air separation, can solve the problems of low cascade utilization efficiency, waste of compression heat of raw material air compressors, etc., and achieve good economic benefits and emission reduction benefits, and reduce unit energy consumption and save energy. The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

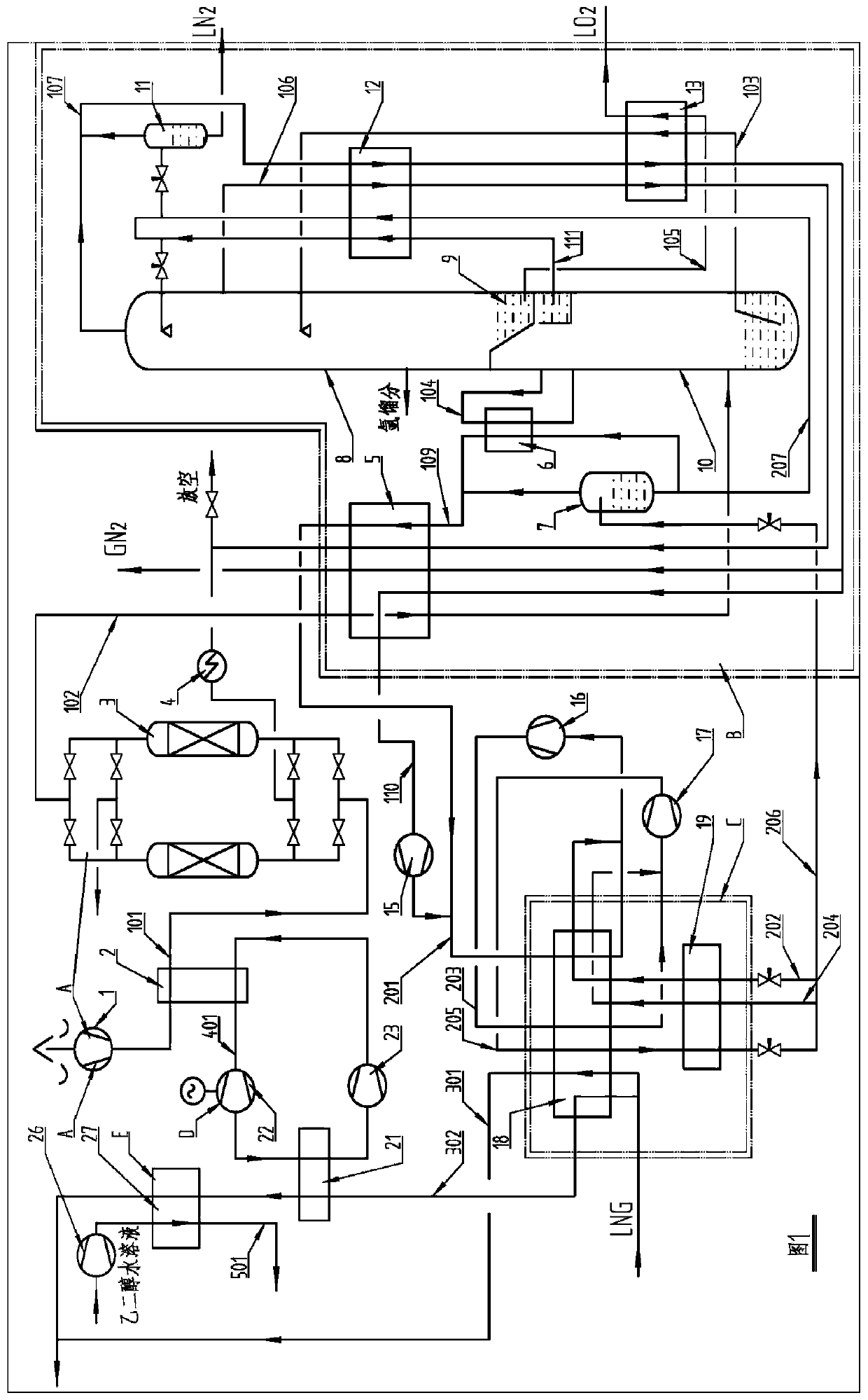

Embodiment 1

[0020] Embodiment 1: An air separation plant utilizing LNG cold energy capable of generating electricity at the same time, including an air compression purification system A, a large cold box system B, a small cold box system C, a refrigerant circulation system D and a coolant circulation system E.

[0021] The air compression and purification system A is used to compress and purify the raw air, which includes a raw air compressor 1 , a raw air cooler 2 and a purifier 3 arranged in sequence. The feed air cooler 2 includes an intercooler and a final cooler. Refrigerant is used as the refrigerant in the feed air cooler 2 .

[0022] The large cold box system B is used to rectify the compressed and purified raw material air 102 to obtain air separation products. The large cold box system B includes a main heat exchanger 5 and a rectification tower system arranged in sequence, and the rectification tower system includes an upper tower 8, a lower tower 10, a main condensation evapo...

Embodiment 2

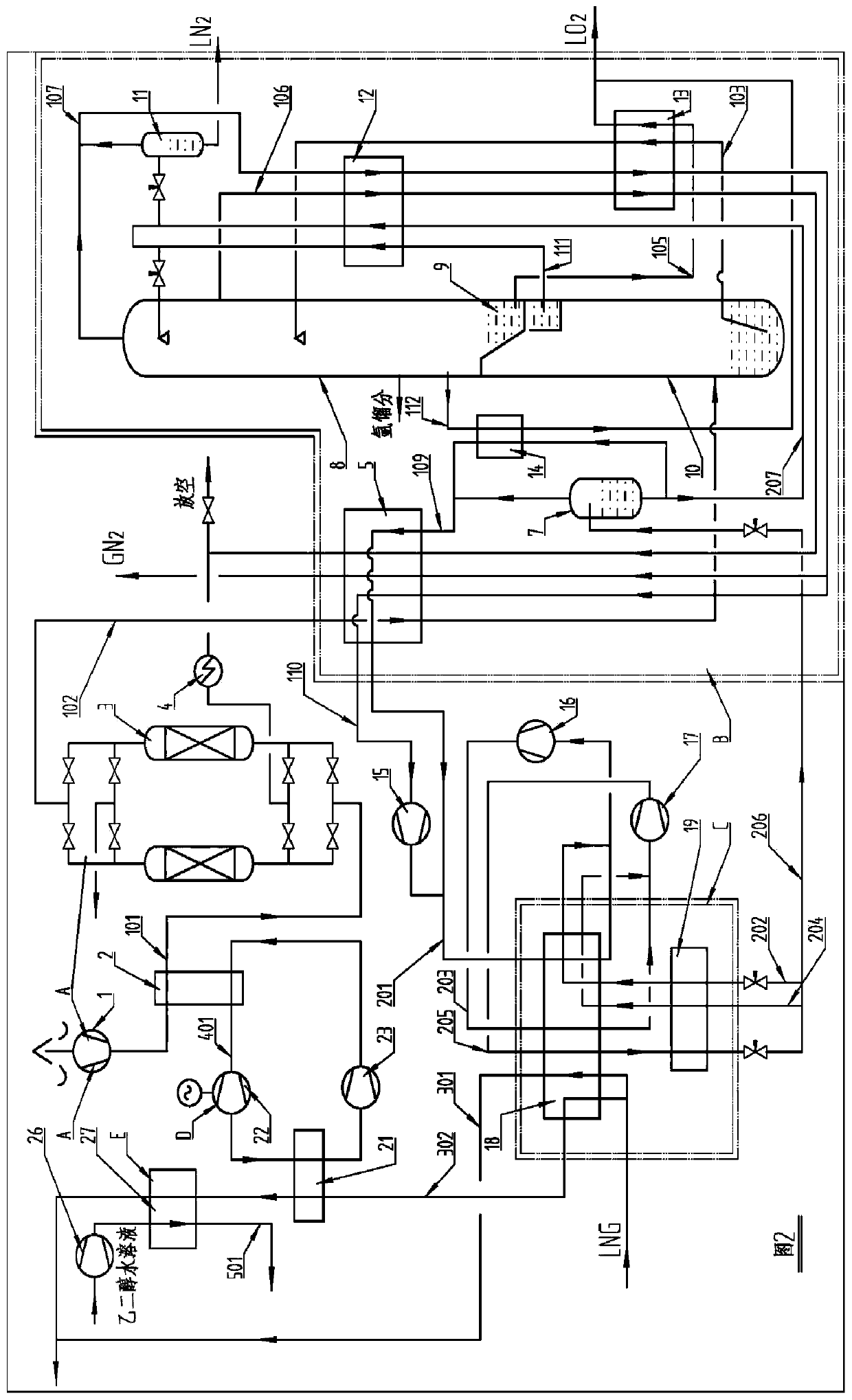

[0034] Embodiment two: as attached figure 2 As shown, an air separation method and device utilizing cold energy of LNG capable of power generation at the same time, the main difference from Embodiment 1 is that the upper tower 8 mainly produces gaseous oxygen 112 rather than liquid oxygen 105 . A part of the deoxygenated liquefier 14 after throttling the liquid nitrogen 206 from the small cold box system C liquefies and supercools the gas oxygen 112 drawn from the bottom of the upper tower to make it a liquid oxygen product.

[0035] The low-temperature and low-pressure nitrogen compressor 15 can also be omitted, and the liquid nitrogen output of the device will decrease at this time, and the path of the low-temperature and low-pressure nitrogen 110 can also be canceled accordingly.

Embodiment 3

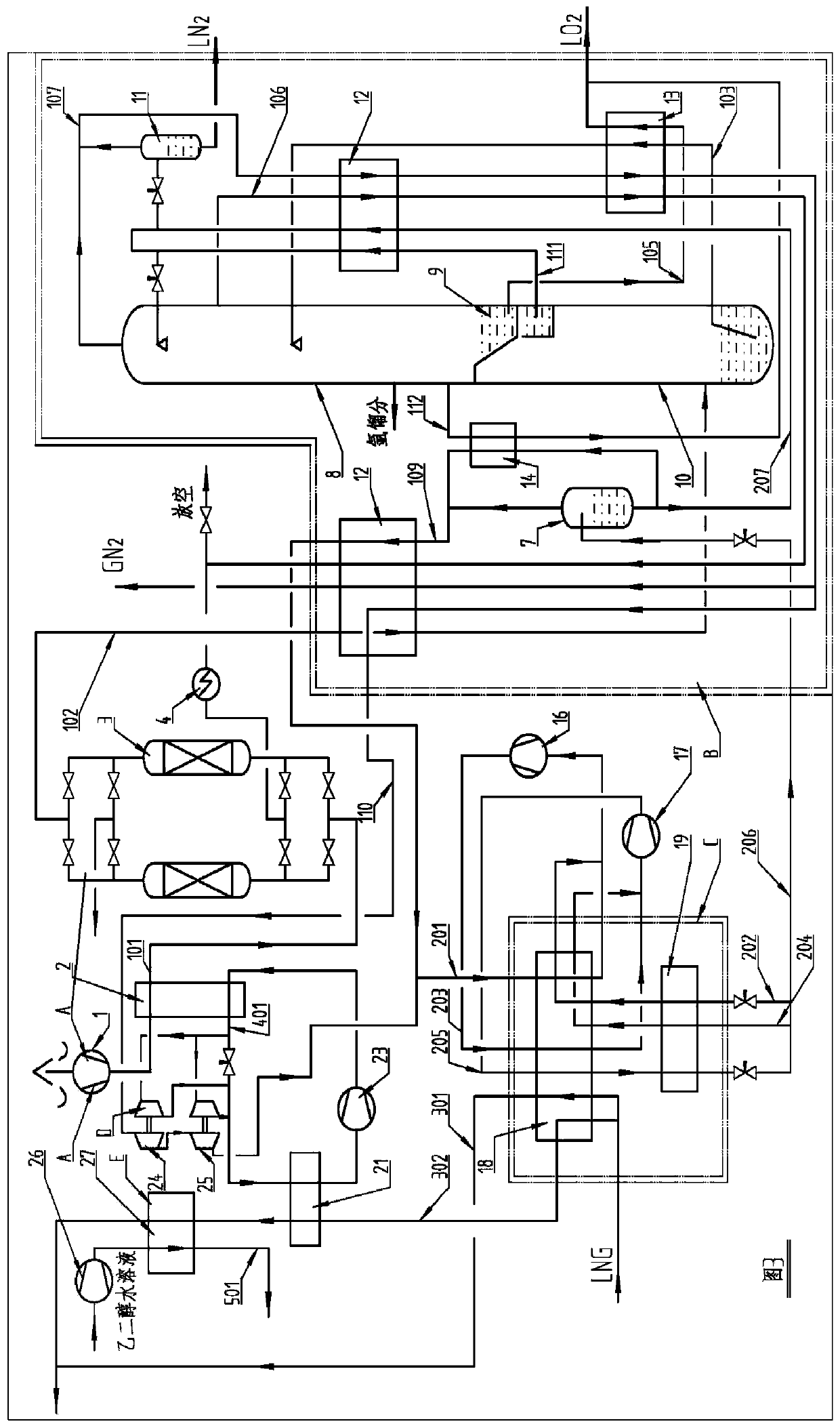

[0036] Embodiment three: as attached image 3 As shown, a kind of air separation method and device utilizing LNG cold energy that can pressurize low-temperature and low-pressure nitrogen to the pressure required by the process at the same time, its main difference from Embodiment 1 is: low-temperature and low-pressure nitrogen 110 is pressurized and permeated with refrigerant Flat expansion unit, that is, two parallel refrigerant supercharging turboexpanders 24, 25 are compressed in series at the supercharging end to make it reach the pressure required by the process. The expansion ends of the refrigerant supercharging turboexpansion units 24 and 25 are connected in parallel, and the boosting ends are connected in series. The refrigerant 401 that exits the heat exchanger 2 is divided into three routes: one route goes to the booster turbo expander 24, the other route goes to the booster turbo expander 25, and the rest of the refrigerant is throttled and combined with the booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com