Method for producing high-speed belts by crochet machine

A crochet machine and high-speed belt technology, which is applied in the field of crochet machine production of high-speed belts, can solve problems such as difficulty in training employees, and achieve the effect of high efficiency and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

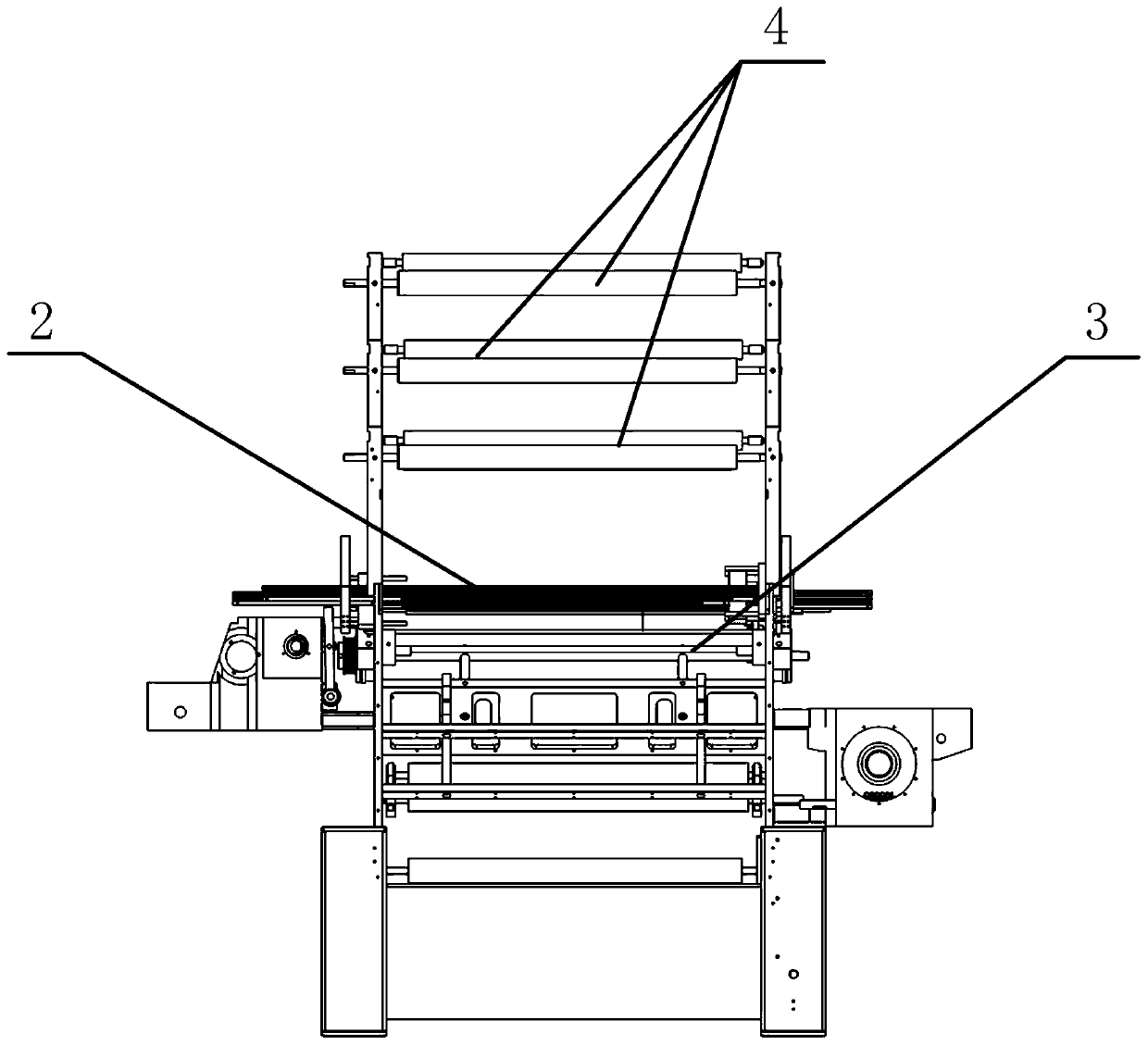

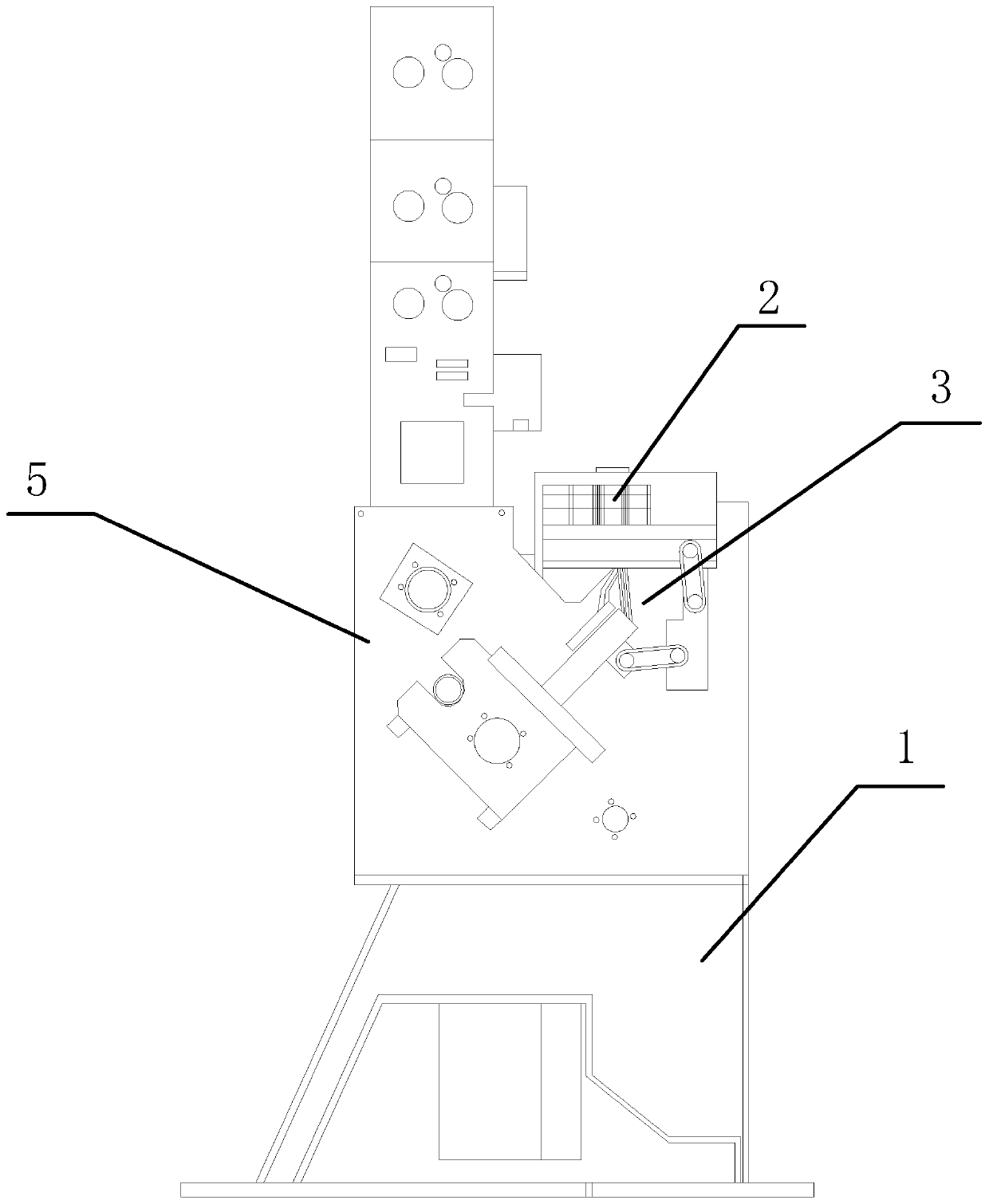

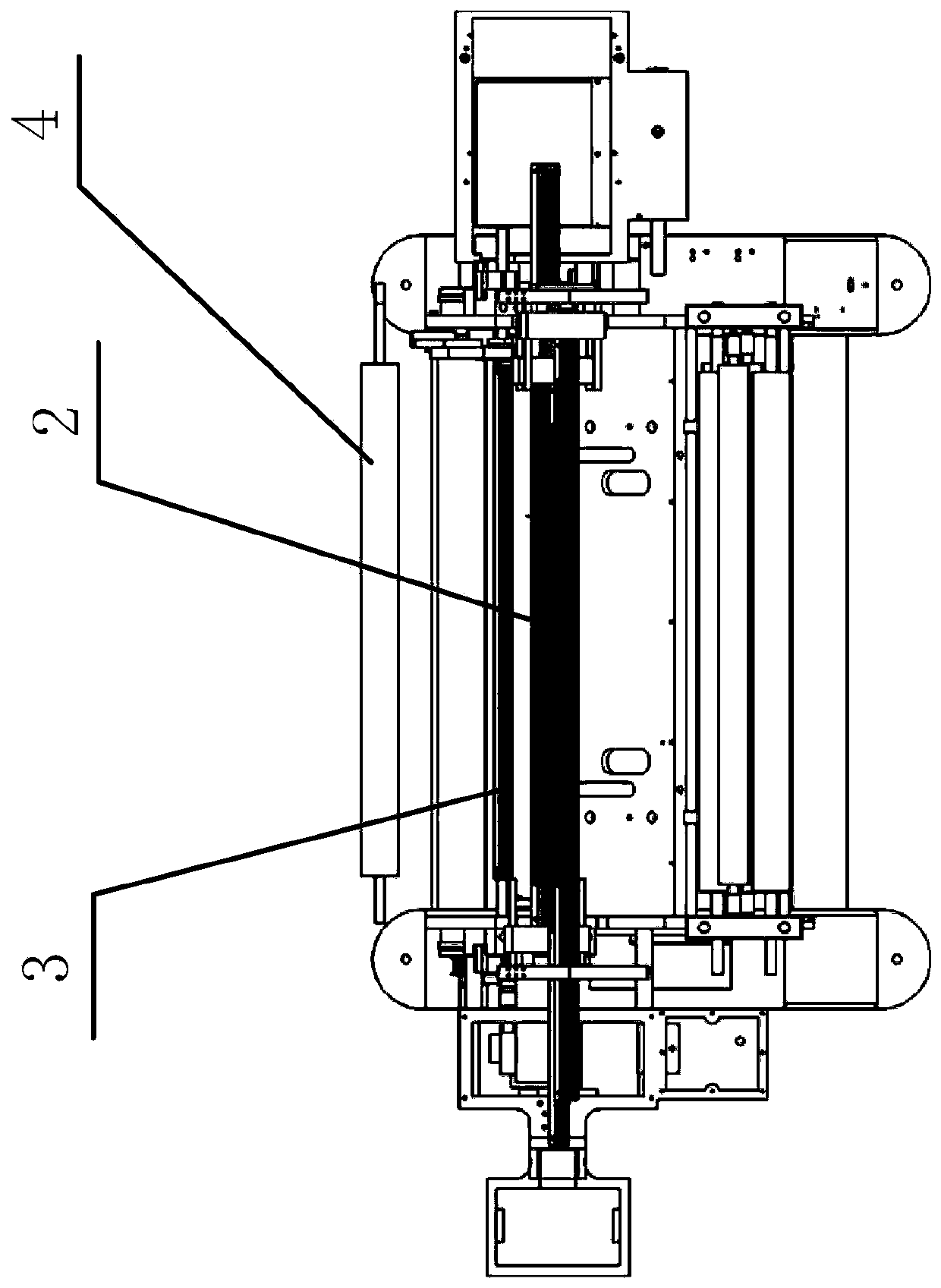

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the crochet machine includes a frame 1, and a brown sheet transmission system 2 and a needle bed system 3 arranged on the frame 1. The needle bed system 3 includes a high-speed needle plate, an eye needle plate and a warp needle. The high-speed needles 31 on the high-speed needle needle board reciprocate in the direction of 5-90° inclination to the horizontal plane, the eye needles 32 on the eye needle needle board are parallel to the high-speed needles 31, and the eye needles 32 are aligned with the The corresponding high-speed needle 31 is used as the center to perform self-winding motion;

[0037] The palm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com