Dark-system photopolymerizable composition

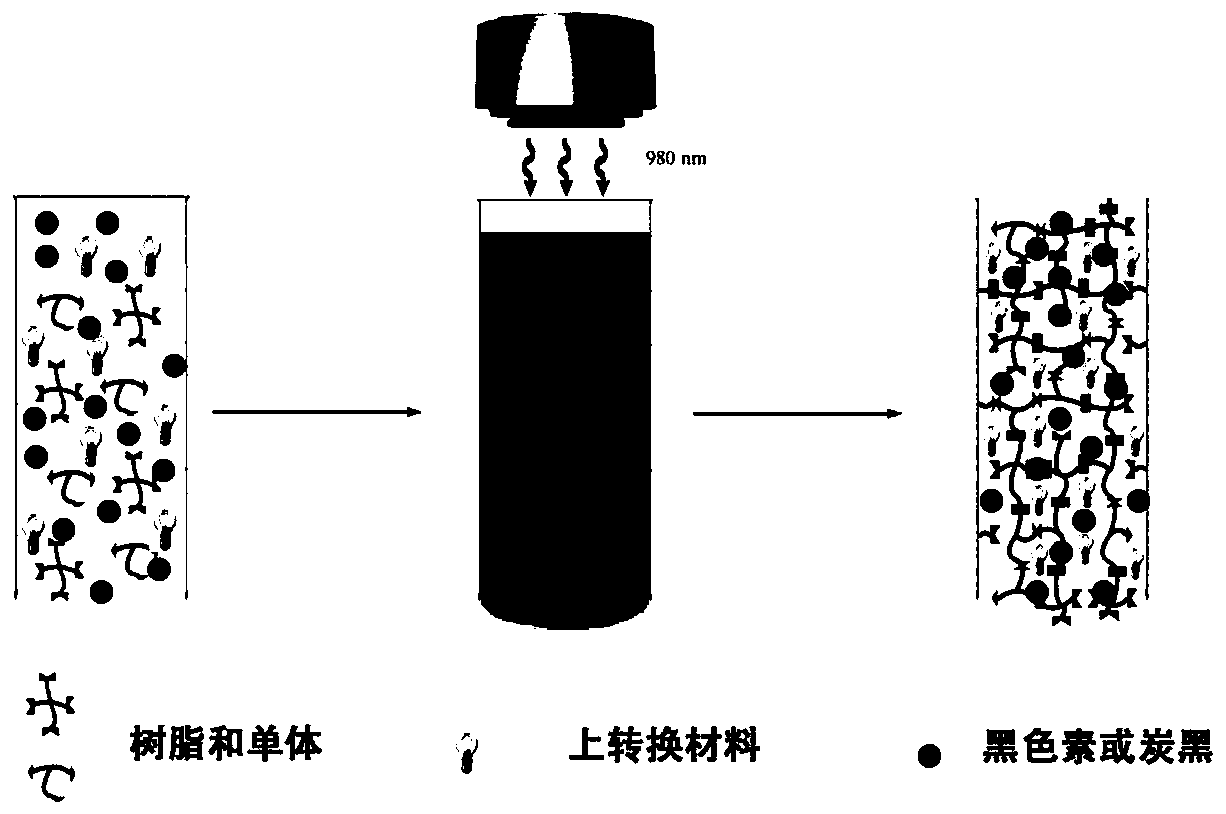

A photopolymerization composition and photopolymerization technology, applied in the field of photopolymerization materials, can solve problems such as limiting the application of photocuring technology, limited penetration ability, and inability to penetrate light, so as to improve the depth of photopolymerization and improve mechanical properties. simple and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A composition for realizing deep photopolymerization of a black system, the components contained in the composition and the parts by mass of each component are:

[0038] 75 parts of polyurethane acrylate,

[0039] 20 parts of trimethylolpropane triacrylate,

[0040] 3 parts of bis-2,6-difluoro-3-pyrrole phenyl titanocene,

[0041] 0.1 parts of melanin,

[0042] Up conversion material NaYF 4 2 servings.

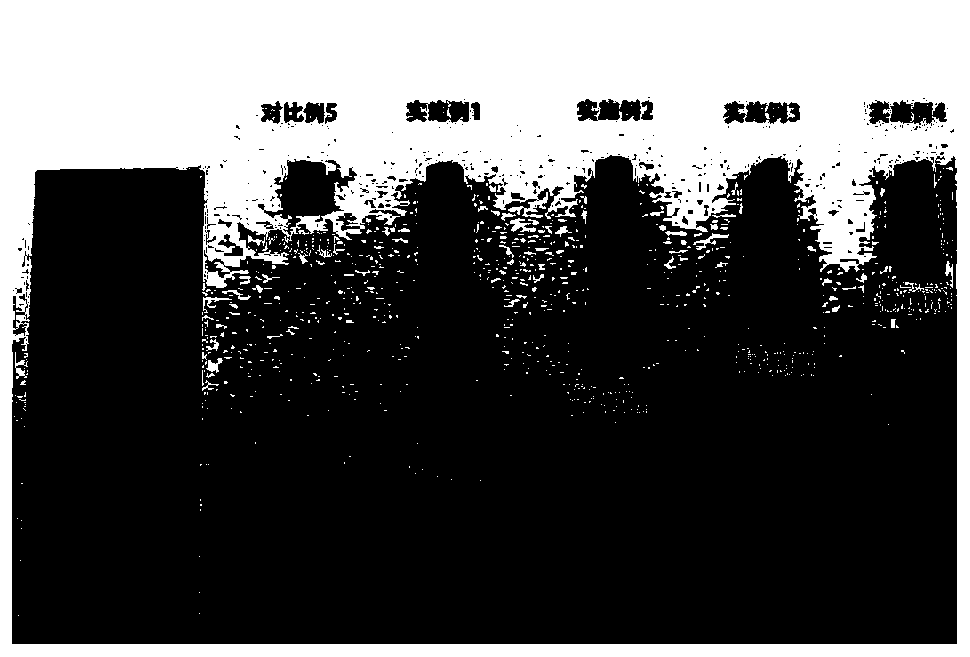

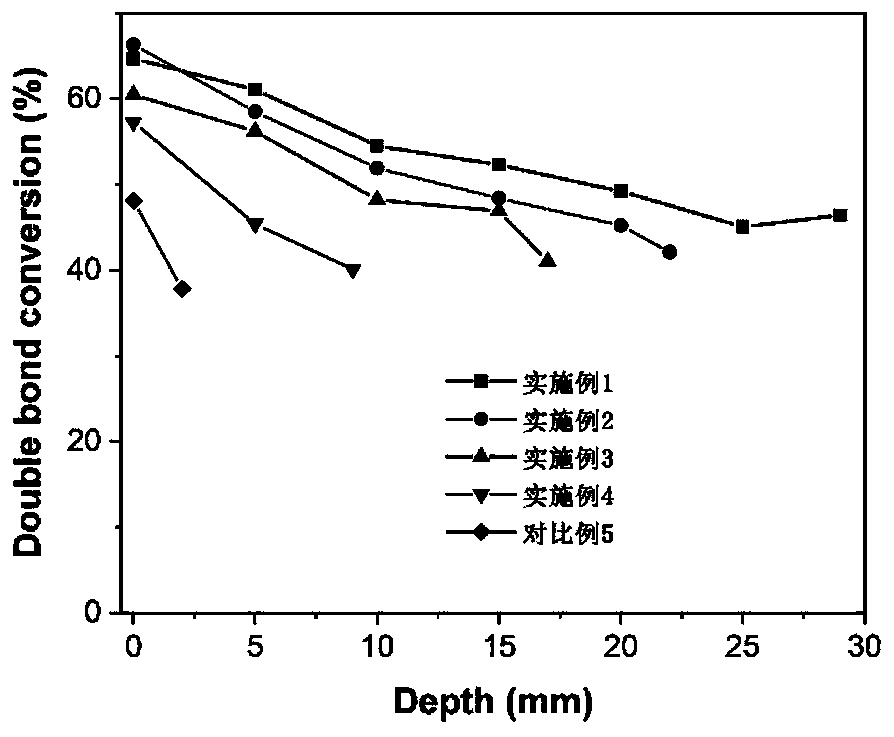

[0043] Mix the above composition evenly and add it into the test tube, place it vertically and use the emission wavelength 980nm, the energy density is 10W / cm 2 The light source is irradiated on the top of the test tube downward, and after 5 minutes, it is solidified to obtain a column with a certain length. When the melanin content is 0.1 part, the test result is shown in figure 2 As shown, the length of the column is 29mm, and the conversion rate of the double bond is as image 3 As shown, about 60%. Above-mentioned composition prepares tensile sample bar, ca...

Embodiment 2

[0045] A composition for realizing deep photopolymerization of a black system, the components contained in the composition and the mass parts of each component are the same as those in Example 1, the difference is that the content of melanin is changed to 0.3 parts, obtained under the same light conditions Column length, such as figure 2 22mm shown, double bond conversion rate as image 3 As shown, about 56%. Above-mentioned composition prepares tensile sample bar, carries out mechanical test, and tensile strength is as follows: Figure 4 , about 34MPa.

Embodiment 3

[0047] A composition for realizing deep photopolymerization of a black system, the components contained in the composition and the mass parts of each component are the same as those in Example 1, the difference is that the content of melanin is changed to 0.5 parts, obtained under the same light conditions Column length, such as figure 2 17mm shown, double bond conversion rate as image 3 As shown, about 52%. Above-mentioned composition prepares tensile sample bar, carries out mechanical test, and tensile strength is as follows: Figure 4 , about 36MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com