Synthetic method of empagliflozin

A synthetic method and compound technology, applied in drug combination, organic chemistry, metabolic diseases, etc., can solve the problems of low total yield, high cost, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

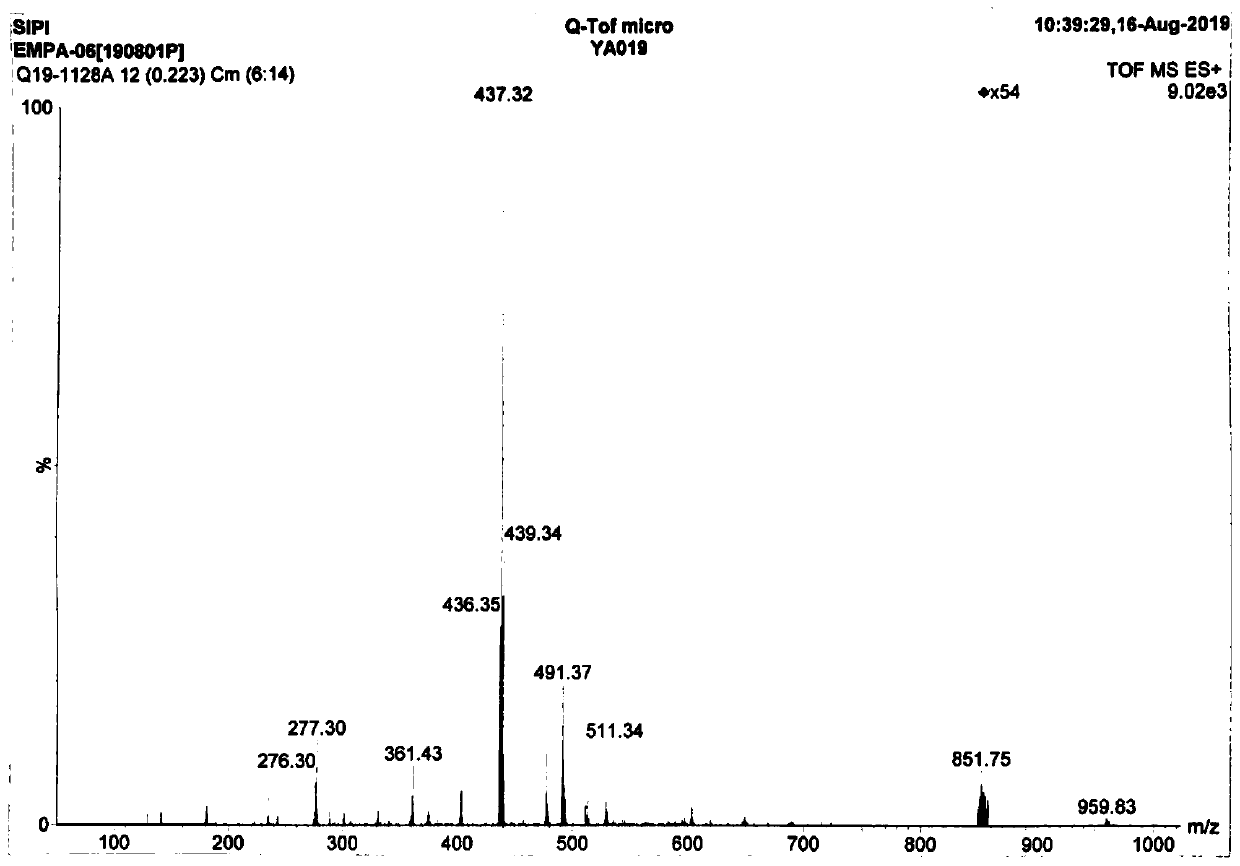

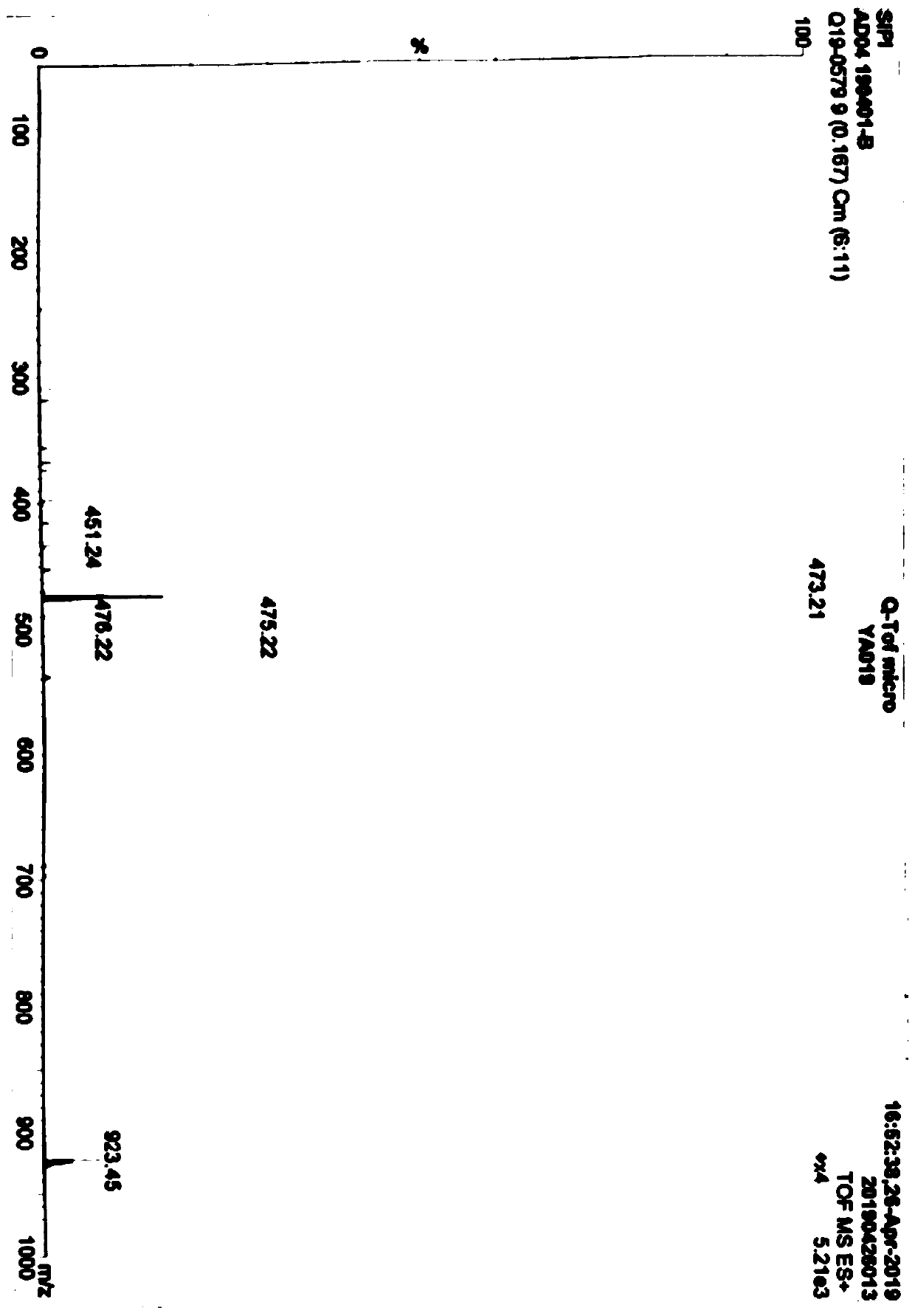

[0068] Embodiment 1. synthesis ((2-chloro-5-bromophenyl) (4-fluorophenyl) ketone) (formula 3)

[0069]

[0070] Synthetic formula 2: Add 235.5 g of formula 1; 1 L of dichloromethane; 10 ml of DMF into the reaction bottle. Lower the temperature to below 10°C. 140 g of oxalyl chloride was added dropwise. After the dropwise addition, the temperature was controlled below 20°C for 120 min, and the reaction was detected by TLC. The reaction solvent dichloromethane and excess oxalyl chloride were removed by concentration to obtain 252.8 g of white solid formula 2.

[0071] Synthesis formula 3: add 1L of dichloromethane into the reaction bottle, and then add 190g of fluorobenzene. Cool the ice water to below 0°C. Add 185 g of anhydrous aluminum trichloride under temperature control. After the addition, add formula 2 dropwise (252.8 g dissolved in 1 L of dichloromethane). After the addition was completed, the reaction was carried out at room temperature for 5 hours, and the re...

Embodiment 2

[0072] Example 2. Synthesis of [4-[[(3S)-tetrahydro-3-furan] oxy]phenyl]-(5-bromo-2-chlorophenyl) ketone (formula 4)

[0073]

[0074] Add 250g of the compound of formula 3 into the reaction bottle, then add 750ml of tetrahydrofuran to dissolve, and then add 78g of (S)-3-hydroxytetrahydrofuran. Ice water cools down below 0°C. Potassium tert-butoxide solution (122 g of potassium tert-butoxide dissolved in 1 L of tetrahydrofuran) was added under temperature control. After the addition was complete, the reaction was carried out at below 10° C. for 2 hours, and the reaction was complete as detected by TLC. The reaction solution was poured into ice water, stirred and added with isopropyl ether for extraction. Washed twice with saturated sodium chloride until neutral, dried over anhydrous magnesium sulfate, filtered and concentrated to obtain a residue purified with acetone to obtain 259.7 g of the compound of formula 4 as a white solid, with a yield of 85.3%.

Embodiment 3

[0075] Example 3. Synthesis of (S)-3-(4-(5-bromo-2-chlorobenzyl)phenoxy)tetrahydrofuran (Formula 5)

[0076]

[0077]

[0078] Add 247g of the compound of formula 4 and 2L of tetrahydrofuran into the reaction flask. Lower the temperature to below 20°C. 159 g of potassium borohydride was added under temperature control. After the addition, 193 g of anhydrous aluminum trichloride was added in batches under temperature control below 20°C. After the addition, the reaction was refluxed for 6 hours, and the reaction was detected by TLC. The reaction solution was poured into ice water. Add dilute hydrochloric acid dropwise. Extracted with ethyl acetate, dried and concentrated to obtain a residue purified with ethanol to obtain 193.5 g of a white compound of formula 5 with a yield of 81.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com